Description

We design and build complete turnkey industrial-style craft breweries toyour specifications and future expansion.We design and build a complete turnkey industrial style craft brewery to meet your specifications and future expansion. We have mature brewing technology in various large and small breweries around the world, which can ensure the reliable performance of the brewery.A complete set of SS304 beer brewing equipment is composed of six system, for example:mill system, mash system, fermentation system,control system,cooling system,cleaning system.

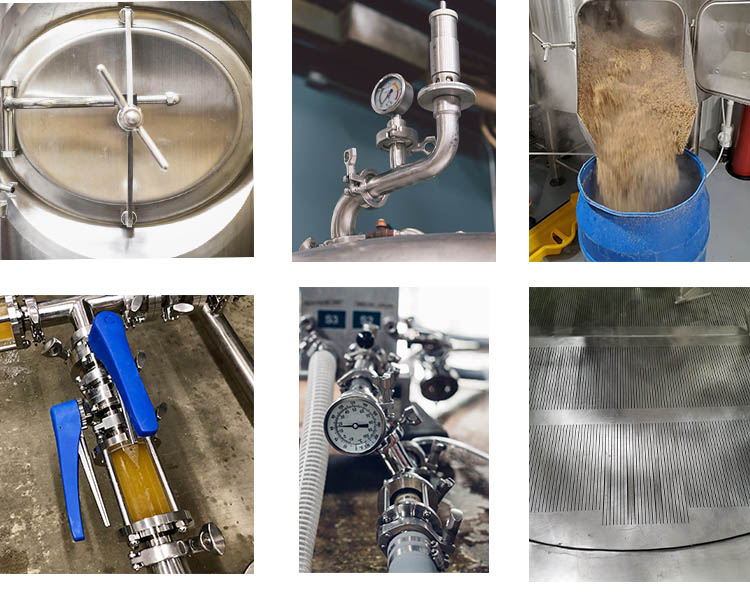

Mill system of SS304 Beer brewing equipment

The malt is pulverized by a pulverizer to a pulverization degree that can be mashed. Breaker roll type,Adjustable mill degree

Configuration of beer brewhouse(steam heating)

Mash/Lauter tun: manhole, raker, temperature probe, legs, adjustable foot etc

Kettle/Whirlpool: spary cleaning ball, stirring blades, dimpled steam jackets

Hot water tank: electric/direct fire/steam heated, high-performance polyurethane insulation

Plate heat exchange:two stages corrugated board type, wort outlet temperature is controlled.

Saccharification combination pipeline:health level SUS304 valves and piping,single welding double forming.

High quality butterfly valves

Accessories of mash system

Accessories of mash system

Configuration of fermentation system

Fermentation tank

Material inner (SUS304) thickness:3.0mm Outer(SUS304) thickness: 2.0mm

Jacket(SUS304) thickness: 1.5mm

Inner surface treament: welds grinded to 0.6μm(attached 360 degree omni cleaning ball)

High quality butterfly valves, sampile valve

Dual zone dimple cooling jackets(3 or more on larger tanks)

CIP arm and spray ball, sanitary tri-clamp connections

Bright beer tank

With an average of 20% head space, sanitary tri-clamp connections,exterior SUS304 2B finish

Material inner (SUS304) thickness:3.0mm Outer(SUS304) thickness: 2.0mm

Jacket(SUS304) thickness: 1.5mm

Superposition, horizontal stacking

High quality butterfly valves, sampile valve

Yeast adding tank

Adopts SUS304 stainless steel fine polished process, outsider stainless steel polishing, have three connestion mouths. Adding yeast sight glasses, aseptic air mouth, and wort pipe connection mouth.

Detail of fermentation system

Cleaning system SS304 Beer brewing equipment

Washing pump: SS anticorrosion pump

Alkali tank: SUS304, all welding are argon protection single-sided, double-sided forming

Sterilization tank: SUS304, all welding are argon protection single-sided, double-sided forming

Cooling system

Refrigeration unit: Axial fan motor for low noide.low power.strong wind force, original host,large cooling capacity,tight structure,convenient for package and transportation.

Beer brewing process

Beer brewing process

Mill grains→grist→grist ia mixed with brewing water(mash tun )→wort→lauter tun→kettle→adding hops→whirlpool→cooling→pitching yeast→cold wort→plate heat exchange→pump→hose→fermentation tank(primary fermentation)→adding yeast→green beer→bright beer tank→beer

Our advantage

1. DEGT is a professional company of beer brewery equipment ,nearly 10 years of beer equipment manufacturing history.( including Production→ Inspection→ Packing & Shipping→ Installation &Training → After Sales)will do its best to meet the needs of customers in all regions.Since the establishment of the company, it has been well received by numerous customers. These products enable systematic execution of milling, mashing, fermentation, filtration, filling and other related processes.

2. We tied it up with code and tied it up with a film membrane. We will choose Wooden case to protect the equipment from being damaged in transit.If the equipment’s height exceed the container’s height,and put down the equipment and fix it by iron frame.

3.Our equipment is coming with certifications of PED and our company is TUV approved. We use CE approved components for customers. The quality, specification and function all meet the treaty of contract.

Contact us

If you have needs for craft brewing equipment, please feel free to contact us,my pleasure.

Whatapp:+86 17860525597

EMAIL:[email protected]

Contact person:Kate