Description

A complete brewing process requires many brewing parts. Milling, brewing, heat exhange, fermentation, maturation, filling, packaging, water treatment, filter and other auxiliary equipment.

Brewing is the production of beer by steeping a starch source (commonly cereal grains, the most popular of which is barley) in water and fermenting the resulting sweet liquid with yeast. … Most beer is fermented with a brewer’s yeast and flavoured with hops.

| Brewhouse system : |

Stainless steel brewery equipment with hot liquor tank

We outfit 2, 3, 4 vessel and combination “combi” systems. Tank design, platform design, automation features and process piping are a few of the multiple ways in which DGET designs for space,for budget and for expansion.

Work platform with staircase and guardrails. The central layout provides easy access to all workstations and connections, as well as great control and supervision over the entire work process. The anti-slip and washable surface provides a safe work environment and easy maintenance.

Material: Stainless steel 304

Detail drawing of brewing equipment:

Feeding and infiltration

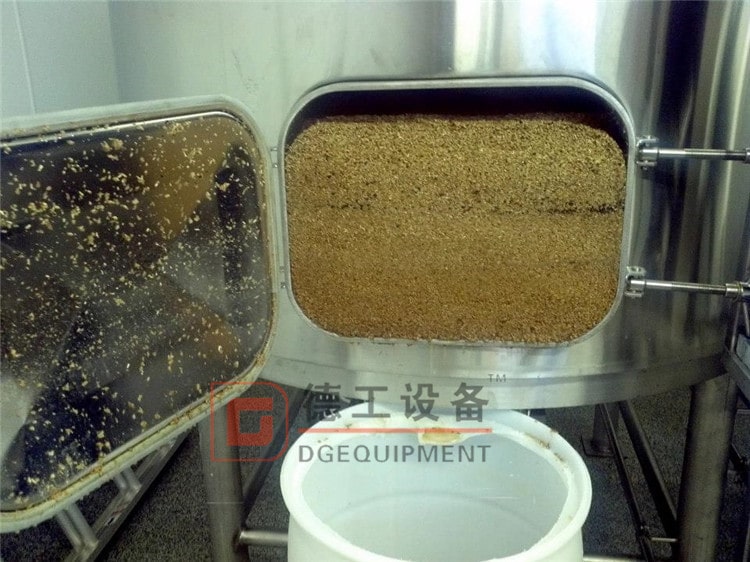

Spent grains port(Stainless steel brewery)

Raker;false bottom;wort pump;

working platform and sight light

Standard Brewhouse configuration:

1. Mash / Lauter Tun with side grain out access

2. Brew Kettle / Whirlpool Vessel with integrated steam jacket and temperature control

3. Semi-Automated Controls with PLC & Remote Access Support

4. 304 Stainless Steel Sanitary Pumps with VFD Controls

5. 304 Stainless Steel Plate Heat Exchanger with integrated temperature controls

6. Manual Sanitary Butterfly Valves

7. Ergonomic and efficient 304 stainless steel Brew Deck with easy access to all vessels and brewing functions

8. Semi-auto control cabinet

9. High accuracy temperature sensor, PT100

10. Heating: dimple steam jacket/ stainless steel electric heating elements

11. Usage:Pub/hotel/restaurant beer brewery equipment

Options:

· Full-Automation PLC Control System

· Hot Liquor Tank –Designed and Sized for Double Brew efficiency

· Cold Liquor Tank –Fully insulated and integrated

· Mash / Lauter Tun Rakers

· Air Actuated Automatic Butterfly Valves

. All brewhouse pipelines are used automatic argon protect welding.

Brewhouse Details:

. 2,3,4 and 5 vessels can be avaiable

. All the tanks materials are made by 304 Stainless steel

. 304 stainless steel operate platform and stairs

. Glass manways

. 100L-20000L volume system can be available

. Grain mill and screw conveyer (optional)

. Plate heat exchanger

. Stainless steel 304 pump with ABB or Siemens motors

. Automatic and Semi-automatic control for choice,PLC or mobile control can be available

| Fermentation tank features : |

The fermentation area consists of a specific (at the customer’s choice) number of CCT (cylindrical-conical tanks) of a corresponding capacity and a control panel containing the automation for maintaining the desired beer temperature inside each CCT.

CCT have a cooling jacket over the entire height of the cylindrical part. CCTs from 1000 liters also have a separate cone cooling jacket. Insulation is warmed by polyurethane foam 7-10 cm thick. The external covering of CCT is made of food mirror stainless steel.

stainless steel brewery In cellar

CCT equipped with:

top or side (at the choice of the client) the inspection sealed hatch;

a small hatch for a yeast (option for a side hatch);

fittings for connecting CIP-station and carbon dioxide baloon;

rotary washing head;

bottom valve for draining yeast sediment and washing liquid;

tap for supply wort and beer drain;

sampling valve;

beer temperature sensor;

The CCT is designed for internal pressure and can be used both for the primary fermentation and for the maturation (carbonization) of beer and the supply beer for filtering or bottling. The working pressure inside the CCT is up to 1.5 bar or up to 3 bar at request.

Washing of the CCT inside takes place in the automatic closed mode using a stationary or mobile CIP-station.

Fermentation tank components(stainless steel brewery)

| DGET |

Whether you are a start-up, a well-established craft brewery or a market leading brand – you can benefit from DGET in the brewery industry. Our catalog of high-quality equipment ranges from complete systems to process units to components.

Work shop

DGET’s certification

| Packaging & Delivery |

1. Main tanks, vessels and machines will be packaged with steel frames.

2. All items wrapped with soft package for protection.

3. Standard shipping containers will be used for general purpose.

4. All equipments will be loaded into containers according to exact container layout drawings.

5. After loaded into containers, all equipments will be well fixed to the containers.

Ready to ship

| Contact me |

If you are interested in our craft beer equipment, need a quotation or you simply want to discuss your project with us, get in touch and we will be happy to assist you.