Description

| Medium size brewery plant 7bbl |

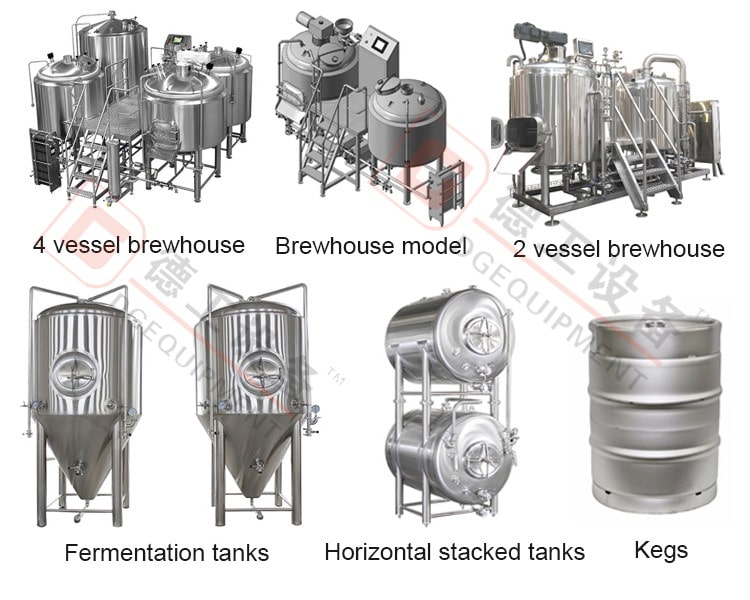

Turnkey Breweries (or“brewhouses”) are comprised of several key pieces of beer brewing equipment. The mash tun, lauter tun, brew kettle, and whirlpool, in the hands of a skilled brewmaster, convert grain that has been milled through a specialty grain mill, into a sweet liquid called “wort”. Wort is then fermented and finished in specialized beer tanks called fermenters, lagering tanks and brite tanks.

The brewhouse is both the heart and engine of the brewery where several critical processes in the creation of craft beer and kombucha are performed. Turnkey breweries, along with other key pieces of brewing equipment, vary in capacity, features, and complexity, but all brewhouses share the need to wet grain, separate the wort from the grain, and boil the wort with a heating source.

The three most common brewhouse heating sources are:

Steam: If it is choosen,a steam boiler will be equipped. three types:electric,gas and diesel boiler.The benifit of steam heating is heating quickly and even.

Indirect Fire: for example in Afirca,south America,these customers usually choose the type beacuse the electric cost is expensive for them.

Electric:For the small or medium size,electric heating is better choice.If you have a stric control using boiler in your country,the option is ok for commercial breweries.So that you can use any type.

Turnkey brewery brewhouse system 7bbl

Brewhouse tanks details:raker;sight galss;wort pump;spent grain hatch with chute

We offer three turnkey microbrewery plant models including the popular…

Mini brewery – 2BBL 3BBL capacity brewhouse (electric)

medium model brewery– 5 to 10 BBL capacity brewhouse (steam, indirect fire, & electric)

commercial brewery – 7 to 30 BBL capacity brewhouse (steam & indirect fire)

Our turnkey breweries will shorten your day while they save you money for years to come.

Our microbrewery plant provide brewers with several key advantages:

A worldwide reputation for industry-leading design, engineering and fabrication

Built with and tested by some of European’s leading craft brewers

Environmentally friendly and energy saving

Save Time and Labor

Ergonomics and Safety

Excellent fermentation tanks microbrewery plant

7 to 200 Barrel Fermenters Specifications:

All fermenters use dimple jacket technology and multiple zones to maximize glycol cooling performance, allowing the brewer to crash cool beers and maintain lagering temperatures. We manufacture fermenters in all the most popular sizes: 7, 10, 15, 20, 30, 60, 90, and 120 barrels, but can create any volume you wish, up to 200 barrels.

Horizontal lagering tanks are available as well. A controls package is available which includes a temperature controller that mounts directly to tank and a glycol solenoid valve. Unitank kit available which includes carbonation stone and port for function as a brite tank if necessary.

| Contact Alice today |

Talk to us about your requirements and we will design a system to work for you and your company. wlcome to consult brewery to get a perfect quotation.