Description

| Customized brewery tanks |

| Brand | DEGONG BREWERY TANKS |

| Stainless steel | SUS304 Or AISI304 |

| Volume | 10Barrels(BBL) |

| Warranty | 3 Years |

Mash tun—brewing tank

A mash tun converts the starches in crushed grains into sugars for fermenting. Most mash tuns have a false bottom and sparge arm so the sparging (or lautering) process can be performed in the same tank, thus extracting the sweet liquid called wort. Insulated Mash Tuns, which are highly recommended, help reach and maintain a consistent temperature while avoiding the potential scorching that can arise from a heat sources such a gas burners or electric elements.

Our mash tuns are available up to 30+ barrels which is ideal for craft brewers to commercial and industrial breweries, and a wide range of beverages and industries. We offer steam-jacketed, gas-fired and insulated commercial mash tuns. All mash tanks are constructed from food grade stainless steel SS304 with a 3-4 mm thickness, an interior sanitary finish with exterior side walls.

10BBL brewing system

Functionality:

Full steam jacket – For more even temperature control when step mashing (steam only)

Motor and Rakes – Even grain distribution, increased efficiencies

Automatic Plow – Makes for easier mash out and clean up

False bottom – Allows removal of filter for cleaning and maintenance

Sight level Tube – Allows for easier monitoring of sparge and volume measurements

Multiple Drains – For even flow with less stuck mashes & channeling

Sloped Drain Trough – To ensure quick and complete draining of product

Sight Glass – To monitor wort clarity

Grist Hydrator – Prefect grain to water ratio decreases dough balls and gets mash temps more accurate

Sparge Ring – Ensure even sparging throughout tank with replaceable jets in case of clogging or damage

Others:

Center Temp Probe – To monitor mash temps inside the mash

LED light – To see into unit for more thorough cleaning

Glass Manway – Can be etched with your company logo for an additional charge

Gear motor – Industry leading motor and reducer

A unit of Brewhouse system brewing wquipment

Brew Kettle—brewing tank

A brew kettle is an integral part of the brewing process. This large “cooking pot” can be used to initially boil water that will be transferred to a hot liquor tank (if the brewery utilizes one), and boil the wort once it exits the mash tun. Brew kettles operate at very high temperatures, and boil over is a concern when selecting an appropriate size.

Functionality:

Whirlpool Port – Increase clarity/flavor of finished product

Side Drain port – Ability to pull wort to minimize protein and hops in finished product

Steam Drain – Cleaner finished product

Spray Ball – For full cleaning coverage

Sight Level Tube – Measure boil volumes

Condensate Drain – Ported tubing to side of tank for drainage

Rakes;Agitator;Spent grains hatch;Sight glass for brewing tank

Steam Models for brewing tanks:

70-100mm Insulation -for improved efficiency, and reduced external surface temperatures for safety

Integrated Safety Valve Port – Port directly on steam jacket for safety valve installation

Inlet and Drain Balancing Tubes – Ports enter into distribution tube, to ensure even steam supply and even condensate draining.

Others:

Level Transducer – More accurate electronic level indicator

LED – To see into unit for more thorough cleaning

Glass Manway – Can be etched with your company logo for an additional charge

Add hops to the boiling tank brewing tank

Plate heat exchanger for cooling wort;VFD transfer pumps

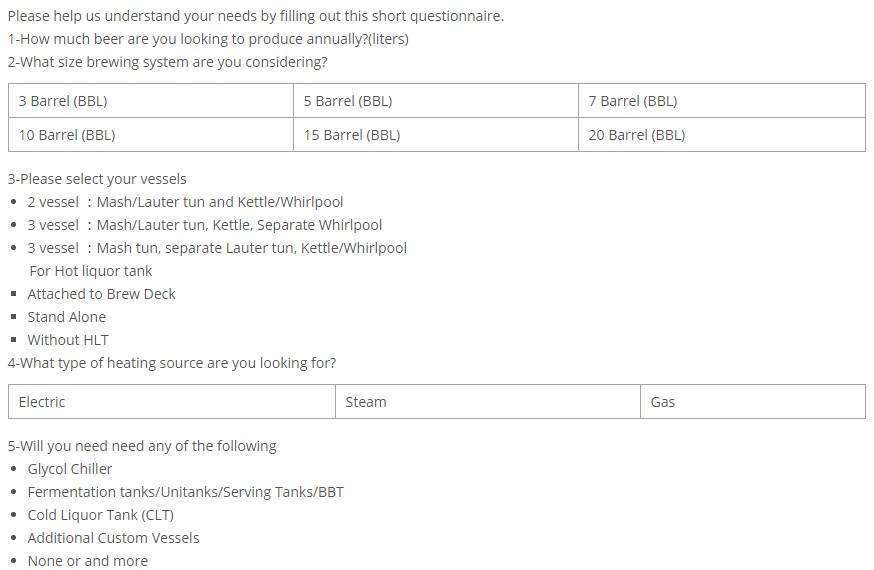

If you want to get a quotation:

| Contact Alice today |

Talk to us about your requirements and we will design a system to work for you and your company.