Description

2500L Sanitary Grade 2 Vessel Beer Brewhouse equipment for sale

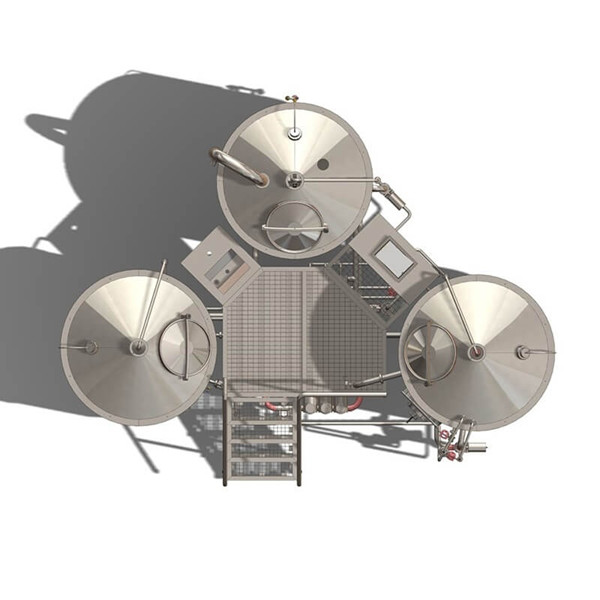

2500L Sanitary Grade 3 Vessel Beer Brewhouse equipment for sale

| Product description: |

According to client’s needs, various combinations of brewhouse can be offered as followings:

2 vessel, 3 vessel and 4 vessel

Heating Methods:steam heating,electric heating and direct heating

| Beer brew process |

| (1) Malt Mill

The two roller mill crushes the malted barley to the desired coarseness. |

| (2) Hot Liquor Tank

Used to recover energy and heat the water (liquor) needed for recirculation and sparging water onto the grain bed to convert starches to sugar. |

| (3) Mash / Lauter Tun

Used to combine grist and hot water. A false bottom is then used to extract the clear wort from the malted barley. The spent grains left over can be used for animal feed. |

| (4) Brew kettle / Whirlpool Tun

The wort is boiled to a desired specific gravity and hops are added for flavor and bitterness. After boiling the wort is whirlpooled to collect soluble proteins in the center of the kettle. The clear wort is then pumped through the heat exchanger and into the fermenter. |

| (5) Heat Exchanger Using city water and/or cold glycol as cooling mediums the wort is cooled to acceptable fermentation temperature, before it goes to the fermenter. |

| (6) FermenterThe wort is pumped into this vessel and added to the previously pitched yeast and allowed to ferment (typically 3 to 7 days). The fermentation tank can be used as an aging tank or the beer can be transferred to a separate vessel for the aging period (typically 10 to 20 days). |

Contact me