Description

Food water chiller low temperature glycol chiller for food

Model :DGET-20CL

No.:12

The use of air-cooled chillers and water-cooled chillers (or fluid process chiller systems) for dairy and food processing operations is a

critical part of producing safe and high quality consumer products. Specific to the dairy industry, according to the 97% of the milk

producing farms and food factory owned.

At DeGong Chiller Systems, we understand that many of our customers running factory owned dairy and food processing operations do

not have time, or no experience, to design fluid cooling systems for their operations. To meet this need, DeGong Chillers has engineers

available to assist our clients to make the correct equipment selections. In addition, DeGong offers both standard, pre-designed chiller

systems for specific food processing applications as well as custom design capability for customers who like to think out of the box.

1. Adopt well-known brand compressors, such as Copeland, Panasonic, Danfoss, etc.

2. Three types of evaporator for choice: stainless steel plate heat exchanger, stainless steel water tank with coils, shell and tube exchanger.

3. Equipped with sophisticated digital temperature controller can accurately control the temperature.

4. Cooling air discharges heat from top of chillers. No need of cooling tower, saving water and space.

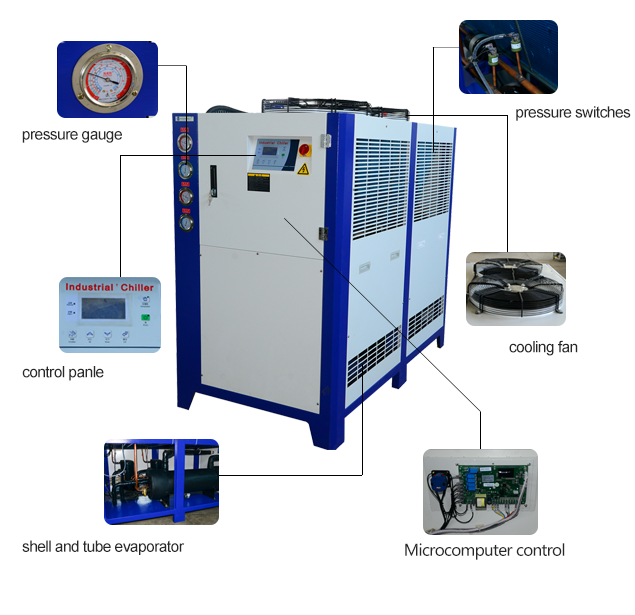

Product Perspective

Product details

| Scroll Type Food water chiller low temperature glycol chiller for food | ||||||||

| Model | DGET-10CL | DGET-12CL | DGET-15CL | DGET-20CL | DGET-25CL | DGET-30CL | ||

| Cooling capacity | 0℃ | kw | 22.8 | 24.8 | 33.4 | 44.2 | 50.5 | 66.9 |

| -5℃ | kw | 19.3 | 21 | 28.4 | 37.6 | 43 | 56.8 | |

| Input power | kw | 10.54 | 12.33 | 15.84 | 20.51 | 23.52 | 31.81 | |

| Power supply | 220V/380V/415V/460V, 50HZ/60HZ; 3PHASE | |||||||

| Refrigerant | Type | R22/R407C/R410a/R134a | ||||||

| Control type | Thermostatic expansion valve | |||||||

| Compressor | Type | Hermetic scroll type | ||||||

| Power | kw | 4.4*2 | 5.2*2 | 4.4*3 | 8.7*2 | 10.2*2 | 8.7*3 | |

| Evaporator | Type | SS Tank with coil or Shell and tube | ||||||

| Flow rate | m³/h | 4.32 | 4.70 | 6.33 | 8.37 | 9.57 | 12.68 | |

| m³/h | 3.97 | 4.32 | 5.84 | 7.73 | 8.85 | 11.68 | ||

| Tank volume | L | 200 | 200 | 270 | 350 | 350 | 450 | |

| Dia. Of inlet/outlet | mm | DN32 | DN32 | DN40 | DN40 | DN40 | DN65 | |

| Condenser | Type | High efficiency hydrophilic aluminum foll finned type | ||||||

| Fan power | kw | 0.46*2 | 0.46*2 | 0.55*2 | 0.78*2 | 0.78*2 | 1.32*2 | |

| Water pump | Type | Centrigual water pump | ||||||

| Power | kw | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 2.2 | |

| Head | m | 20 | 20 | 20 | 20 | 20 | 20 | |

| Protection system | Compressor overheat protection, high/low pressure protection,phase missing/sequence protection, flow rate protection, anti-frozen protection. | |||||||

| Machine Size | L | mm | 1560 | 1560 | 1800 | 2100 | 2100 | 2200 |

| W | mm | 850 | 850 | 1000 | 1000 | 1000 | 1160 | |

| H | mm | 1500 | 1500 | 1600 | 1700 | 1700 | 1900 | |

| N.G | kg | 450 | 500 | 750 | 850 | 900 | 1150 | |

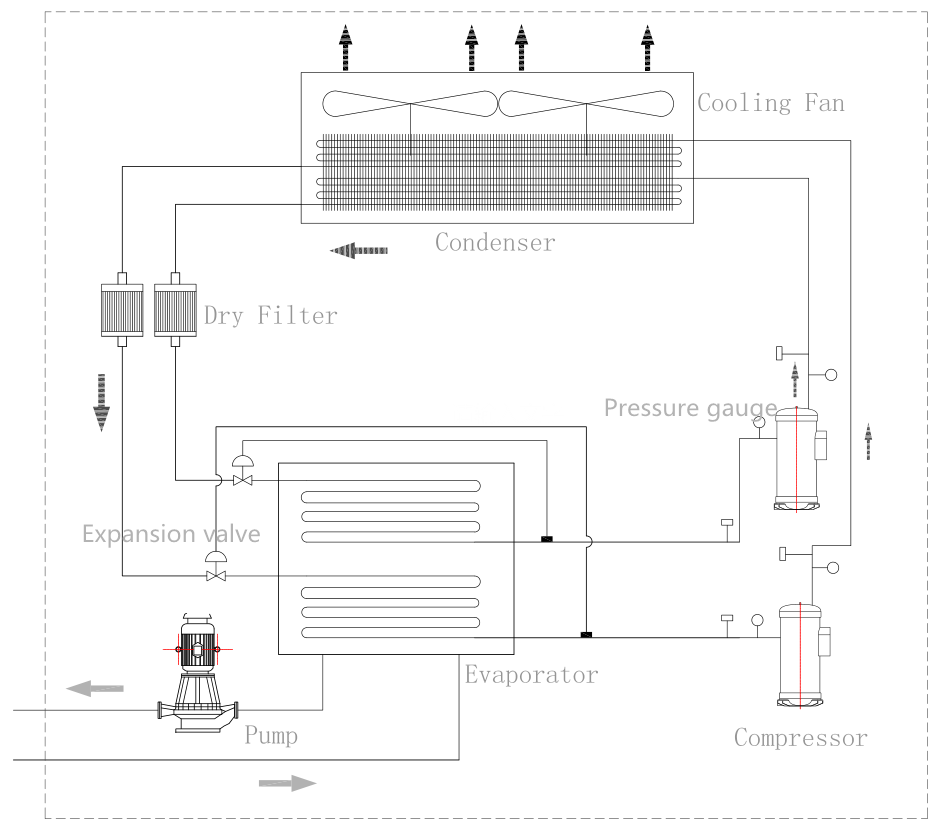

Working principle

Certification