Description

| Please tell me your needs,we can manage a perfect offer |

| 10HL Fermenters in our factory |

As one of the important steps in brewing beer, fermentation is the process of obtaining beer. Therefore, it is very important to choose a good quality fermentation tank. DEGONG is such a manufacturer to design and even customize the functions you need. Welcome to learn more about beer equipment in order to help you get satisfactory quotations and products.

Fermenting vessels in our factory are ready to sell

Specifications of 1000L/10HL :

| No. | Item | Description |

| 01 | Working Volume | 1000L/10HL |

| 02 | Dimension | 1300*2550mm |

| 03 | Material | Stainless steel 304 |

| 04 | Insulation | Polyurethane, TH:100mm |

| 05 | Fermentation tank |

Glycol jacket: Dimpled jacket on the cone and side Or single wall with jacketed,or single layer fermenter. |

| 06 | Head | Double layer dish head on the top |

| 07 | Accessories | Sample valve, pressure gauge, solenoid valve, pressure relief valve, racking arm, CIP arm and Blow off arm, dry hops port and so on. |

Fermenting vessels installed in the brewery

Glycol chillers – temperature control

Temperature control is one of the most crucial elements for producing a good quality product. It needs to be regulated and stable throughout the whole fermentation process, to ensure the yeast doesn’t get stressed and ferments correctly to get the right flavour profile. Glycol chillers facilitate temperature control.

With the ability to individually control the temperature of the fermentation while using a glycol cooler, the producer can regulate the temperature of the fermentation vessel to suit their requirements and the current ambient temperature

Pressure gauge,breather valve,side manway…on the fermenting vessels

Fermenting vessels features:

- Possibility to choose among various finishing: satinized, 2B, mirror polished;

- Constructed with at least 30% more useful volume, in order to prevent spilling of foam during the fermentation phase, and high-quality, hermetically welded Aisi 304 stainless steel coating;

- Constructed with food-grade TIG welding with Argon inert gas protection;

- Complete with insulating system at the bottom and on the shell in order to avoid temperature loss;

- Supplied with upper/side manhole and external graduated level indicator bar;

- Equipped with spray balls to guarantee complete cleaning;

- CE Certified

With every fermentation tank we produce, we carry out rigorous radio-graphic inspection on welding lines to ensure the prevention of contamination. DEGONG also utilizes state-of-the-art auto-polishing and electric-polishing technologies, which meet ASME and other international standards for in-tank sanitary requirements.

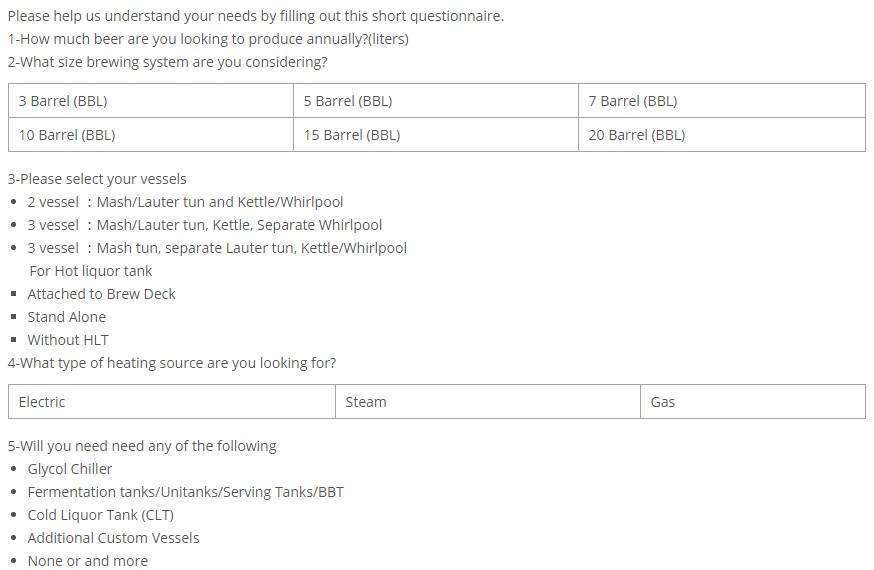

| Contact Alice today |

Talk to us about your requirements and we will design a system to work for you and your company. wlcome to consult brewery to get a perfect quotation.