Description

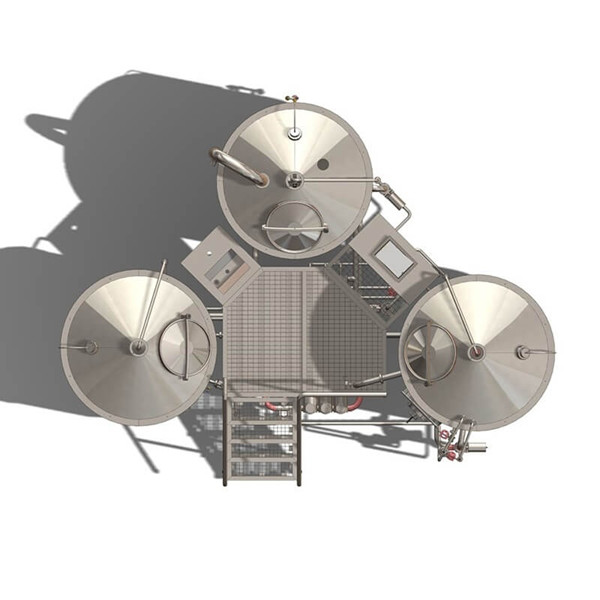

3-vessel beer brewhouse equipment

3 Vessel beer brewhouse equipment

Mash/Lauter Tun + Boil Kettle + Whirlpool Tun

Mash (kettle) Tun + Lauter Tun + Boil Kettle/Whirlpool Tun

2-vessel brewhouse equipment |

2-vessel brewhouse configuration offer brewers a simple and cost effective solution. Through combining mash tun & lauter tun, and kettle & whirlpool into a 2-vessel solution, it will help you on space and cost saving without compromising brewing quality and control. |

4-vessel brewhouse equipment |

4-vessel brewhouse configuration offer brewers a professional and higher performance brewing solution for multi batches brew per day. It is comprised by mash, lauter, kettle, whirlpool. DG’s 4-vessel brewing system offer you options of semi-auto or automation controlling and overall flexibility. |

Beer brewing process

Malt is ground in the grain mill.

The milled grains are transported with bags to mash kettle.

In the mash tun the grist is mixed with brewing water from hot water tank(to form the mash)

In the lauter tun the dissolved liquid extract (wort) is separated from the solids (spent grains)

Brewing kettle is used for boiling.

Whirlpooling is creating by circulating the wort.

The cold wort is pumped through a hose from the heat exchanger to the fermentation cellar via the brew house pump.

The wort ferments in the fermentation tank.

The green beer matures in the serving tank.

After the ageing process the beer can be served directly from this tank.

If you are interested in our beer brewhouse equipment,please feel free to contact me.