Description

Beer brewing equipment details

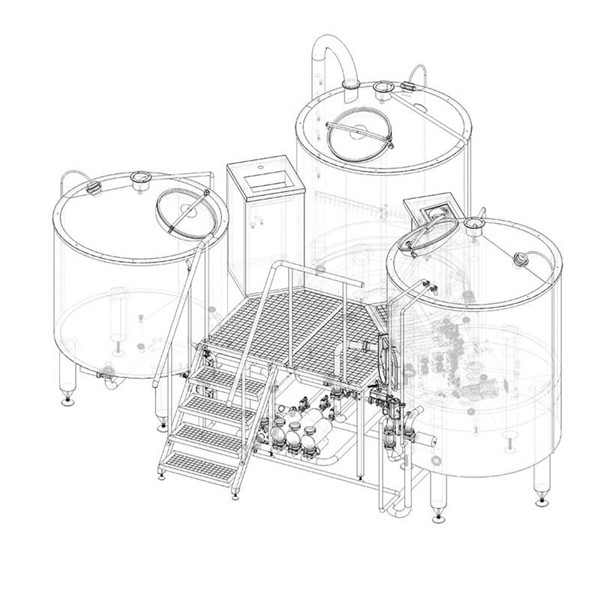

| Structure: | 500L mash tun+500L lauter tun++500L kettle tun+500 whirlpool tun+1000L hot liquor tank |

| Capacity: | 500L |

| Dimension: | Φ960x2200mm |

| Material: | Stainless steel 304 |

| Heating Way: | Steam heating/electric heating/direct fire heating |

| Electric Power: | 3 Phase,380V,50 Hz |

The brewhouse is used to get quality wort by mashing, lautering, boiling and whirlpooling etc. In the independent commercial or industrial beer plant, the brewhouse is usually customized to three even four vessel for getting a super output, 4-5 batches per day. Accordingly, the brewmasters would work in shifts to keep the brewhouse running at day and night. In order to save labor efficiently, the control system of brewhouse equipment usually be much more automatic, such as the pneumatic valve etc.

Beer brewing equipment |

Technical Parameters |

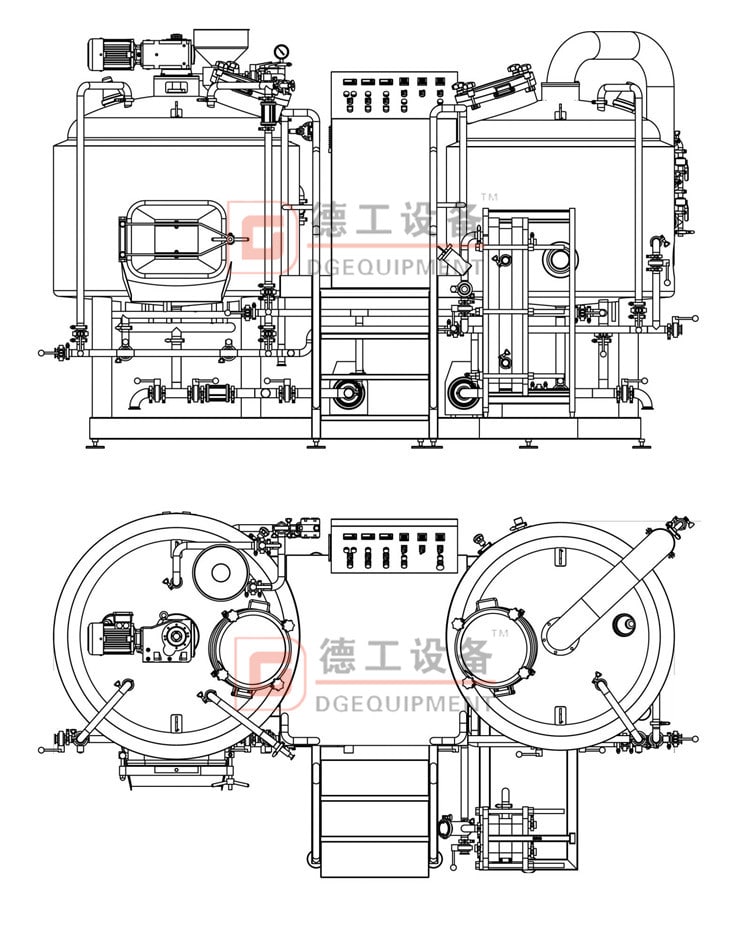

| mash tun;

lauter tun; boiling tun; whirlpool tun; hot water tank |

Material:SUS 304

1.Inner thickness:3.0mm;outer thickness:2.0mm 2.Jacket thickness:1.5mm 3.Inner surface treatment:welds grinted to Ra 0.6um 4.Mirror surface finish inside. 5.Insulation: Polyurethane-thickness 100mm 6.CIP 360 degree omni bearing cleaning 7.Outsourcing surface:weld polishing 8.Jacket pressure:design pressure:0.3Mpa,working pressure:0.12-0.15Mpa |

Application:

Our services:

- Design: DG engineers is providing various types of brewing design services according to cutomers’ requirements.

- Testing and Maintenance: professional equipment and application product testing and maintenance services according to actuall working conditions.

- Directed: transforms demand into the latest solutions and products with our advanced technology to help clients build core competitiveness.

- Project Evaluation: this assessment includes all the elements of in mind project including advantage, technology, efficiency, quality control etc.

- Continuous Service: actively provide pre-sales, sales, after-sales service and value-added services to help customers enhance value.

- Training and Improvement: carries on the thorough training to the user, in order to maximize the equipment and the product functions.

Our certificate:

As a professional brewing equipment manufacturer, we not only strictly follow the requirements of CE&ISO certification, but also to better serve our customers, we will specially customize the equipment.

Contact information: