Description

| 1000l craft beer equipment for businesses |

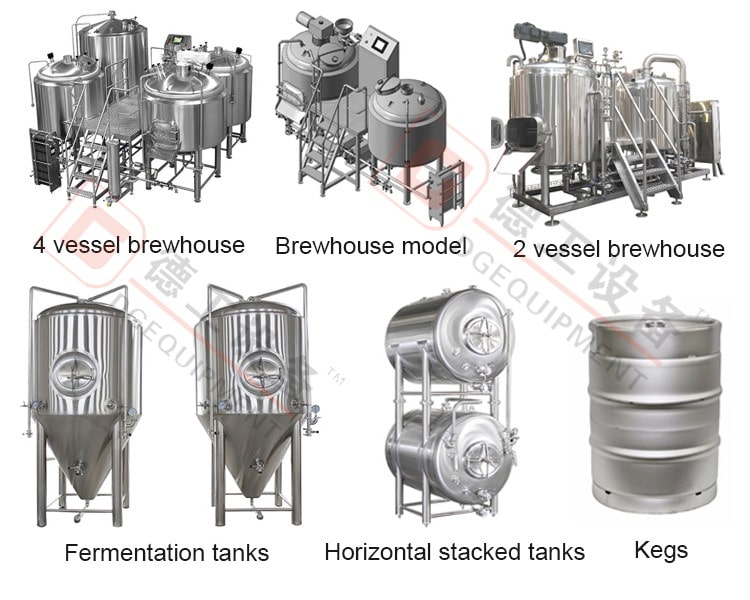

Degong beer equipment mainly includes seven systems: milling system, mashing system, fermentation system, cooling system, cleaning system, control system, beer selling system. The equipment is advanced in designing and manufacture and all process can realize semi-automatic.

01. Milling system: mill machine, malt lifting

02. Mashing system: lauter tank, mash boiling, whirlpool tank, hot water tank, wort pump, plate heat exchanger, saccharification combination pipeline, pipeline & valve, wort measuring meter, venturi tubes, operation platform

03. Fermentation system: fermentation tank, bright beer tank, yeast adding tank, food tube, refrigerant pipelines(keep warm tube), electronic gauges, valve pipe fittings, electromagnetic put air out

04. Cooling system: ice water tank, refrigerating unit, circulate pump, pipelines & valves

05. Cleaning system: washing pump(removable), alkali tank, sterilization tank

06. Control system: mashing control, fermenting control, cooling control, cleaning control

07. CIP system: includes the alkali tank, sanitary tank and washing pump, all is on a wheeled chart

2 vessel brewhouse system beer equipment

Key Specifications/Special Features:

1000L beer brewery equipment micro brewery equipment

Main tank: mash/lauter tank, kettle/whirlpool tank, hot water tank, fermentation tank, bright beer tank

Capacity: 1, 2, 3, 5, 8, 10, 15, 20HL or customized

Service: main machine guarantee for 18 months

Accessories and electronic components will have one year free warranty

Supplying lifetime maintenance and technical service

Details of equipment:

| Mash/lauter tank |

Effective volume: 1000L Total volume: 1300L |

Inner-shell: (SUS304) TH=:3.0mm External-shell (SUS304), TH=2.0mm Insulation layer: PU-thickness 100mm |

| Kettle/whirlpool tank |

Effective volume: 1000L Total volume: 1300L |

Inner-shell (SUS304), TH=3.0mm External-shell (SUS304), TH=2.0mm Insulation layer: PU-thickness: 100mm Top manhole: round glass manhole 360° coverage CIP spraying ball Temperature measurement way: PT100 Heating way: steam heating/electric heating/direct fired heating optional Sanitary leveling sight glass at the back of kettle, tangential whirlpool inlet |

| Hot water tank |

Effective volume: 1000L Total volume: 1300L |

Inner-shell: (SUS304) TH=:3.0mm External-shell (SUS304), TH=2.0mm Insulation layer: PU-thickness: 100mm Top manhole: round glass manhole Temperature measurement way: PT100 Heating way: steam heating/electric heating/direct fired heating optional |

| Fermentation tank |

Effective volume: 1000L Total volume: 1300L |

Material Inner (SUS304) Thickness: 3.0mm Outer (SUS304) Thickness: 2.0mm External-jacket (SUS304) Thickness: 1.5mm Surface: finish 2B/cold-rolled, annealed Inner surface treatment: welds grinded to Ra 0.6μm (attached 360 degree Omni cleaning ball) Mirror surface finish inside Insulation: polyurethane-thickness:100 mm Equipment with cone 60 Heat exchange area: 2.87m2 |

| Brite tank |

Effective volume: 1000L Total volume: 1200L |

Material inner (SUS304) Thickness: 3.0mm Outer (SUS304) Thickness: 2.0mm External-jacket (SUS304) Thickness: 1.5mm Surface: finish 2B/cold-rolled, annealed Inner surface treatment: welds grinded to Ra 0.6μm (attached 360 degree Omni cleaning ball) Insulation: polyurethane-100mm |

Fermentation tanks in brewing factory

Unload beer equipment fermenters

Beer Equipment needed for the brewing process

Our chillers can be found in hundreds of breweries around world. The criticality of the cooling system in a brewery must be carefully considered.

Industrial beer brewery equipment usually for the brewery factory.The capacity can be from 1000L to 100HL.The industrial brewery factory we have done is the 10HL.

Before your inquiry,pls confirm these information firstly:

1.The mash system capacity you want?

2.The mash system combination type you want?2vessels,3vessels or 4vessels?

3.The heating method you want?

4.Do you need the hot liquid tank?

5.The fermentation tank capacity and quantity you want?

6.Do you also need the brite tank?If need,the brite tank capacity and quantity you want?

Pls confirm these questions,then we will quote you as soon as possible according to your requirements.

| Contact Alice today |

Talk to us about your requirements and we will design a system to work for you and your company. wlcome to consult brewery to get a perfect quotation.