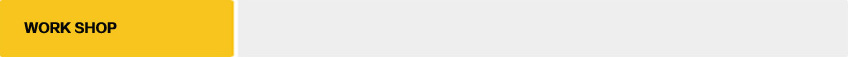

Description

3000L commercial conical fermenter manufacturers

3000L fermenter is suitable for mid size brewery.3000L fermentation tank will adopt 2-zones cooling jacket.When the tank is full of beer,you can used 2-zones to cool,it will improve cooling efficiency;When the beer level in tank is low,you can just use one cooling jacket.It will save energy.

‘

| Model | 3000L |

| Working Area | 60-100M2 |

| Working voltage | DC 24v |

| Working pressure | 1.5Bar |

| Material | Inner(SUS304),thickness: 3.0mm; |

| Insulation | Polyurethane-thickness 100 mm. |

| Temperature way | Double metal thermometer |

| Outsourcing surface: | Weld polishing processing |

| Jacket Pressure: | design pressure 0.3 MPa, working pressure <0.2 MPa. |

Size

Double wall stainless steel tank;

Gross capacity:3850L

Useful capacity:3000L

Outer :Ø1300mm; Total height: 2550

Heat exchange area:6.45㎡

1.60 or 72 degree cone bottom to drip the yeast.

2.3-sections cooling jackets. There are two sections on the cylinder and one section on the conical bottom.

3.Thd cooling medium is glycol.

- inner thickness is 3.0mm,the outer thickness is 2.0mm,the external jacket is 1.5mm.

5.The jacket design pressure is 0.3mpa,the working pressure is 0.12-0.15mpa

6.dished head,breathing valve,cleaning ball,L pipeline,pressure gauge,machanical safety valve, thermomer, sample valve, temperature,sensor, butterfly valve,pipelines, pipe surport

7.Stainless steel, vertical, double-walled, insulated, 60 degree cone bottom, dished head, beer fermentation tank.Cylindrical and conical parts have independent glycol cooling zones controlled by temperature sensor.

8.the accessories on the fermentation tank: top of the fermentation tank:breathing valve,hops hole,manhole,cleaning ball,

cylinder of the fermentation tank:L pipeline,pressure gauge,machanical safety valve,thermomer,sample valve,temperature

sensor,butterfly valve,pipelines,pipe surport

Of course all details can be customized.

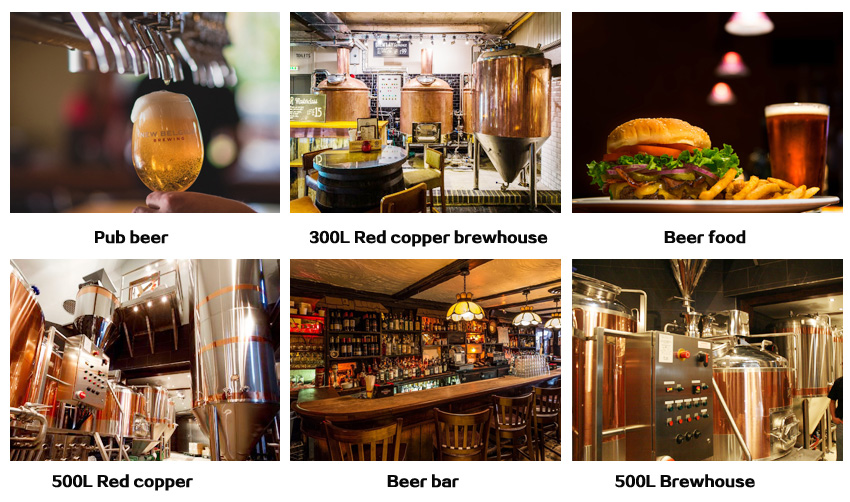

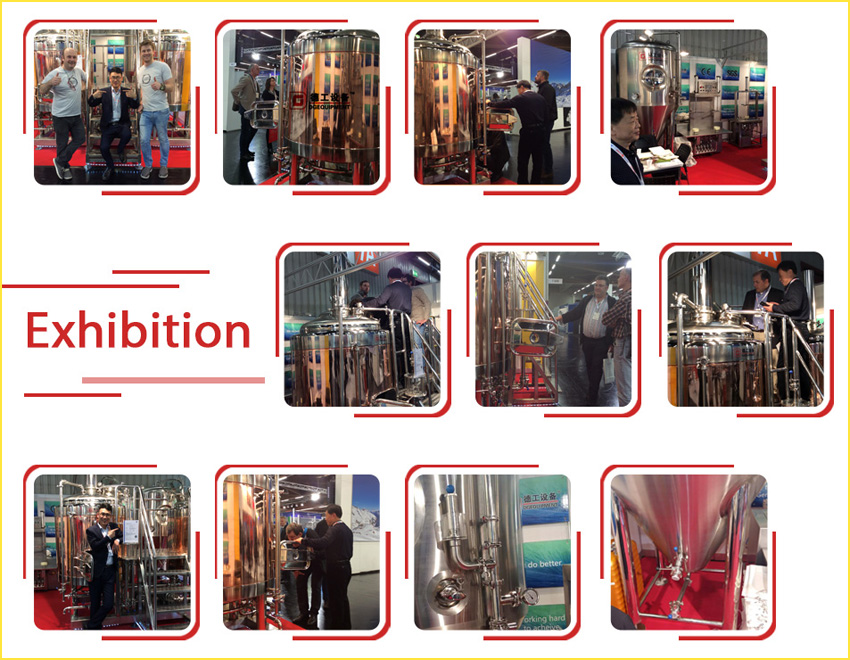

1)We can not only produce 100L,200L mini beer brewing equipment,but also produce 1000L,2000L,3000L,5000L commercial used beer brewing equipment.

2)The outsourcing material can be stainless steel or red copper.

3)All of our products with strict quality control before out of the factory. High quality raw material and accessories,double walltanks.Both sides with good quality stainless steel and well polished.

4)Customized beer brewing equipment,you can tell me your specific requirements,and we will design the equipment according to your needs,

5)The control system can be semi-auto control system and full-auto control system.The semi-auto control system,you just need to open and close the valves.