Description

| Turnkey 800L brewery equipment for business |

From the initial designs to the final installation.

We build 50L to 200HL beer brewing system.The heating mode can be selected according to the requirements of customers, including direct fire heating, electric heating and steam heating (diesel,gas or electric) .

800l brewhouse breweries with 15bbl hot liquor tank

Skid mounted copper breweries made installation easy

Factory Craft Beer Brewery Equipment

We have a strict production system and a perfect after-sales system, for many beer lovers to achieve the dream of professional brewing beer, won the praise and recognition of customers.

304/316 food grade stainless steel

Argon arc welding, internal and external polishing, no welding dead angle

Pickling and passivation inside the tank

Complete cleaning system to avoid the production of bacteria

Beer Brewhouse Customized ( Two/three/four vessel ) brewhouse

Mash tank+Lauter tank+Kettle tank+Whirlpool tank

Upper glass visible manhole

CIP cleaning rotating washing spray ball

Sanding belt for welding protection of board surface

4*Stainless steel legs

Necessary pipe fittings valve fittings

We offers flexible Brewhouse designs to ensure that optimal efficiency is achieved while including all requirements that a customer may have (such as spacing, tank distribution, etc.) Producing a high quality beer requires consistent brews and although experience plays a crucial rolein the process, the limiting factor is the quality of the Brewhouse being used. Having a high quality Brewhouse will ensure that you have the necessary tools to keep the same flavor profile with every batch.

High qualitybreweries fermentation tanks are running

Conical breweries fermentation tank

Lower cone design: cone seal 60° angle (conducive to yeast discharge)

Cooling method: Miller version jacket, reasonably designed cooling area

Cleaning method: fixed all-round rotating cleaning ball,

Temperature measurement method: PT100 resistance

Control system: automatic temperature control

Manhole form: side manhole,

Auxiliary equipment: hop addition port, cleaning valve, sewage valve, sampling valve, mechanical pressure regulating valve, breathing valve, ice water solenoid valve, etc.

Kegs washer Auxiliary equipment

Breweries

| Microbreweries |

| Simple microbreweries with the infusion wort brew machine for beginners, home brewers and starting craft breweries. Production capacities from 50 liters to 10 hectoliters per each brew cycle. |

| Classic breweries |

| Interior breweries for restaurants with copper classic luxurious design to production beer from malt, hops, water and yeast. Production capacities from 300 liters to 10 hectoliters per each brew cycle. |

| Modular breweries |

| Modular breweries that consist of several compact modules, with easy and quick installation and start up . Production capacities from 3 up to 10 hectoliters per each brew cycle. |

| Industrial craft breweries |

| Industrial craft breweries equipped with ergonomic brew machine. Production capacities from 10 up to 100 hectoliters per day. |

| Contact Alice today |

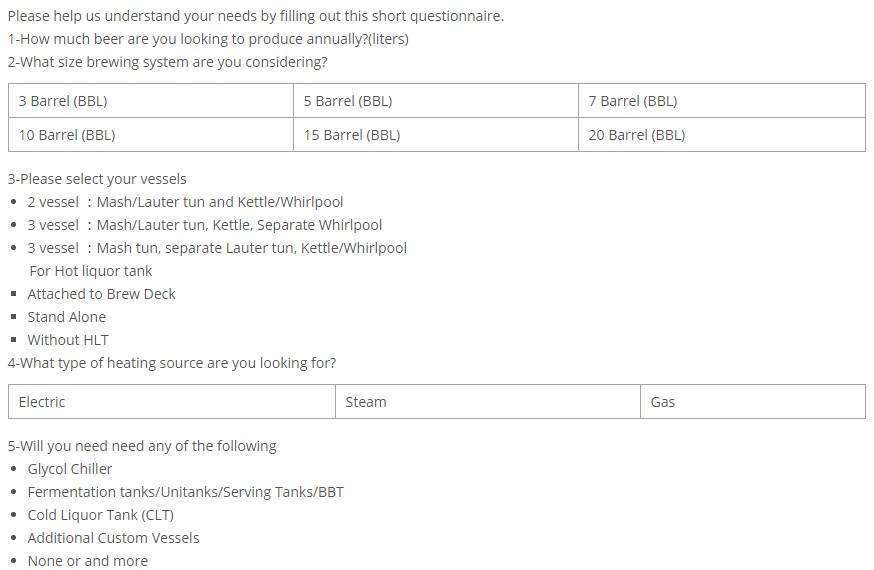

Talk to us about your requirements and we will design a brewing system to work for you and your company. wlcome to consult brewery to get a perfect quotation.