Description

DEGONG can design and manufacture beer micro brewery,large beer brewery used for any type beer,such as ale,lager,IPA….All of the insulated beer brewing equipment is customized according to your requirement.If you don’t know more about beer micro brewery equipment,our engineer can give you the most professional suggestions according to your brewing plan,such as daily output or others….

The 500L micro brewery equipment includes milling, mashing system, fermentation system, cooling system, CIP and control system.Every system is indispensable and variable.In other words, the system with same size has thousands of different configurations.

Miller system:The milling system contains malt miller and flexible auger.If the equipment is bigger,it will need a flexible auger to transfer malt.

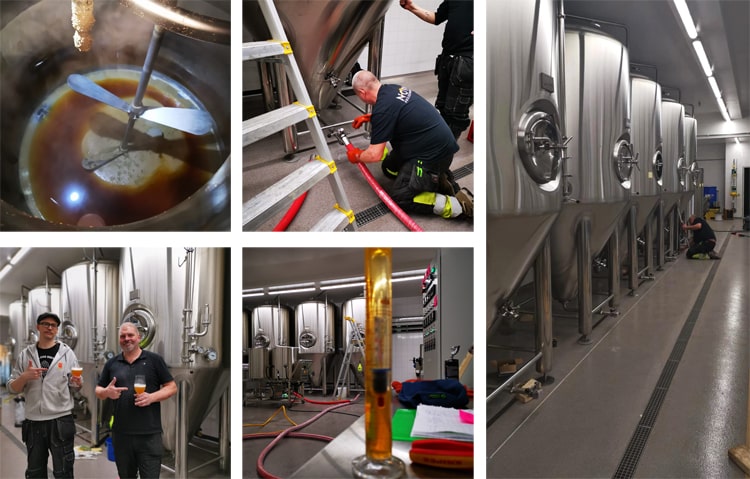

Brewhouses can be 2-vessels,3-vessels,4-vessels,with electric heating,steam heating or direct fire heating.And the material can be stainless steel and red copper.Except brewing tanks,the system also include pump,plate heat exchanger,wort grant,operation platform,hos filter and other auxiliary equipment you need.

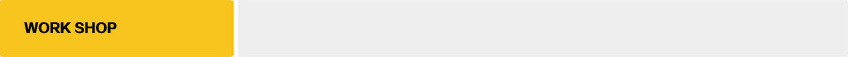

Fermentation Tanks are equipped with separate cooling zones which can be individually controlled and entirely insulated. CIP tube and a cleaning head included. The materials used and the surface finishing depend on the intended application and the customers’ specifications.

CIP system is refer to cleaning system,normally,it contains an alkali tank,a sterilization tank and a circulate pump,sometims customer also will require an acid tank.

Control system controls the whole brewing progress.All of the component is Siemens,Schenider or Omron.And it is accord with European standard.

Cooling system contains cold water tank,glycol water tank,chiller and circulate pump.The capacity of cooling system is according to quantity and capacity of fermentation tank

Brewhouse of micro brewery equipment:

- Model: 500L micro brewery equipment

- Structure: 2-vessel steam heated beer brewhouse

- Material: Stainless steel

- 304 SS TIG weld construction

- Multi-pass plate heating exchanger

- With Glass grant

- Interior mirror polishing & 2B finish exterior surface

- Design pressure: 3.0 bar Working pressure: 1.5-2 bar

- Steel manhole(Glass manhole optional)

- Platform as optional

- ABB sanitary wort pump(variable frequency pump)

- With 360 coverage spraying ball attached at the top

- With flow meter installed on the hard connecting pipes

Fermenter of micro brewery equipment:

- 304 SS TIG weld construction

- Operating pressure rated at 1.5-2 bar

- Reinforced stainless steel legs with adjustable height for leveling

- Side and bottom cooling jackets

- Tri-clover sanitary fittings

- Sample valve

- Pressure/vacuum relief valve

- Temperature gauge

- RTD sensor

- Side man way door (top manway optional)

- CIP arm and rotating spray ball 360° of coverage

- Gas arm with mechanical regulation valve

- Lifting Lugs

- Butterfly valves included

- Optional racking arm available with DIN, or tri-clover fitting

- This set of micro brewery equipment is for micro brewery, especially for pub, restaurant, hotel, etc…

- Novel structure and attractive appearance

- More competitive price and better quality

- CE, ISO, TUV approved equipment

- More humanized design which allow you to operate easily

- Compact design saving your space

- All the materials touching the beer directly are all top quality food grade stainless steel.

- We use the first rate valves and manholes for all our equipments.

- I am here to guarantee all our customers that the materials are nonmagnetic.

- The thickness of the material exactly fit in with what showed in the specification sheet.

- If you are a new comer to the beer making field, Don’t worry, I will give you our professional recommendations. And the equipment must be top quality engineered.

- Engineer is always available to make the relative 2D and 3D drawings for you for your reference.

After delivering the equipments to our customers, Degong will arrange special worker to do the track service,because we set up the marketing department for specially dealing with the feedback of customers for providing the satisfied service. Once Degong gets the feedback from customers, we will do our best to deal with it for you.

Why choose us:

1.Always delivery in time

2.Guarantee is 3 years

3.Install equipment freely

4.Real food grade SUS 304

5.Promise good pre service and after service