Description

Specification for 7bbl 2 vessel brewing brewhouse

Mash/Lauter tun:7BBL

Grist hydrator on top

Agitator with VFD

Side mounted grain outdoor with grain chute

Laser cutting V-wire False Bottom

Manual lifted scraper

Kettle/Whirlpool Tun:7BBL

Tangential whirlpool inlet

Sanitary leveling sight glass

Hot water tank 1000L

Sanitary leveling sight glass

Yeast feeder:30L

Tri clamp aeration port with ball valve

Heat exchanger:8M2

Completely 304 SS Corrugated plates

Pump:ABB, Sanitary SUS304, VFD control

Pipe and fittings:As design

Completely SS304, Work Platform is included

2 vessel brewhouse system lauter tank with chute for moving spent grains

2 vessel brewhouse system lauter tank with chute for moving spent grains

Option:Customized

Grain Case

Grist Hydrator

Piping flow panel for Brewhouse

Brewhouse Separate PLC Controller

Brewing Brewhouse system 7BBL

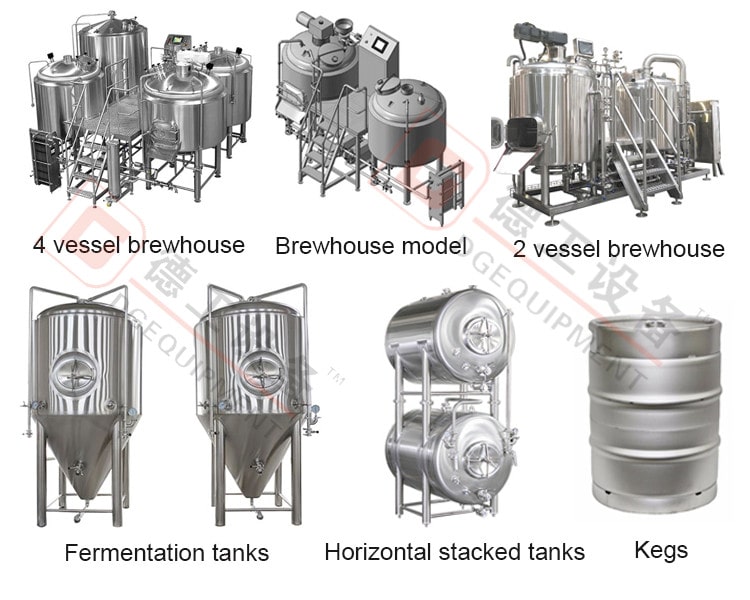

7bbl 2 Vessel Steam Craft Beer Brewing Brewhouse is widely in nano brewery, beer brewpubs and micro brewery system.

The basic construction is Mash/Lauter tank and Kettle/Whirlpool tank.

Single batch or double batches hot water tank depends on the scale of brewpub.

There are copper, stainless steel and copper appearance for optional.

Brewers make their beer attractive to consumers by unique brewing process and distinctive beer taste.

Some brewpub place beer pub equipment behind a glass partition that allows visitors to observe the process of making beer.

This is an excellent design solution from A to Z, includes grain miller, brewhouse, brewing tank heating machine,

Heat exchanger, fermentation tank, serving tank, cooling chiller, controller and CIP cleaning.

Delivery Term:

The manufacturing time is 30 – 50 working days, and will be commenced as soon the initial 40% deposit is received in DEGONG account and technical drawings are signed & confirmed by the client

Production will not start until all drawings, technical files or layouts are confirmed & signed by appropriate party. This can lead to delays in production and / or delivery time if not completed.