Description

600L/1200L brew system includes: mill system,mash system, fermentation system, cooling system, cleaning system, control system.Whether you are a start-up, a well-established craft brewery or a market leading brand – you can benefit from DGET in the brewery industry. Our catalog of high-quality equipment ranges from complete systems to process units to components. We process first-class product technology and the most advanced processing equipment in the stainless steel manufacturing industry as well as quality inspection instrument and method suring producing.

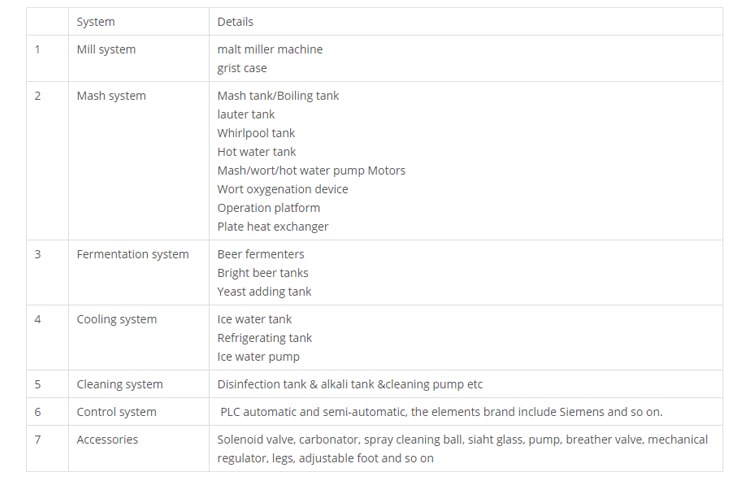

Details of brewhouse

Accessories of brew fermentation tank

Bright beer tank

Material:Inner(SUS304),thickness:3.0mm,Jacket(SUS)304,thickness:1.5mm

Outer(SUS304),thickness:2.0mm

Inner surface treatment:welds grinded to 0.6μm

Insulation:Polyurethane-thickness 100mm

Temperature way:Double matal thermometer

Outsourcing surface:Weld polishing processing

Jacket Pressure:design pressure 0.3MPa,working pressure <0.2MPa.

CIP 360 degrees Omni bearing cleaning

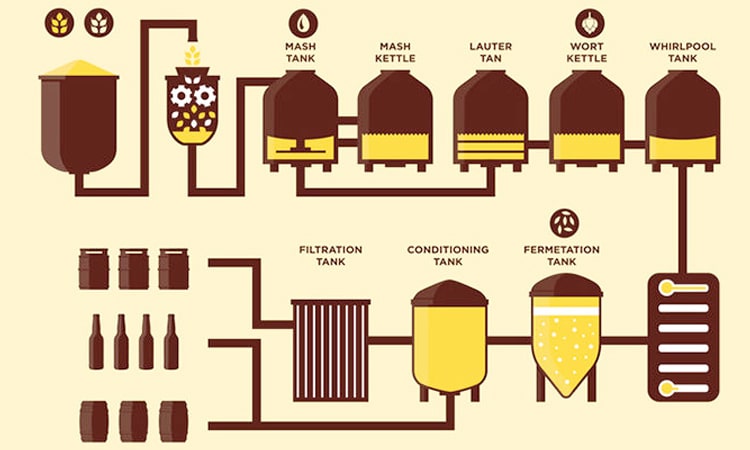

Brew system process

Mill grains→grist→grist ia mixed with brewing water(mash tun )→wort→lauter tun→kettle→adding hops→whirlpool→cooling→pitching yeast→cold wort→plate heat exchange→pump→hose→fermentation tank(primary fermentation)→adding yeast→green beer→bright beer tank→beer.

Brew system additional

Mill: Malt crushing equipment used disc type mill or roller mill.The size of particle can be adjusted

Cooling system: Beer production cooling system generally use the liquid ammonia refrigeration compressor unit and the refrigerant tank for the temperature reducing

Cleaning and tiltering system: CIP mobile washing disinfection system, automaticalty clean and remove residues, it can prevent microbial contamination, and avoid the influence between batches.

Control system: This system includs crushing,mash, fermentation, filtering, CIP, cooling, packaging and other auxiliary control system.

Yeast propagation system: This system can realize the zero generation of yeast to expand training, and cultivate a purebred yeast, robust.

Why choose us

Contact us

If you are interested in beer equipment, or want to build your own brewery, and have your own beer brand. Please feel free to contact us Welcome to order beer equipment. My pleasure.

Whatapp:+86 17860525597

EMAIL:[email protected]

Contact person:Kate