Description

| Description of 500L stainless steel beer fermentaion tank / fermenter |

This 500L stainless steel beer fermentation tank, as one of the most important parts of a set of beer brewery equipment, which is designed and produced for the use of beer fermentation process, with glycol cooling jackets and full insulation. Brewers can acquire pressure and temperature data with the installed indicator or gauges; The specially designed top dry hopping hole is very convenient for adding and remove hops; The CIP spray ball makes cleaning job easily and completely; Beside fermentation performance, it can also be used as bright beer storage tanks by mounting a carbonation stone; It is very suitable for medium brew occasion like pubs, restaurants and hotels.

| Features of 500L stainless steel fermentation tank / fermenter |

- 100% TIG welded and sanitary polished

- Stainless steel 304 sanitary construction

- Design pressure: 3 Bar, working pressure: 0.5-2 Bar

- 4 heavy duty stainless steel legs with adjustable height and leveling pads

- Interior shell: stainless steel 304, thickness: 3mm

- Outer shell: stainless steel 304, thickness: 2mm

- Glycol water jackets: Stainless steel 304, thickness: 1.5 mm

- Interior (2B) and exterior finish bright polish, sanitary surface

- Tri-clamp sanitary fitting

- Vacuum & pressure relief valve

- Pressure gauge

- Thermometer gauge

- Sample valve

- Lifting lugs

- Ladder hooks, can also be used to hold brewing hose when not in use

- Side manhole (Top manhole as option)

- CIP arm and rotary spraing ball of 360 coverage

- Dual zone cooling jacket with glycol inlet and outlet

- Dry hopping hole

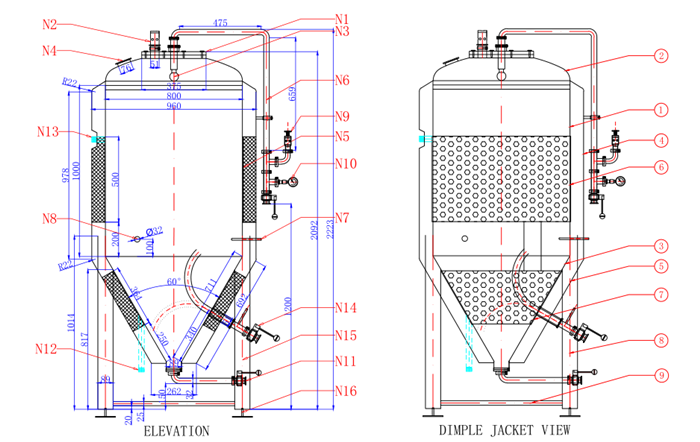

| Standard drawing of 500L stainless steel fermentation tank / fermenter |

N1: Top manhole (Flange type) N9: Pressure bunging device

N2: Vacuum & pressure relief valve N10: Pressure gauge

N3: Rotary sparging CIP ball N11: Drain

N4: Dry hopping hole N12: Glycol water inlet

N5: Glycol water jacket N13: Glycol water outlet

N6: Cleaning pipe (CIP pipe) N14: Racking arm with butterfly valve and fitting

N7:Thermowell for RTD sensor N15: Stainless steel legs

N8: Sample valve N16: Adjusting bolt with leveling foodpads

| Images of 500L stainless steel fermentation tank / fermenter |

| Services of Degong |

- Installation of 500L beer fermentation tank

- Maintennance of 500L beer fermentation tank

- Drawing providing of beer fermentation tank

- Upgrade of beer fermentation tank

- 24 hours online

| Delivery and packaging of 500L stainless steel beer fermentation tank / fermenter |

| Contact us |