Description

Developed from the old traditonal German brewhouse, brewhouse is also upgrading and deriving to various brewhouse to adapt to different brewers, coutries, types and technologies, today let’s take a look two vessels beer brewhouse.The system can asssist the beer to make beer wih various flavors and different quanitity, by different process.

Configuration of two vessels beer brewhouse

Two vessels :Mash/Lauter tun & Boiling/Whirlpool tun

Capacity: 5/7/10/15/20BBL or customer mode

Configuration of the beer brewhouse

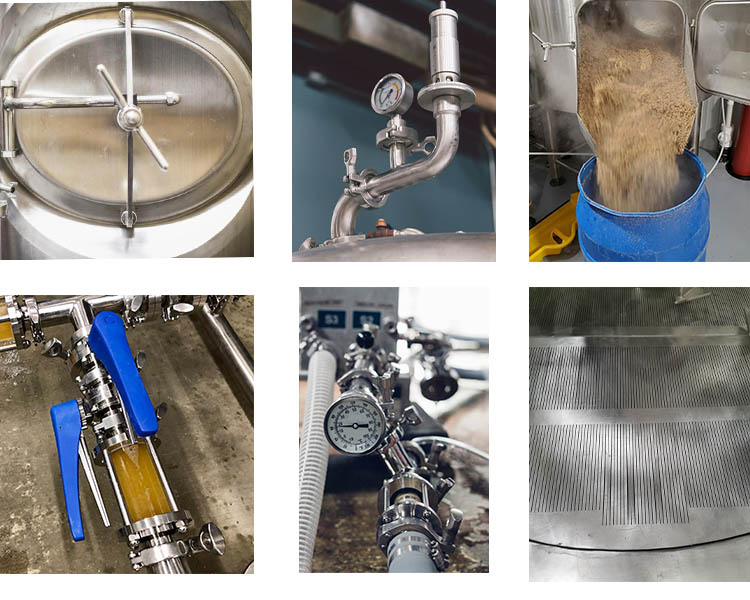

Mash/Lauter tun: Racking machine rotary tillage cutter and stir, Spent grains hatch,Top manhole

Boiling/Whirlpool tun: Bottom and top jacket, Manhole, Work platform, Piping, Pump, One or two line heat exchanger, Venturi oxygen mixture, Control box, Temperature controller, Valve.

Heating method: Steam/ Direct fire electricty heating

Other accessories: wort inlet, wort outlet, sight light, bimetallic thermometer, pressure gauge, false bottom and raker

Feature of two vessels beer brewhouse

1.The heating method of brewhouse

Electric heating: it need electric heating pipe, the advantage is that it can save costs, but some countries have higher electricity , and the cost of use is higher.Then they will choose steam heating or direct fire heating. But the disadvantage of electric heating is to occur paste pot.

Steam heating: it is most stable and efficient heating method. But it need steam boiler that need gas boiler, diesel boiler and electric bolier.

Direct fire heating: it compared with some countries, the electricity is expensive, and the steam boiler is very strict, this heating method is the most suitable.

2.The inside layer of the tank material uses SUS304/316 , the surface of the equipment can be made of red copper and high quaility stainless steel material of specular color pattern. It is of better practical and decorative. The whole equipment and the layout of pipielines look very neat. It can be operated easily and be of stable functionity.All the pipes and valves among the whole eqipments are connected by stainless steel joint for easy to connect, install, uninstall, move, and alter.

Our advantage

- DEGT is a professional company of beer brewery equipment , will do its best to meet the needs of customers in all regions.Since the establishment of the company, it has been well received by numerous customers.These products enable systematic execution of milling, mashing, fermentation, filtration, filling and other related processes. Before bringing these products to market, we rigorously test on each system to ensure that each brewing system is intact.

- The warranty period of our equipment is three years. Before we ship, we will mark the equipment, including the pipe, for the convenience of customers to assemble.

- We tied it up with code and tied it up with a film membrane and will choose Wooden case to protect the equipment from damaging in transit.If the equipment’s height exceed the container’s height,we will put down the equipment and fix it by iron frame.

- We can provide engineers to help you install the equipment, and we can also provide winemakers to help you solve technical problems.

- Our equipment is coming with certifications of PED and our company is TUV approved. We use CE approved components for customers. The quality, specification and function all meet the treaty of contract.

Contact us

If you are interested in beer equipment, or want to build your own brewery, and have your own beer brand.Please feel free to contact us Welcome to order beer equipment.My pleasure.

Whatapp:+86 17860525597

EMAIL:[email protected]

Contact person:Kate