Description

Brief description of 500L beer brewery system

500L Beer Brewery System is between home brew and microbrewery equipment in terms of the capacity, it is a set of technological equipment for the production of verious of craft beers. Due to its affordable cost and limited space requirement, It is really a good springboard for brewers to realize their brewing dreams by selling beer to markets. With the 500L beer brewery system, Brewmasters make their beers attractive to consumers by unique brewing process and distinctive beer favor.

Degong’s micro equipment ranges from 200L to 1000L. Such brewery equipment can be used in: restaurants, pub, bars, hotels, tourist and shopping centers. What’s more, the set of 1000L brewing equipment can also be placed behind a glass partition so that visitors are allowed to observe the processes of making beer, which is a excellent marketing strategy for selling beer and advertising your brewery.

Customers examples:

Standard configuration of 500L beer brewing equipment:

Malt miller:

- 100-200kg/h

- Doubel roller

- Nosie: 45db or so

Brewhouse system:

- 500L Mash/Lauter tun

- 500l Kettle/whirlpool tun

- Steam heating method

- 1000L hot water tank

- Tubular galss level indicator

- Tangential wort inlet

- Side mounted grain outdoor with grain chute

- Laser cutting V-wire False Bottom

- Heating exchanger: 5 square meters

- Wort pump: ABB motor, VFD control

- Wort aeration device

- Yeast adding tank: 30L

- Seamless food grade stainless steel 304 pipes

- Working platform

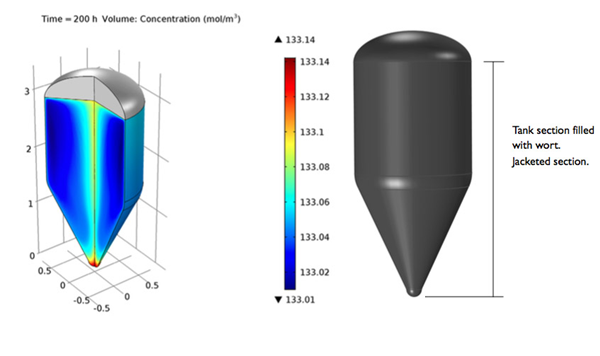

Fermentation system:

- Material Inner (SUS304) thickness: 3.0mm; Outer (SUS304) thickness: 2.0mm; External-Jacket(SUS304) thickness: 1.5mm;

- Heat exchange area:2.69 ㎡

- Equipment with : cone 60°resist compression design,dripping

- 100% TIG welding with pure argon gas shield

- Interior Finish: Sanitary 2B finish, Pickled and Passivity; (8K Mirror finish optional)

- Exterior Finish: Oil brushed finish ( 2B, 8K Mirror finish optional)

- Interior full polished to 0.2~0.4 μm without dead corner

- Insulated with high density Polyurethane foam 100mm

- Glycol Jacket: Dimpled plate on cone and side

- Stringent tank leakage test by water and pressured gas

- Stringent Jacket leakage test by water and pressured gas

- Sanitary side mounted manway with pressured door

- TC connected CIP arm with 360° coverage spraying ball

- CO2 blow-off arm with butterfly valve

- Full sanitary metallic sealed sampling valve

- Mechanical safe valve PVRV 2 bar on top

- Hydraulic shock pressure gauge on CIP arm

- Rotating racking arm and port on cone with butterfly valve

- Tri-clamp discharge arm with butterfly valve

- Thermowell for high accuracy temperature sensor

- 4 pcs completely SUS304 heavy duty legs with leveling pad and legs support

- Dry hopping port 4” TC with solid end cap

CIP system:

- 100L alkali tank with electric coils assembled inside

- 100L acid tank

- control box

- Trolley

Cooling system:

- 3HP chiller, Power: 5.25KW, Cooling capacity: 16268Kcal, Refrigerant: Freon R404A, Copeland compressor

- 500L glycol water tank

- Glycol water circulation pump, VFD control

- PPR pipes

Control system:

- Semi automatic control system or PLC fully automatic control system if requested

- Siemens/Schneider/Omron components

- PC or mobile remote control if requested

- Individual control system for brewhouse system and fermentation system

Our services:

- Beer machine maintenance

- Beer brewery installation

- Brewery tanks shipping

- Brewery equipment trainning and starting

- Design of brewery tanks

- Beer brewery production

- Customer references

- CE ISO TUV certificated

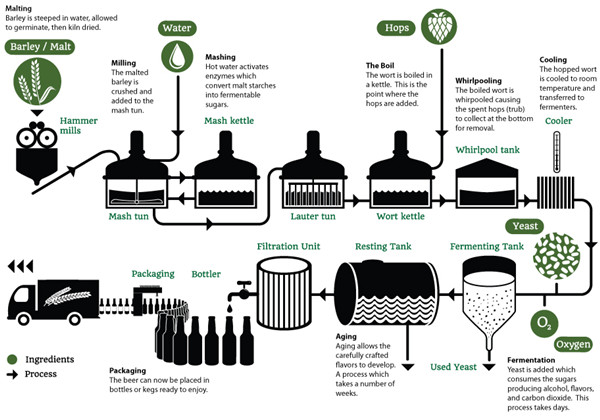

Brewing process:

Malt(Barley), water, hops and yeast are the main ingredients of beer. Even though brewing process differ slightly among different brewing techniques, but the brewing principle is same.

Contact us: