Description

| 500L beer brewhouse (what are included & why is it premium) |

500L 2-vessel commercial stainless steel brewery system

Brewhouse, deemed as a beating heart of your brewing system, is vital to the quality of your beer. A weak and defective brewhouse can not work and last for long. Its main mission is to extract the useful matters like protein, sugar and get the wort ready for fermentation. How the brewhouse is structured and the used components directly affect the working efficiency. The most concerned specifications of a brewhouse are listed below. By the way, our brewhouse is custom built if you have your own specific requirements.

– Heating method: Gas / Steam / Electric for your choice. However, as to the brewhouse bigger than 500L, our recommendation is steam heating method since it’s able to heat wort more even which is good for the quality of the beer.

– Structure:2-vessel / 3-vessel / 4-vessel. According to stats, a majority of customers prefer 3-vessel structure for 1000L brewhouse, which’s good for improving working efficiency and utilization rate of resource, especially water resource.

– Wort pump: equipped with ABB motor, VFD type. Complete stainless steel and sanitary, more durable and optimal

– Wort grant: Assembled between Lauter tun and kettle, used as a wort buffer tank. The existence of wort grant can prevent grain cake from being sucked extremely tight, especially when the wort pump is not VFD type.

– Platform: We all know that the water is everywhere inside a brewery. In order to avoid getting hurt from falling down, the platform is slip-resistance designed.

– Wort aeration device: Air injection is an absolutely important process since unsterilized air could contaminate wort or even make it a tank of sour water.

– Pneumatic valve and automatic control: Utilize pneumatic valves and PLC control system to get maximum working efficiency.

– ABB / SEW / SIEMENS motor for raker: Use world renowned motor to make the brewery system not only more durable but also more optimal for brewers to operate.

– Material & Thickness: Food grade sanitary stainless steel 304. 3.0mm for inner shell, 2.0mm for outer shell and 1.5mm for dimple jacket

