Description

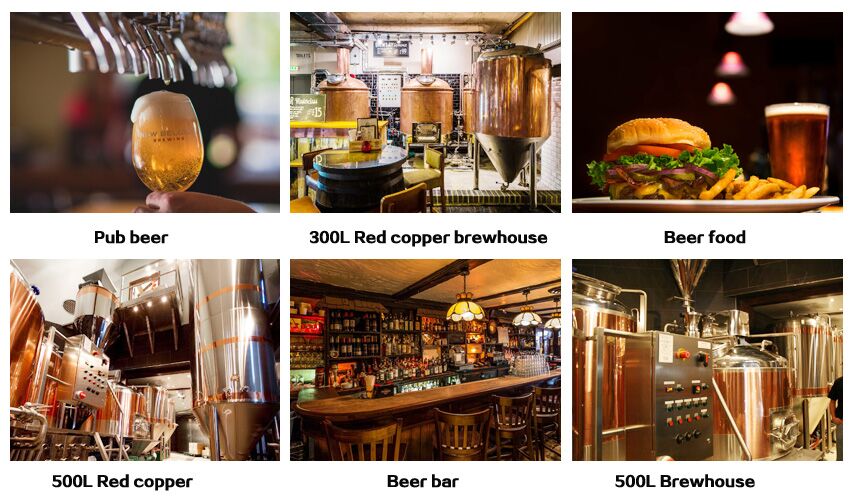

Insulated beer fermentation tank/ CCT is the most used and most important part of a whole set of brewery equipment. CCT is the tank in which yeast can reproduce themselves at the first stage and release Co2 by anaerobic respiration at the second stage. Due to the foam formed by fermentation, so generally 25% head space should be reserved when designing tanks. 60 degree cone angle is designed for helping the suspending yeast slipping down to the bottom. CCT is sometimes used as beer maturation tank by adding a carbonation stone. The design of temperature control makes the fermenter more easy to operate.

Insulated conical beer fermentation tank

- Made of food grade stainless steel 304(AISI304)

- 4 stainless steel legs with leveling footpads

- Design pressure: 3.0 bar Working pressure: 1.5-2 bar

- Mirror polishing inside, surface is grinded to Ra0.6μm. Polished all internal surfaces, polished welds. External steel jacket with all welded connections and grinded surface

- Thickness of inner shell: 3.0mm outer shell: 2.0mm dimple jacket: 1.5mm

- With insulation(polyurethane).

- Shadowless side manhole and rotating raking arm

- With dry hopping port at the top

- CIP pipes is alongside the vessel which can clean the tank thoroughly through sanitary spraying ball

- Dual cooling zone at the side and conical bottom

- Carbonation stone is an optional component for the fermentation tank. If you want to mature beer in the fermentation, then you need to add it.

- Pipes supporter are included

- All necessary accessories are included such as release valve, pressure gauge, sample valve, temperature probe, valves, solenoid valves, connecting pipes, etc…

- Certificated sanitary food grade SS304

- High quality valves & components

- Dual cooling areas which is easy to operate and good for saving energy

- At least 25 years using life

- Easy to maintain, operate. Saving time and labor

- All fermentation tanks should pass the tank leakage test before leaving our factory

- Carbonation stone port for special use

- Fine welding seams treatment

- More economical and competitive

- Completely customizable as requested

- CE, ISO, TUV approval

- With tubular level meter for special use

- Novel structure and attractive appearance

- More humanized design

- Warranty period:2 years

Contact me at:

Email: [email protected]

WhatsApp/Tel: +86 15863177821

Skype: swift05

Hope to hear from your soon! 🙂