Description

Craft Fermentation tanks can be individually temperature controlled through glycol jackets. Accessories include pressure relief valve, CIP cleaning jet, sanitary sample valve, manhole,etc. The design of the DEGT fermentation tank is based on beer knowledge, especially the bottom of the conical fermentation tank. When calculating the fermentation and storage capacity and configuration, it is necessary to consider sufficient time for fermentation and storage of beer, so as to produce high-quality beer.

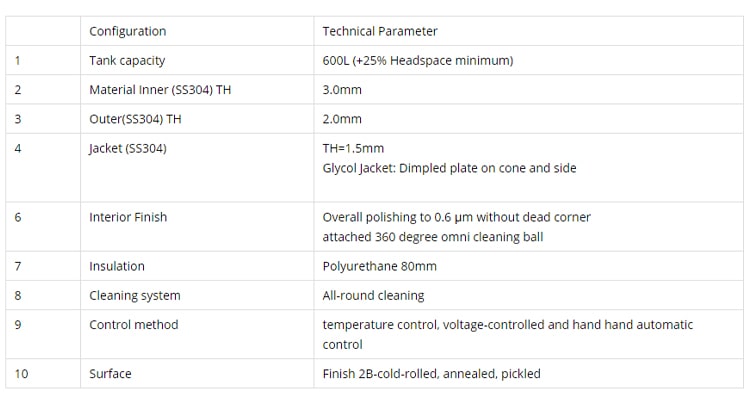

Configuration of fermentation tank

Accessories of craft fermentation tanks

Solenoid valve, temperature sensor pt100, pipe connection welding, 360° rotary spray ball, breather valve, sampling valve, mechanical regulator valve, raking arm, adjustable foot, butterfly valve and four stainless steel legs, with feet for leveling and height adjustment, base plate with two holes for fixing to the floor, with reinforcements between the legs.

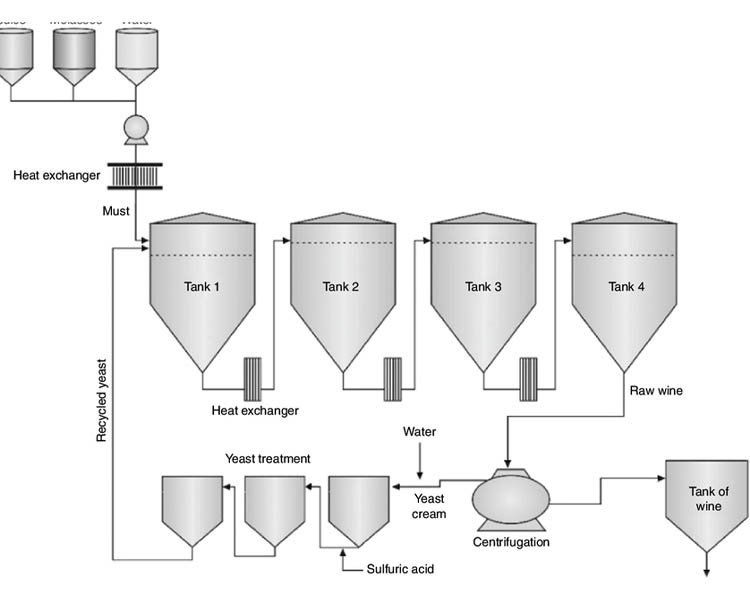

Fermentation process

The fermentation of beer is a complex process, mainly divided into two stages: aerobic respiration and anaerobic respiration. Aerobic respiration is to increase the value of yeast, and anaerobic respiration is to produce ethanol and CO₂. The main metabolites of yeast are ethanol and CO₂. The primary fermentaion(in the fermentation tank) is completed, the green beer is pumped via a transportable pump to the bright beer tank. After the ageing process the beer can be served direstly from this tank.

Feature of craft fermentation tanks

1. Appearance clean and generous and the equipment is bright;

2. Good insulation effect: the equipment is divided into two kinds of heat insulation and cold insulation, which is the best to ensure the temperature of the beer brewing process;

3. Low energy consumption: environmental protection, energy saving, low powerconsumption.

4. Stringent tank leakage test by water and pressured gas

5. Stringent Jacket leakage test by water and pressured gas

6. Rotating racking arm and port on cone with butterfly valve

7. Tri clamp discharge arm with butterfly valve

8. Thermowell for high accuracy temperature sensor

Our advantage

1. DEGT is a professional company of beer brewery equipment ,nearly 10 years of beer equipment manufacturing history( including Production→ Inspection→ Packing & Shipping→ Installation &Training → After Sales)will do its best to meet the needs of customers in all regions.Since the establishment of the company, it has been well received by numerous customers.

2. These products enable systematic execution of milling, mashing, fermentation, filtration, filling and other related processes. Bringing these products to market, after we rigorously test on each system.

3.We tied it up with code and tied it up with a film membrane. We will choose wooden case to protect the equipment from being damaged in transit. If the equipment’s height exceed the container’s height,put down the equipment and fix it by iron frame.

Contact us

If you have needs for craft brewing equipment, please feel free to contact us,my pleasure.

Whatapp:+86 17860525597

EMAIL:[email protected]

Contact person:Kate