– Design: Compact brewhouse design, space saving and presentable

Mashing process inside the mash tun; Discharge spent grain through side manhole

Manual butterfly valves; Tempered glass for monitoring interior condition

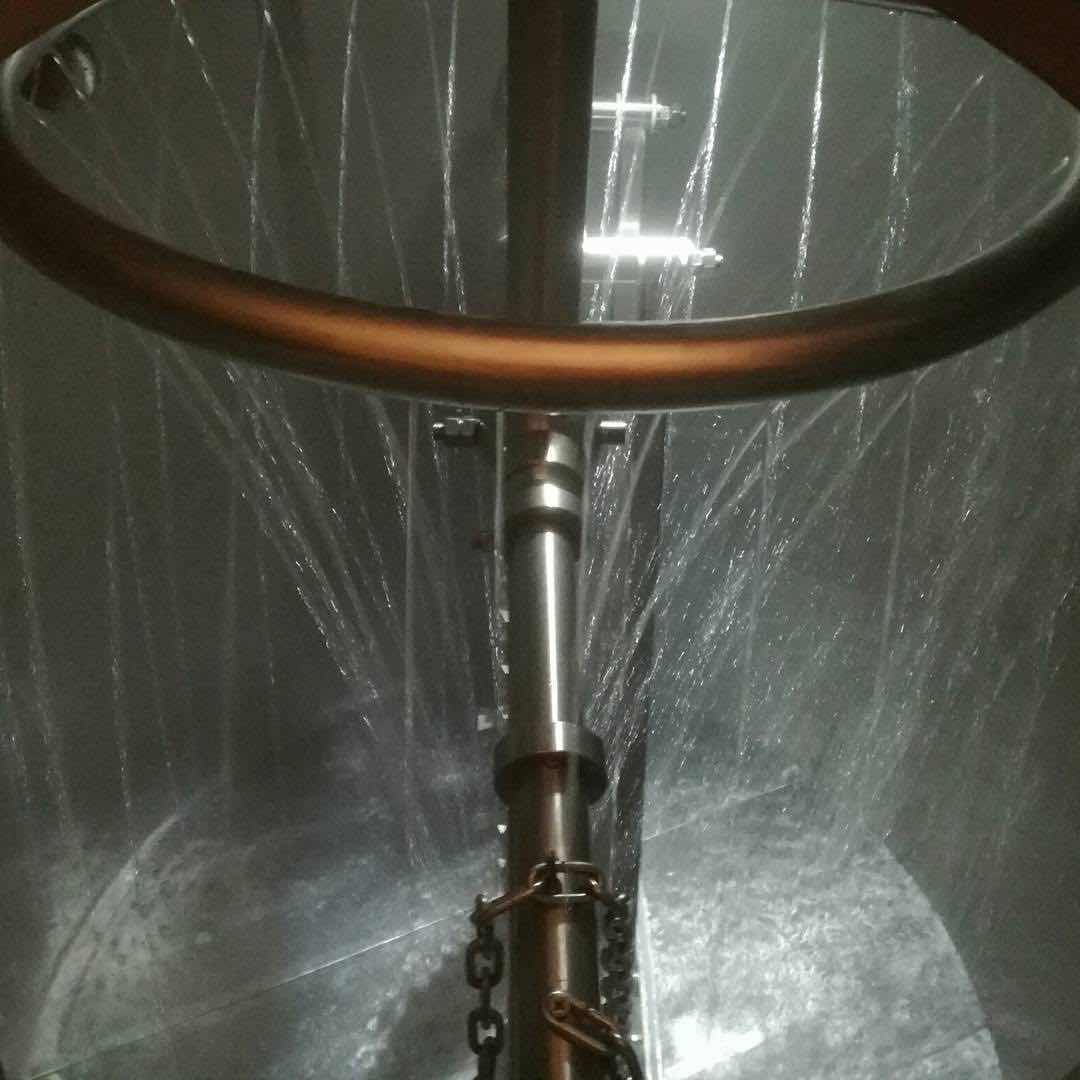

Optimal connecting pipes of the brewhouse

Grain maceration — Mash filtration — Wort boiling — Wort whirlpool – Plate heating exchanger — Yeast adding — Fermentation tank

| Specifications of 500L fermenter |

500L beer fermentation tank with top manhole

After the wort is transferred into fermenter, the fermentation process that lasts for a certain time starts. Yeasts consume oxygen to reproduce themselves at the first stage. During the second stage, alcohol and water are formed by anaerobic respiration. The beer is drinkable after the fermentation process.

– Manufacturing technique: 100% TIG welded with argon gas protection

– Material & Thickness: sanitary food grade stainless steel 304. 3.0mm for inner shell, 2.0mm for outer shell and 1.5mm for dimple jacket

– Working pressure & design pressure: 1.5-2 bar; 3 bar

– Head space: 25% of effective capacity

– Cooling method: Cooling jacket

– Interior treatment: Mirror polish

– Sample valve:

– Carbonation stone well: for oxygenating beer

– Pressure relief valve / Vacuum valve: for exhausting air when the pressure inside the tank is higher than set pressure

– Thermometer: for showing temperature visually

– Racking arm: for draining the beer out

– Pressure bunging device: for setting pressure inside the tank

– Pressure gauge: for showing the pressure inside the tank visually

– Temperature sensor: for sensing the temperature inside the fermentation tank and then submit the signal to control box via signal wire

Fermentation period of Ale is 7 days or so

Fermentation period ofLager is 14 days or so

| Beer brewing process |

| Ingredients for brewing beer |

Hops

Yeast

Barley

Water

The beer brewed in accordance with “German Beer Purity Law” can only be brewed with water, yeast, hops and malt.

| Why choose us |

Within the warranty period, any malfunctions caused by the quality issues or material issue, Degong will be responsible to it.

After delivering the equipments to our customers, Degong will arrange special worker to do the track service,because we set up the marketing department for specially dealing with the feedback of customers for providing the satisfied service. Once Degong gets the feedback from customers, we will do our best to deal with it for you.

For the malfunctions beyond the warranty period, Degong will also be responsible to it, but the seller should take in charge of the expenses.

Degong can dispatch technicians to install the equipments for you, but the seller should take charge of the expenses

3 years guarantee period

| Contact us |