Description

| Customized brewery beer tanks |

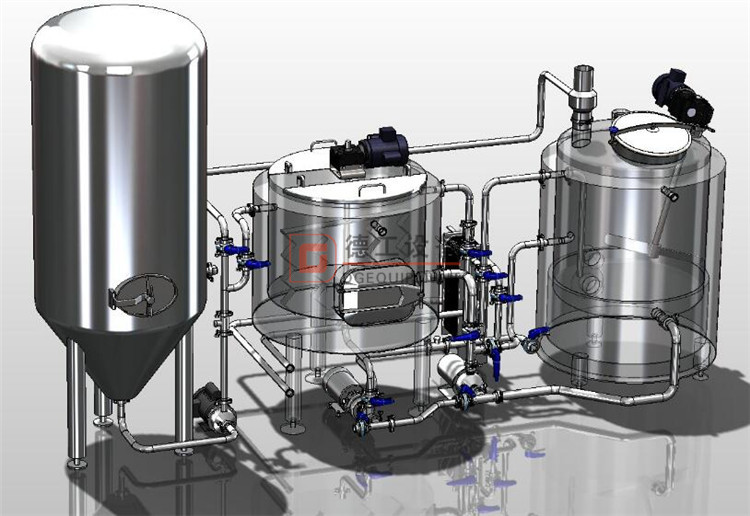

Choice of 2-, 3-, 4- and 5-vessel brewhouse configuration as well as customized vessel combinations

Brewhouse includes Mash Tun Kettle, Lauter Tun, Wort Kettle, Whirlpool;Mash/Lauter Tun, and Kettle/Whirlpool.

Introduction

5BBL Brewpub beer brewing system produced by us is a set of technological equipment for the production of “live” and filtered beer.Brewmaster make their beer attractive to consumers by unique brewing process and distinctive beer taste. If desired, they can be placed directly in places of consumption of beer: restaurants, pub, bars, hotels, tourist and shopping centers.

Also, the microbrewery is placed behind a glass partition that allows visitors to observe the process of making beer. This is an excellent design solution interior and a powerful marketig tool。Most installation in restaurants, bars and hotels used microbrewery with a capacity from 3bbl to 20BBL. Restaurants uses equipment with higher capacity. Turn-key Microbreweries can be installing at the customer’s locality .

Brewhouse system Brewery (according to client’s requirements)

Specifications

| Output/Brew | 5BBL |

| Brew/Week | 2~6 |

| Output/Week | 10BBL- 30BBL |

| Electric Supply | 3phase/380(220, 230…)v/50 (60)H

Single Phase/ 220(110, 240…)v/50(60)Hzz |

| Heating Source | Electric/Steam (OR direct fire) |

| Area Request | >50M2 |

| Brewmaster | 1 |

| Note: 1HL=100liter; 1Gallon=3.7854liter; 1Barrel (BBL) =117Liter; | |

Key benefits of brewhouse

- Pre-assembled modules offer fast installation and set-up

- Easy to expand with adding additional vessels for high throughput processing

- Eco-friendly wort production with low evaporation rates

- Highly efficient: up to 98% extract yield in the lauter tun

- Compatible with infusion and decoction mashing

Our customers’ needs have given us many opportunities to innovate and build fermentation vessels in a wide range of shapes and sizes. Unique cellar challenges are our specialty.

We have shop-built and custom designed tanks up to 100 BBLs and have the capacity to go even bigger.

DEGONG also offers a line of standard fermenters combining the best features from our custom designs with our hallmark quality craftsmanship. Our standard line tanks range from 3BBLs to 100 BBLs in size.

Brewery fermenters/unitanks/fermentation tank

| A. Beer Fermentation Tank | 1-Cylindrically-Conical Tanks, SUS 304 material conical cylindrical tank with insulation.

2-Dimple cooling jacket for ice water or glycol. 3-Pickled and passivated for inner surface. 4-Top or side manway, shadowless. 5-Dry hopping and release valve on the top. 6-Pressure gauge, sample valve, temperature sensor, spray ball, thermometer, racking arm. |

| B. Beer Conditioning Tank | 1-Serving tank, filling tank, service tank, storage tank, BBT – Bright beer tank.

2-Dimple cooling jacket for ice water or glycol. 3-Pickled and passivated for inner surface. 4-Side manway, shadowless. 5-Cabonation stone, level gauge for beer storage. 6-Pressure gauge, sample valve, temperature sensor, spray ball, thermometer. 7-Horizontal type are available. |

Compact and easy to ship, DEGONG complies with highest safety standards. Integrated systems monitor the differential pressure and provide full control of the lautering process.

Brewhouse apply to restaurant,brewpub,hotel,brew club and more

| Contact Alice today |

Talk to us about your requirements and we will design a system to work for you and your company.