Description

Steam Heated Beer Equipment (7 BBL Steam Fired Brewhouse) Includes

Mash Tun / Lauter Tank

Brew Kettle / Whirlpool

Hot water tank

Stainless Steel Work Platform with Handrails

Fully Welded Sanitary Process Piping System

Complete Electrical Package

7 BBL Steam Heated Brewhouse Specifications

Steam heating: The equipment is equipped with a steam jacket and a steam boiler is also provided. (Steam boiler: electric boiler, diesel boiler, gas boiler.)

Mash Tun/Lauter Tank configuration

Feature: grain mashing, lautering and sparging

inner diameter all stainless steel T-304 construction, dished top and bottom.

Fully welded assembly. Internal welds are smoothed with external welds acid cleaned and re-grained.

Insolution: Polyurethane-thickness 100mm.

Inner surfacr treatment: welds grinded to Ra 0.6μm

Jacket pressure: design pressure 0.3MPa, working pressure <0.2MPa

CIP 360 degrees Omni bearing cleaning

Four stainless steel legs, with feet for leveling and height adjustment, base plate with two holes for fixing to the floor; with reinforcements between the legs.

Kettle/Whirlpool configuration

Feature: wort boiling, hopping and whirlpool

inner diameter all stainless steel T-304 construction, dished top and bottom.

Glass top mahole

Steam condensewr with spray nozzles

Internal welds are smoothed with external welds acid cleaned and re-grained. External welds are stripe buffed.

Fully welded steam jackets with rear exit protruding steam/condensate nipples. Two jackets are installed on the side circumference of the tank and one is installed on the bottom dish.

4 pcs completely SUS304 heavy duty legs withy leveling

Hot water tank configuration

Feature: boiling water

TIG welding with pure argon gas shield

Glass top manhole

Temperature way: Double metal thermometer

Thermo well for high accuracy temeprature sensor

4 pcs completely SUS304 heavy duty legs withy leveling

Wort pump / hot watre pump

Capacity: 3000L/h, stainless steel 304 food deliver pump. Power: 0.75KW.

The use of advanced inverter control of motors, energy-saving mute. The motor speed can be controlle and adjusted by transducer.

Brewhouse Accessories

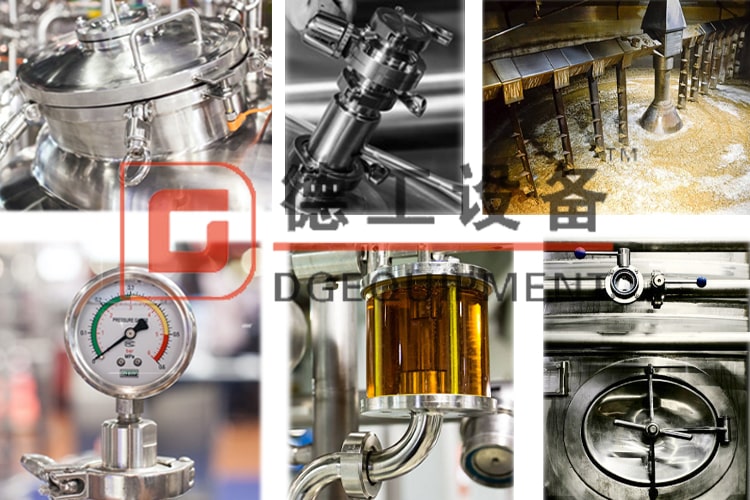

Brewhouse details

Steam Heated Beer Equipment(fermentation system)Specifications

Fermentation tank configuration

Oval head cone bottom, cone 60° resist compression design, dripping

TIG welding wit pure argon gas shield

Glycol Jacket: Dimpled plate on cone and side

Stringent tank leakage test by water and pressured gas

Stringent Jacket leakage test by water and pressured gas

Full sanitary metallic sealed sampling valve

Hydraulic shock pressure gauge on CIP arm

Rotating racking arm and port on cone with butterfly valve

Pressure gauge, thermometer gauge, sample valve dry hop port

A row of fermentation tanks

7BBL fermentation tank details

Additional system

Mill system: Malt crushing equipment used disc type mill or roller mill.The size of particle can be adjusted

Cooling system: Beer production cooling system generally use the liquid ammonia refrigeration compressor unit, the refrigerant tank for the temperature reducing.

Mill system

Cooling system

If you want to build dream brewery, please contact me freely.