Description

| Decent Quality Beer Manufacturing Equipment |

35bbl brewing Vessel for brewing craft beer

Brew house system

A mash/ lauter tun (tank or vessel) is your primary piece.

In it you mash your malt and extract your sugar from the raw grain.It will also serve as your lauter (lauter is to wash).

After the mash, run a specified amount of water through the mash to bring the volume of the wort up to capacity.

There will be an electric stainless-steel pump for transfer. You will fire the kettle with gas or a steam boiler.

The kettle is a big tank for boiling. It will be direct fire with a gas burner or have steam jackets wrapping it. Steam is more efficient.

A hot-liquor tank is for bulk hot water heating. You can live without it but not recommended. Its primary role is to heat water for mashing.

Your brewhouse pump will transfer your raw wort through a heat exchanger. The heat exchanger is a tall block-shaped device made of layered plates. 200° wort goes in one side, 40° (or ambient) water goes in the other. This counterflow process cools your wort in 30-40 minutes. A cold liquor tank really comes in handy.

Fermenters brewing vessel in brewery building

Fermentation & maturation system

Fermenters are the vessels in which raw wort transforms into beer.

As seen in the photo, they are cylindroconical. They have a 60° cone that facilitates the drop out of solids once fermentation is complete: dead yeast, proteins, hops, and the healthy yeast too.

This is to effectively clarify the beer.This is one of the time-consuming aspects of brewing.

Fermentation will last 7-14 days for ales and 21-35 days for lagers.

You will need to have ample fermentation equipment set up and ready to store and monitor the progress of your beer.

Brite tanks are beer tanks used for storage, conditioning, carbonation, and packaging. Beer bright tank will have dish bottoms and sight glasses. They will also have ports for a carbonation stone and sample cocks for measuring CO2 volumes.

They are cheaper than fermenters as the dish bottoms are single-walled and easier to make than cones.

A cooling system

Glycol tanks have cooling jackets. They are double-walled stainless-steel, insulated and have large sections for the circulation of coolant- propylene glycol.

A glycol chiller has a large reservoir as well as a refrigeration compressor. It keeps the glycol at 28-30° F.

As you circulate this through the fermenter or Brite-Tank jackets, the beer is finished, aging, or being prepared for packaging.

Glycol chilling keeps the beer stable and inhibits bacteria growth and prepares the beer for sale.

Stainless steel brewing vessel bright beer tanks

Customer’s feedback

We chose DEGONG because they offered comprehensive support to our needs. Whether that was being very open and flexible with customization, working overtime for us to get out project completed on time, to helping us get the equipment into the building, and stood up.

—-John

Everyone claims to be custom manufacturers, but DEGONG truly does original designs and custom building of equipment. If you have an idea, they can help you design and build it.DEGONG team has helped us to continue to grow, increase our productivity and make better quality beer through better tank designs and stellar service.

—-Michael

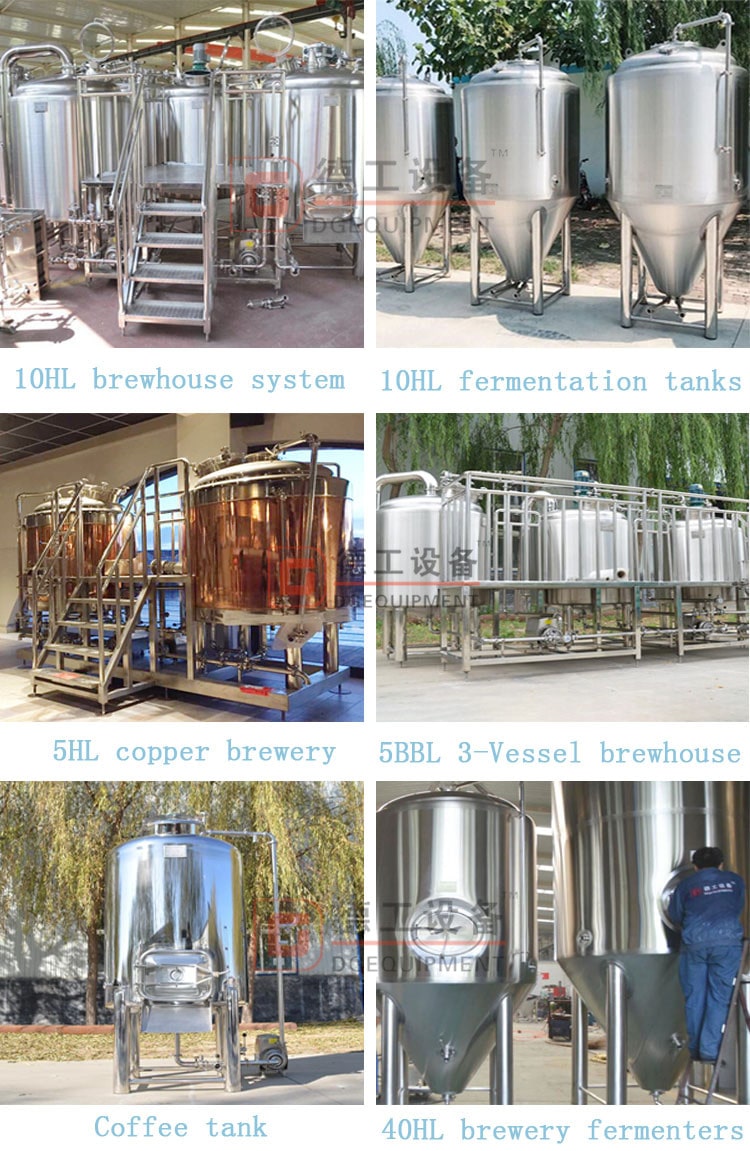

Breweries Project display

| Contact Alice today |

Talk to us about your requirements and we will design a system to work for you and your company. wlcome to consult brewery to get a perfect quotation.