Description

Breweries have classic packaging arrange consisting of brewing kettle,fermentation vessels and additional equipment.The brewery equipped with semiautomatic control panel.Staff training occurs during installation of equipment and test brews.

500L Brewery Specifications |

Our standard 500L brewhouse offering is a partially skid mounted system that includes a 500l steam fired brew kettle/whirlpool, pre-piped in our shop. The brew kettle is matched up with a 500l mash/lauter tun and 1000l hot liquor tank, allowing the brewer to make double batches in a day to increase production. This smaller yield brewhouse is perfect for smaller sized batches, special offerings, or seasonal beers.

Mash Tun / Lauter Tank

Brew Kettle / Whirlpool

Stainless Steel Work Platform with Handrails

1000L HLT

Fully Welded Sanitary Process Piping System

Complete Electrical Package

500L brewery brewhouse

Mash Tun/Lauter Tank Assembly

All stainless steel 304 construction, dished top and bottom.

Fully TIG welded assembly. Internal welds are smoothed with external welds acid cleaned and re-grained. External welds are stripe buffed.

Internal mash grid assembly withwedge wire removable screens for ease of cleaning.

(1) Sealed access door.

(2) Sealed top man door access.

(3) Thermo-well installed with RTD for measuring temperature in Mash / Lauter Tun

(4) Fully welded steam jacket with rear exit protruding steam/condensate nipples on main body.

Leg assembly with standard anchor pads.

Polyurethane insulation with gauge polished stainless steel outer shell.

Brew Kettle/ Whirlpool Assembly:

All stainless steel T-304 construction, dished top and bottom.

(1) Sealed top man door access.

Leg assembly with standard anchor pads.

Polyurethane insulation with gauge polished stainless steel outer shell.

(2) Steam flue slip flange with condensation gutter and drain port.

Fully TIG welded assembly. Internal welds are smoothed with external welds acid cleaned and re-grained. External welds are stripe buffed.

(3) Fully welded steam jackets with rear exit protruding steam/condensate nipples. Two jackets are installed on the side circumference of the tank and one is installed on the bottom dish.

(4) Thermowell installed with RTD for measuring temperature in Brew Kettle.

Dish head,transfer pump,false bottom and spent grains door

1000L Hot Liquor Tank Assembly

Dished top and bottom jacket.

(1) Fully welded steam jackets with rear protruding steam/condensate nipples.

Fully TIG welded assembly. Internal welds are smoothed with external welds acid cleaned and re-grained. External welds are stripe buffed.

(1) Sealed top man door access.

(1) Thermo-well installed for your supplied temperature probe.

Leg assembly with standard anchor pads.

Polyurethane insulation with gauge polished stainless steel outer shell.

The HLT includes an electrically actuated steam valve that is pre-wired into our control panel for temperature control.

Hot liquor tank pump as a 220/380V 3 phase motor with all stainless steel recirculation piping installed to ensure consistent strike water temperatures.

Raker and top manway

Sanitary Piping System

(1) Stainless steel work platform with handrails.

(2) Fully welded sanitary process piping package including:

All Sanitary Gaskets

Butterfly Valves

Site Glasses

Tri Clamps

(3) Transfer pump.

220V/380V 3 phase motor.

Pump mounted to the bottom of the access platform and complete with all piping connections.

(4) Dual stage all stainless-steel Mueller heat exchanger assembly mounted to the underside of the access platform. We do offer a single/double stage heat exchanger with our systems dependent of your specific needs.

(5) Grant/ Hop Back kettle complete with:

Built in float switches.

Removable wedge wire bottom screen with lift out handle.

Control cabinet (brewhouse and fermenting)

Standard Control/Electrical package will include:

Stainless steel wash down electrical box to include:

Temperature readout for the Mash Tun, Brew Kettle & HLT.

Automated temperature control for the HLT.

VFD for main transfer pump.

Float switch controllers for the Grant/Hop back kettle.

VFD for the Hot Liquor Tank pump.

On/Off/Auto switch for the Transfer pump assembly.

Wiring diagram for operation of this system

Heating options of mash tun/brew kettle: (500L brewery)

1. Steam heating

2. Natural gas heating

3. Electric heating (electric heater is placed in stainless steel cylinder)

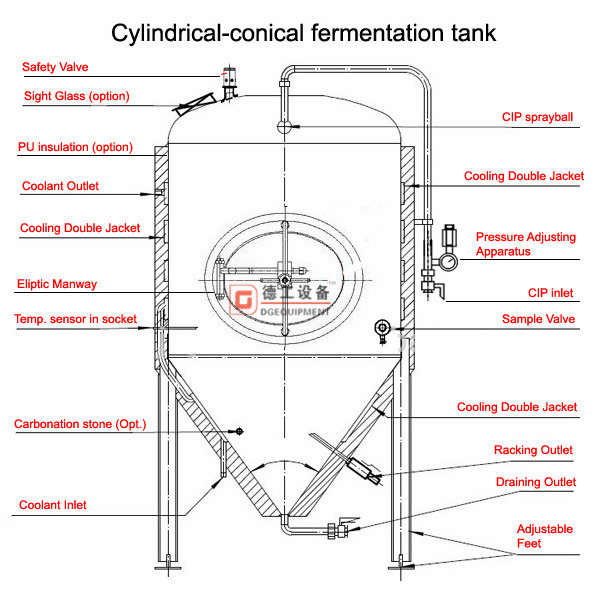

Jacketed & Insulated 4 1000 liters Fermentation tanks

Jacketed & Insulated Fermenter Assembly

· greater than 25% headspace

· cylindro-conical design

· multi-zone glycol dimpled cooling jackets

· slotted, rotary spray-ball CIP w/ 360° coverage

· CO2 blow-off arm

· hop dosing port, w/ easy-access ladder hooks

· rotating racking arm, w/ DIN fitting & easy-grip handle

· Sanitary thermowell

· optional spring-loaded RTD

· sample port with perlik style valve

· pressure / vacuum relief valve (“PRV”)

· all butterfly valves included

· SUS 304 stainless steel, TIG weld construction

· reinforced stainless steel legs, w/ leveling foot pads

· pressure-rated shadowless manway

Brewery equipment at the bar

| DGET brief introduction: |

DEGONG is a large manufacturer of beer brewing equipment, which the headquarter is located in China. Dedicate to beer equipment, beer fermentation equipment, beer bottling machine, beer keg filling machine, beer filter machine, wine production equipment, wine fermentation tank, pasteurizing equipment, water treatment equipment, steam boiler and so on. Provide the total solution to customer from designing, consulting, product to project implementation.

Equipment Design and Coordination

DGET will size the boiler and chiller system to ensure they match each individual brewery layout. Piping schematics will be developed for construction by DGET or local contractors. We can also assist the architect and building engineering team with calculations and documentation during the permitting phase of construction.

Installation, Commissioning, Startup

DGET can be involved as much as needed in the installation process of the brewing equipment. A full crew can be on site to perform the full installation or a representative can be on site to oversee a local crew. After installation of the brewing system, DGET can be on site to provide start-up assistance of all the equipment and walk the brewers through the complete brewing process with a water boil. If needed, we would even be happy to assist with the initial batches of beer produced on your new system.

| Packaging & Delivery |

Packaging Details: standard wooden package

Package Type : As usual, we adopt wooden case as package type. It’s suitable for long-distance transport. According to customers’ special demand, we could adopt sheet iron case and so on.

Loading cargo

| Contact information: |

DGET-brewing equipment for launching your own facility or private brewery for selling beer in selling points.

Warmly welcome your visit, please contact me quickly for more brewery equipment information.