Description

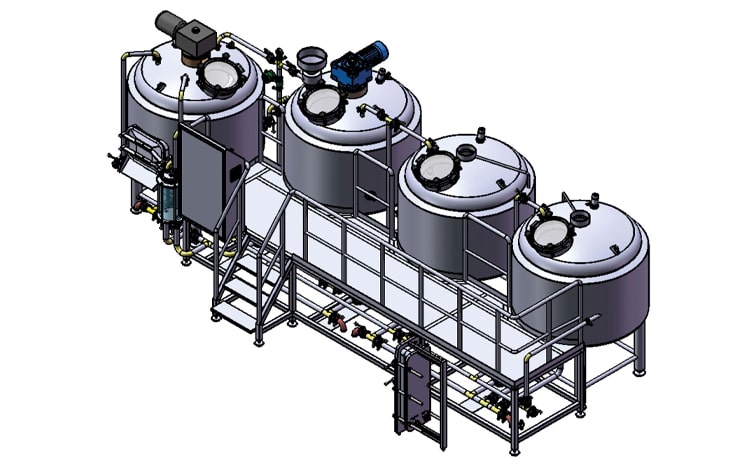

3000L industrial beer equipment overview

Malt milling machine

- Particle adjustable rolling crusher

- Flexible or steel auger to directly lift the milled grain to mash tun

3000L industrial beer equipment brewhouse mian feature

Heating method: steam heating

Hot &cold water recycle for saving energy

Automatic lifting agitator and raker system

Automatic agitator and raker system for maxing and spent grain .

Famous brand for pump and steam boiler.

Mash pipe has no dead corner for easy cleaning and brewing.

Continue production, 3-4batches per times.

Semi-Automatic or full automatic control system for optional.

3000L industrial beer equipment brewhouse advantage

Good abrasion resistance material

- Inner-Jacket(SUS304)thickness: 3.0mm

- External-Jacket thickness: 2.0mm

- Seal head thickness: 3.0mm

High quality insulation effect

Polyurethane thickness: 80mm

Beautiful weld and polish technology

All argon gas protection welding. Polishing precision up to Ra0.6µm.

Powerful technology supporting

Providing drawing of every tank and drawing the layout of the whole project according with customer’s workshop

World’s top brands’ electronic components

For example, we use Siemens PLC and touch screen, Schneider button of circuit breaker

Internal heating system to increase boiling intensity

ring&spary cleaning ball&spent grains hatch&raker&sight glass

ring&spary cleaning ball&spent grains hatch&raker&sight glass

3000L industrial beer equipment beer fermenter technical characteristics:

- All 304 Stainless Steel Construction

- Jacketed & Insulated

- Dual Zone Dimple Cooling Jacket

- Dish Top & 60° Conical Bottom

- 4 Stainless Steel Legs with Leveling Ports

3000L industrial beer equipment beer fermenter specifications:

- Working Capacity: 300L, 6000L, 9000L

- Inner Diameter: Customized

- PU Insulation: 60-100mm

- Outside Diameter: Customized

- Thickness: Inner Shell: 3 mm, Dimple Jacket: 1.5 mm, Cladding: 2 mm

3000L industrial beer equipment fermenter Includes:

- Top Manway or Side Shadow less Manway

- Racking Port with Tri-clamp Butterfly Valve

- Discharge Port with Tri-clamp Butterfly Valve

- 2 Tri-clamp Outlets with Butterfly Valves

- CIP Arm and Spray Ball

- Sample Valve

- Pressure Gauge

- Safety Valve

- Thermowell

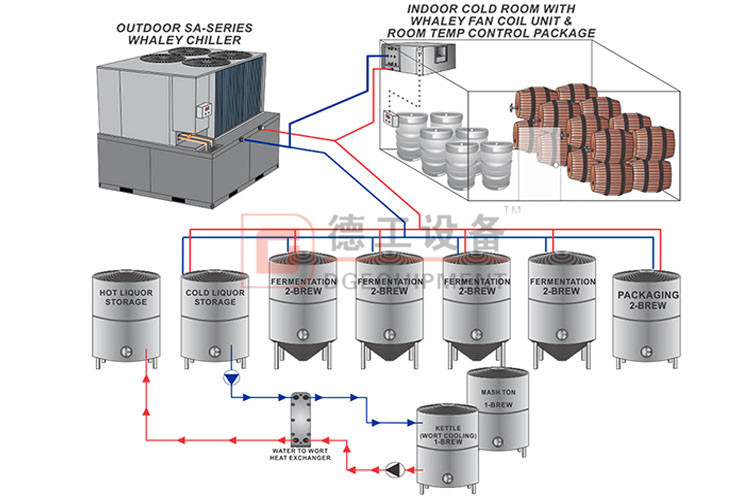

3000L industrial beer equipment cooling system

Insulated glycol water tank and cold water tank

Efficiency chillers or refrigerators with fryon to supply cooling energy

Sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger

3000L industrial beer equipment CIP system

Material SS304, Thickness for tank 2mm

Tank amount: Sterilization tank, Acid tank, Alkali liquor tank

Separate control for CIP unit.

3000L industrial beer equipment control system

PLC with touch screen panel and Industrial computer control system

Electrical controlling cabinet with temperature, on-off controlling for brewhouse

Electrical controlling cabinet with temperature, on-off controlling for fermenter automatic.

Temperature controller, thermocouple, solenoid valves etc.