Description

Despite the great difference in size, however, much of the brewing process has remained essentially unchanged, as it’s dictated by relatively simple biochemical processes.

- A microbrewery, or craft beer equipment, is typically owned independently and much smaller than the corporate breweries that produce most of the beer appearing in bars and retail shelves.

- A larger brewery may use a five-vessel brewhouse, in which each of these components is a separate vessel.

500L craft beer equipment is widely used in pub, laboratory, home. The configuration is flexible depending on different working efficiency

Brewhouse combination is flexible according to your needs and daily work shift. In general, the brewhouse’s main tank: mash tun,lauter tun, kettle and whirlpool tank ,which is combined freely from two vessels to four vessels, heating method is electrical or steam heating or direct fire.

Fermenter quantity will depend on beer daily output and beer fermentation cycle.

Cooling system including glycol water tank, pump and chiller. The big cooling capacity used in heat exchanger, for cooling wort.

Control system we have 2 type, PLC control and Digital control system.

500L Beer Brewhouse include

Brewhouse usually is the combi-tank with mash/lauter,Kettle/whirlpool vessel(Hot water tank is optional)

Stainless steel work platform with sanitary process pipework and valves

Sanitary wort pump with variable speed control

Sanitary heat exchanger and wort aeration system

Tank lighting for mash-lauter and kettle/whirlpool vessels

Mash grist hydration assembly

Cellar package with brewers hoses, valves and fittings

External wort grant

Hop back

Craft beer equipment

Beer brewing system

Beer brewing system

Beer brewhouse

Craft beer equipment Features

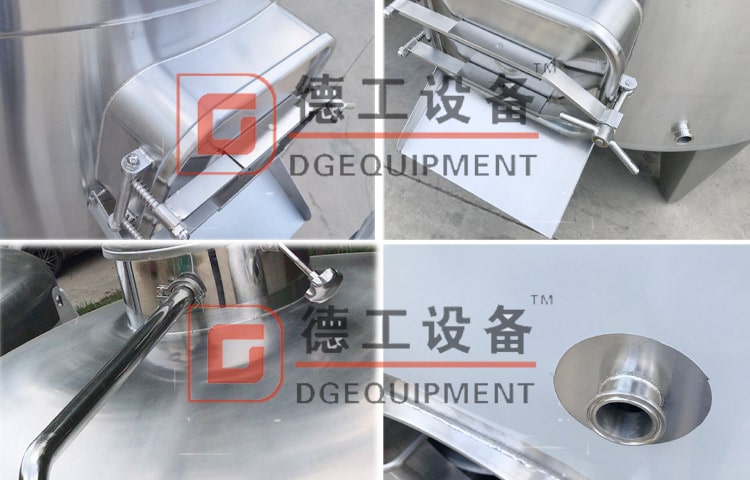

- Heavy duty 304 stainless steel construction

- Multi-piece precision wire screen

- Tri-Clamp connections for easy cleanout

- Easy access cleanout door

- Designed headspace, over 25%

- Polyurethane insulation 100mm injected

- 100% TIG welding

- VFD control pumps,motor

- Sparge ring with sprayers

Fermentation tank

Fermentation tank details

Company information

If you want to know more details,welcome to contact me.

+86 18363007358