Description

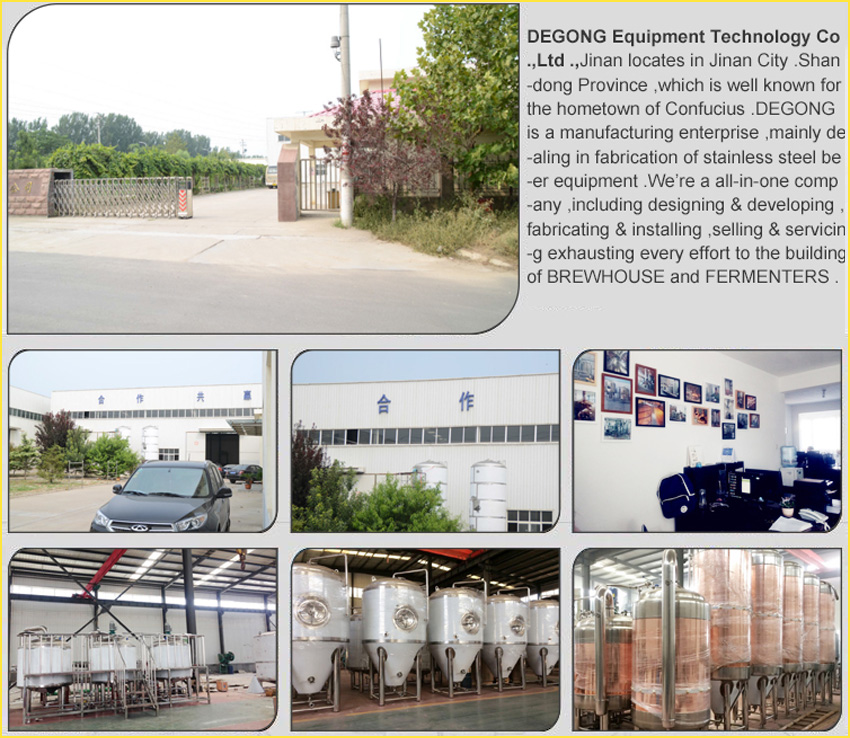

1.Specialist manufacturer

We have own factory. We get CE certification.We specialize in manufacturing beer brewing equipment.

2.Quality and price

We have professional purchasing team. Comparing multiple vendors,choose

best raw materials and the most preferential price. We have skilled worker and

strict quality control system,provide the best quality products to our customers.

3.Convenient transportation

Our company is located in Jinan,which is near Qingdao port It just take 3 hours from our factory

5.Quality of service

We will provide photos make our customers to know the order status.Of course,we welcome our customers to our factory to inspect any time!

7BBl Bar beer brewing equipment

| Model | 7BBl Bar beer brewing equipment |

| Working Area | 2-30M2 |

| Working voltage | DC 24v |

| Working pressure | 1.5Bar |

| Material | Inner(SUS304),thickness: 3.0mm; |

| Insulation | Polyurethane-thickness 100 mm. |

| Temperature way | Double metal thermometer |

| Outsourcing surface: | Weld polishing processing |

| Jacket Pressure: | design pressure 0.3 MPa, working pressure <0.2 MPa. |

1. This beer equipment machine is brewery for pub ,Bar,Restaurant draft .

2. Stable worktable and 20 years usage life.

3. Easy to maintain saving time and labor.

4. This machine is economy and competitive.

Configuration:

1.Malt Milling Unit

Particle adjustable rolling crusher for dry or wet milling

Flexible or steel auger or a bucket type conveyor to directly lift the milled grain to mash tun

2.5000L Brewhouse Unit

Mash tun, Lauter tun, Boiling Kettle, Whirlpool tun in various combination

Hot water tank and cold water tank for optional in special combinations

Infusion or decoction brewing methods are designed exactly

Stainless steel cladding is even the unique because of easy maintenance and clean

Two stages or single stage heat exchanger for wort cooling

Completely stainless steel integrated work platform

Sanitary and efficiency wort pump

All pipings, pipes maniford and fittings

3.5000L or 10000L Fermentation Unit

Standard stainless steel conical cylindrical fermentation tanks

Single, double, triple or more size as brewhouse is common used in commercial breweries

Tanks quantity is exactly calculated by fermentation cycle for various beers

Roof walkway is for special request

All manhole, valves, pressure gauges, fittings etc are included

4.Beer Filter Unit

Large plate-Frame or Candle type DE (diatomite earth) filter is used for clarify the beer

5.5000L or 10000L Bright Beer Tank Unit

Standard stainless steel bright tanks for beer maturation, conditioning, service, carbonation

Single,double size or more as fermenter is common used

Tanks quantity is exactly calculated for various beers and the function

All manhole, valves, stone, gauges, fittings etc are included

6.Cooling Unit

Insulated glycol water tank with or without copper coil for glycol liquid holding and mixing

Efficiency chillers or refrigerators with fryon to supply cooling energy

Sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger

All pipes, fitting, insulation materials are included

7.Controlling Unit

Electrical controlling cabinet with temperature, on-off controlling for brewhouse

Electrical controlling cabinet with temperature, on-off controlling for cooling parts

Temperature controller, thermocouple, solenoid valves etc are included

PLC with touch screen panel for special request

8.Beer Dispense

Semiauto or automatic bottling machine with rinsing, filling, capping, labeling etc

Semiauto or automatic canning machine

Flash pasteurizer or tunnel pasteurizer is available

9.Other Facilities

Portable CIP system for cleaning the tanks

Steam boiler for brewhouse heating

Water treatment for brew water

Oil free air compressor

Brewery lab instruments for beer quality test

To release a less than 200l of beer per day is unprofitable, so the minimum performance of our equipment is 200l.

If you have interest,please get in touch with me freely.