Description

Normally, our 500L SS304 brewery equipment are mainly installed in small breweries,restaurants, pub, bars, hotels, tourist and shopping centers etc. With the society development, more and more people are interested in craft beer. And nothing brews delicious beer better than Grain beer brewing equipment.Our brewhouse is the system for beer brewing from the beginning of mashing process stage until the wort is cooled then passed into fermenters. Both decoction mashing and infusion mashing can be done with our equipment.

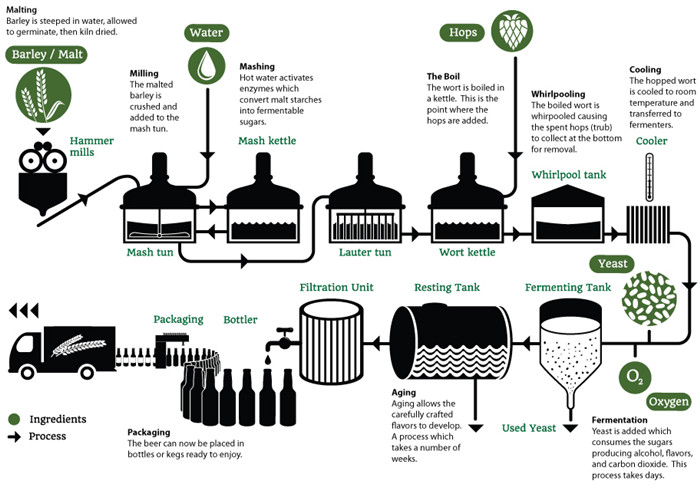

Brewing process

Barley malt→crush→mash/lauter→boiling/whirlpool→plate heat exchange→fermentation→filter→bright beer tank→beer column→drinking

Product characters

- Mash / lauter tun – grist hydrator, false bottom, rake, sparging

- Kettle / whirlpool tun – steam/ electric/ direct gas fired heating system, tangential entry

- Pumps with ABB motor

- integrated stainless steel 304 working platform

- Plate heat exchanger – SS304 or SS316 plates

- wort grant, hops back

- Pipelines and valves

- Hot liquor tanks and pumps

- 8-12 fermentation tanks/bright tanks

- Maitreya plate cooling plate

- Chiller and Glycol tanks

- CIP system

- Control box and UL/CSA/CE Rated Controls and Components

- Complete engineering support and onsite installation

Additional system

Mill: Malt crushing equipment used disc type mill or roller mill.The size of particle can be adjusted

Cooling system: Beer production cooling system generally use the liquid ammonia refrigeration compressor unit and the refrigerant tank for the temperature reducing

Cleaning and tiltering system: CIP mobile washing disinfection system, automaticalty clean and remove residues, it can prevent microbial contamination, and avoid the influence between batches.

Control system: This system includs crushing,mash, fermentation, filtering, CIP, cooling, packaging and other auxiliary control system.

Yeast propagation system: This system can realize the zero generation of yeast to expand training, and cultivate a purebred yeast, robust.

Diatomite filtration system: Under the influence of pump pressure, the liquid id running through presoating and into the collection chamber, particles and macromoolecule can be captured in coating. Clarify liquid is collect into the chamber, through the central axis, it flow out of the container.

Product feature

1.Appearance clean and generous and the equipment is bright.

2.Good insulation effect:equipment d into two kinds of heat insulation and cold insulation, which is the best to ensure the temperature of the beer brewing process.

3.Low energy conwsumption: environmental protection, energy saving, low prower consumption.

4.The overall platform design is easy to install. The process formula is automatically controlled, and the formula can be edited, modified, and saved to provide the stability of beer brewing, and the operation is simple and convenient.

Our advantage

1. DEGT is a professional company of beer brewery equipment ,nearly 10 years of beer equipment manufacturing history ( including Production→ Inspection→ Packing & Shipping→ Installation &Training → After Sales)will do its best to meet the needs of customers in all regions.Since the establishment of the company, it has been well received by numerous customers.

2. These products enable systematic execution of milling, mashing, fermentation, filtration, filling and other related processes. Before bringing these products to market, we rigorously test on each system to ensure that each brewing system is intact.

3.We have many model, for example 50L, 100L, 200L, 300L, 500L, 1000L, 2000L, 3000L, 5000L and so on. If you have other size,our engineer will specially design the equipment for you, we have professional engineers team to service for you.

Contact us

If you have needs for craft brewing equipment, please feel free to contact us,my pleasure.

Whatapp:+86 17860525597

EMAIL:[email protected]

Contact person:Kate