Description

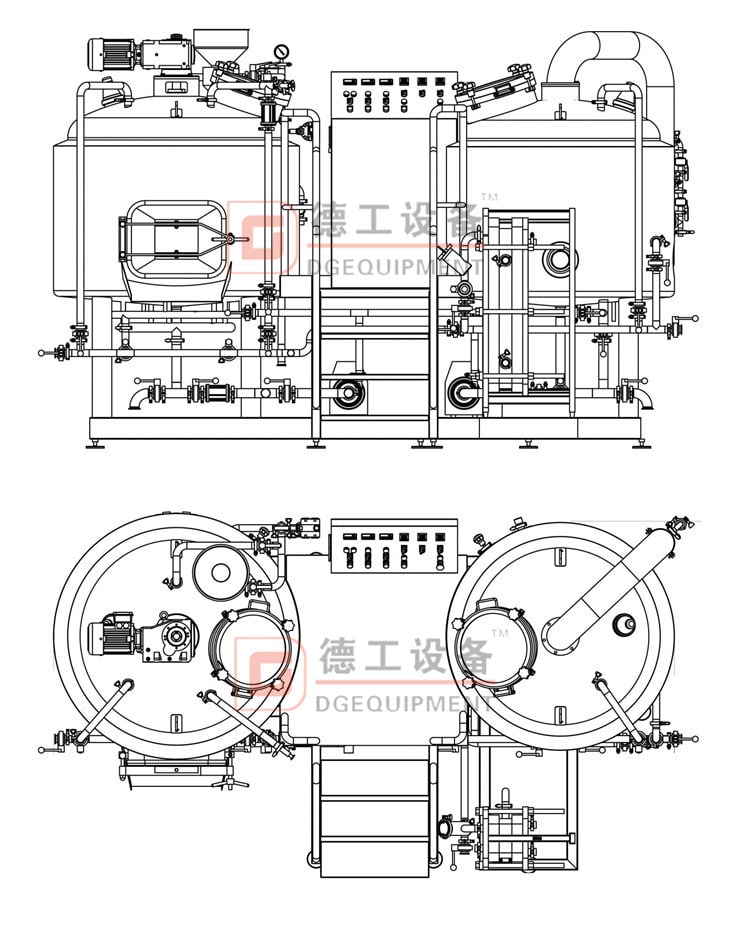

2 vessel brewhouse system for sale

2 vessel brewhouse system for sale

Free combination according to customer needs

Brew assembly adopted with three vessels: Mash Brew Kettle, Lauter tun and Whirpool tun.

The vessels are separated in order to maximize system efficiency and adopted with working platform to provide productive conditions for operating personal.

Brew kettle assembled with mash agitator, boiling channels and has whirpooling functions. Lauter tun assembled with rakers and screen plate for grains separation.Whirpool tun is multi-functioned for wort whirpooling, water heating and hot water storing.

Two stage heat exchanger used for wort cooling by cold water and meanwhile heating the tap water for next brewing or for system sanitation process that provides an energy savings.It also assembled with two sanitary frequency controlled pumps ,providing a low transfer speed for filtration and sparging and high transfer speed for intensive and effective system cleaning.Pipeline provides multiple wort transfers providing multiple brewing process methods and sanitary performance.

Mash Lauter tun (brewhouse system)

Use – mashing, mixing and wort boiling.

Position – vertical

Appearance – Cylindric, top domed with conical inner bottom.

-Material body sus304

-Insulation- polyurethane 100 mm

-Cylindric and bottom milled steam heating – Max 3 bar pressure ensures 1°C/min heating speed.

-Complete pre-piped, pre-wired and test run prior to shipment.

Assembly:

-Top domed thermostatic hermetic closed glass manway door.

-Stainless steel mixer activated by 1.5 kw geardrive motor SIEMENS.

-Top domed lighted sight glass.

-Quick installed termo sensor PT100 connected to multi segments programmable controller

-Quick installed modular steam outlet condensator assembled with 0.5kw centrifugal water recycling pump for energy and water saving.

-Top domed cylindric hops grant for online hops insertion, adopted with wort circulation for effective mixing.

– Sanitary centrifugal 2.2 kw mash pump with VDF controller.

– Bottom mash inlet /outlet.

– Middle side wort/water inlet/outlet.

– Top dome wort /water inlet.

– Middle cone wort outlet.

– Quick installed Spray CIP balls X2 .

– Outlet/darainage connections –DN40

– Inlet connections –DN32

Modular 4 parts screen sieve separating the wort bath from lautering area.

Sieve flutes width- 1 mm.

Sieve loading – 120-160 kg/ m2

Brewhouse detail platform top, manhole…

Brewhouse system Assembly:

-Top domed thermostatic hermetic closed glass manway door.

-Stainless steel raker activated by 1.7kw geardrive motor SIEMENS.

-Top domed lighted sight glass.

-Quick installed termo sensor PT100 connected to controller for temperature measurement output.

– Rectangle sieve level placed hermetic closed manway door used for manual grains draining and sanitation operating.

– Sanitary centrifugal filtering 2.2 kw pump SIEMENS with VDF controller ensures controlled filtration and wort pellucid processes.

– Transflusient filtration cylindricwort grant contains: wort inlet with wort inspection valve, wort outlet, CIP ball for sanitation, gravity balancing valve for effective gravity and pump filtration.

-Wort sprinkling provided by sparging semicircle or spray balls.

-1 bar pressure release/vacumm valve placed on the dome for pressure discharging during aggressive sanitation process while the tank is hermetically closed for operation personal safety.

– Bottom wort outlet.

– Middle side wort/grains outlet for decoction process (if needed) and water inlet for stuck lautering preventing.

– Top dome wort /water inlet.

– Quick installed Spray CIP balls X2

-Lautertun piping connections are assembled for providing both gravity and pumping filtration, continuous and batch sparging.

– Outlet/drainage connections –DN40

– Inlet connections –DN32

Kettle Whirpool Combi vessel(brewhouse system)

Use – wortwhirpooling, hot water preparation.

Position – vertical

Appearance – Cylindric, top domed with conical inner bottom.

-Material body and insulation cladding- sus304

-Insulation- polyurethane 100 mm

-Cylindric and bottom milled steam heating – Max 3 bar pressure ensures 1°C/min heating speed.

-Complete pre-piped, pre-wired and test run prior to shipment.

Assembly:

-Top domed thermostatic hermetic closedglassmanway door.

-Top domed lighted sight glass.

-Sanitary food grade thermo resistant silicone level gauge.

-1Bar pressure release/vacumm valve placed on the dome for pressure discharging during aggressive sanitation process while the tank is hermetically closed for operation personal safety.

-Quick installed termo sensor PT100 connected to multi segments programmable controller

– Bottom cone inlet /outlet.

– Middle cone clear wort outlet.

– Middle side wort/water inlet/outlet.

– Top dome wort /water inlet.

– Quick installed Spray CIP balls X2 .

– Outlet/darainage connections –DN40

– Inlet connections –DN32

Contact us

If you are interested in our beer equipment,please feel free to contact me.