Description

| Craft brewing tank equipment for business |

“brewing” is the practice of regulating the interactions between water, starch, yeast, and hops so that the end result is what is called beer.

Of course, the actual process of brewing is a lot more complicated (full of terrifying terms like lautering, wort, and other). It’s the job of the brewer to have as much control over as many elements as possible so that the end result is close to what he or she had in mind.

2-vessel craft brewing systems for mashing

When we brew a beer, we are preparing a certain amount and variety of grain to produce those sugars, and then adding yeast so they can feast and create alcohol. If you can wrap your head around that, you can grasp the concept of brewing.

large craft brewing systems fermenters

To get a little deeper into brewing, here is a breakdown of the basic steps, with a few key terms:

- A starch source, typically a grain (and typically barley) is malted, or allowed to partially germinate and then dried. This partial germination makes for easier conversion of the grain’s starches into sugars.

- In the mash stage, the malted grains are introduced to water and a certain amount of heat to enable the natural enzymes in the grain to convert its starches into fermentable sugars.

- The mash is then lautered, basically filtered to remove the solids.

- The remaining liquid is then boiled. Hops may be added both at the beginning of the boil and, depending on the kind of beer being made, toward the end. The result of the boil is called the wort.

- The filtered wort is cooled to a specific temperature, at which point yeast is added so that the process of fermentation can begin.

- Fermentation may be done in a variety of vessels, and may be followed by a period of conditioning (further aging away from dead yeast cells) or secondary fermentation.

- However you store it, when you pour it, the result will be beer.

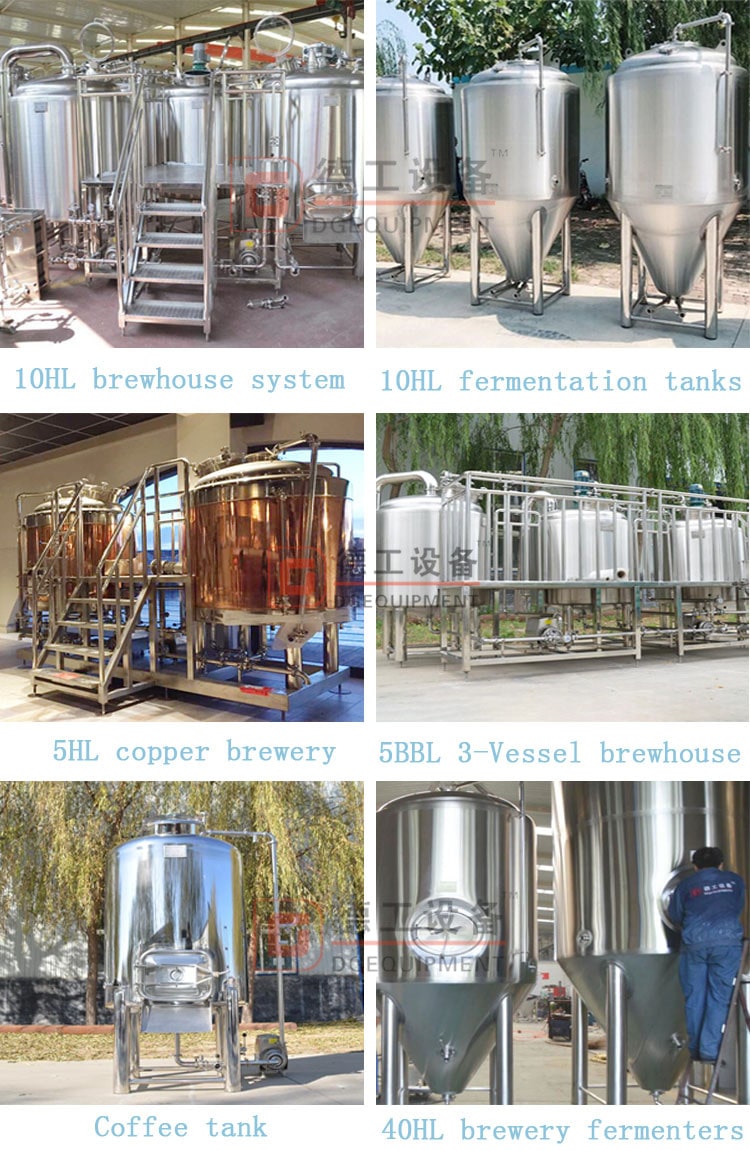

Brewing tanks display of DEGONG Supplier

Craft Brewing Systems Project display

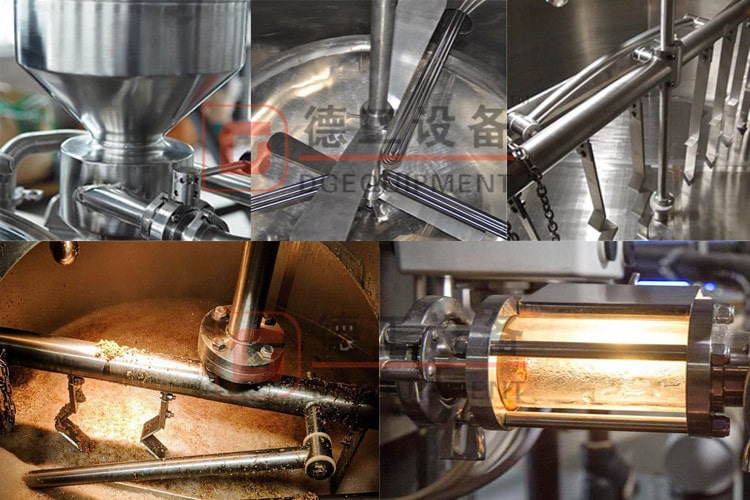

Side door with chute

craft brewing systems details:Grist hydrator;agitator;raker;sight glass

Install fermentation tanks craft brewing systems

Beer brew equipment is typically smaller than independent micro brewery equipment. We offer medium beer brew equipment with the productivity of 500L (5 hl) to 5000L (50hl) per brew. The red copper brewhouse is also the preferred choice for most brew pub. The fermentation tanks for brew pub is usually not large but with more numbers for serving more beer flavors on taps. Sometimes the serving tanks or kegs installed in walk-in cold room are also required behind the tap counter. We supply the beer making machine for a basic process to make beer from malt. A typical brewing process for brew includes milling, mashing, fermentation, maturing, cooling, controlling, cleaning, filling and beer serving.

| Contact Alice today |

Talk to us about your requirements and we will design a system to work for you and your company. wlcome to consult brewery to get a perfect quotation.