Description

| 10bbl craft beer equipment for businesses |

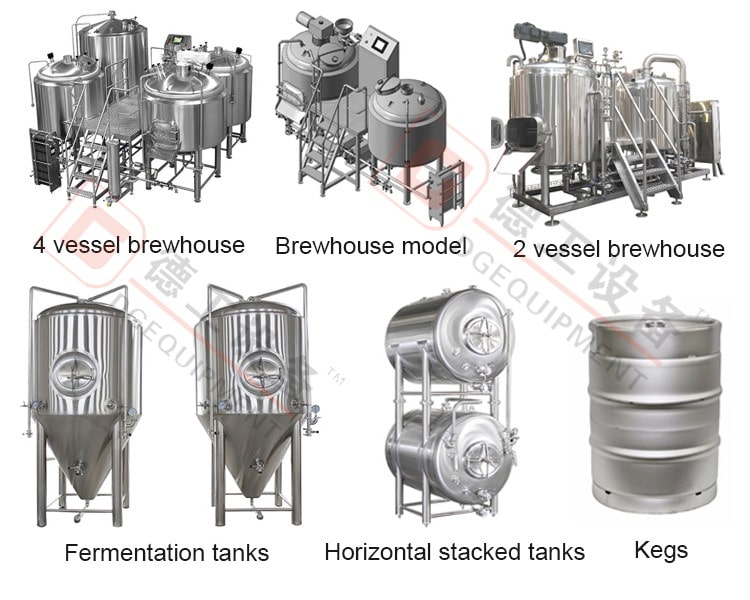

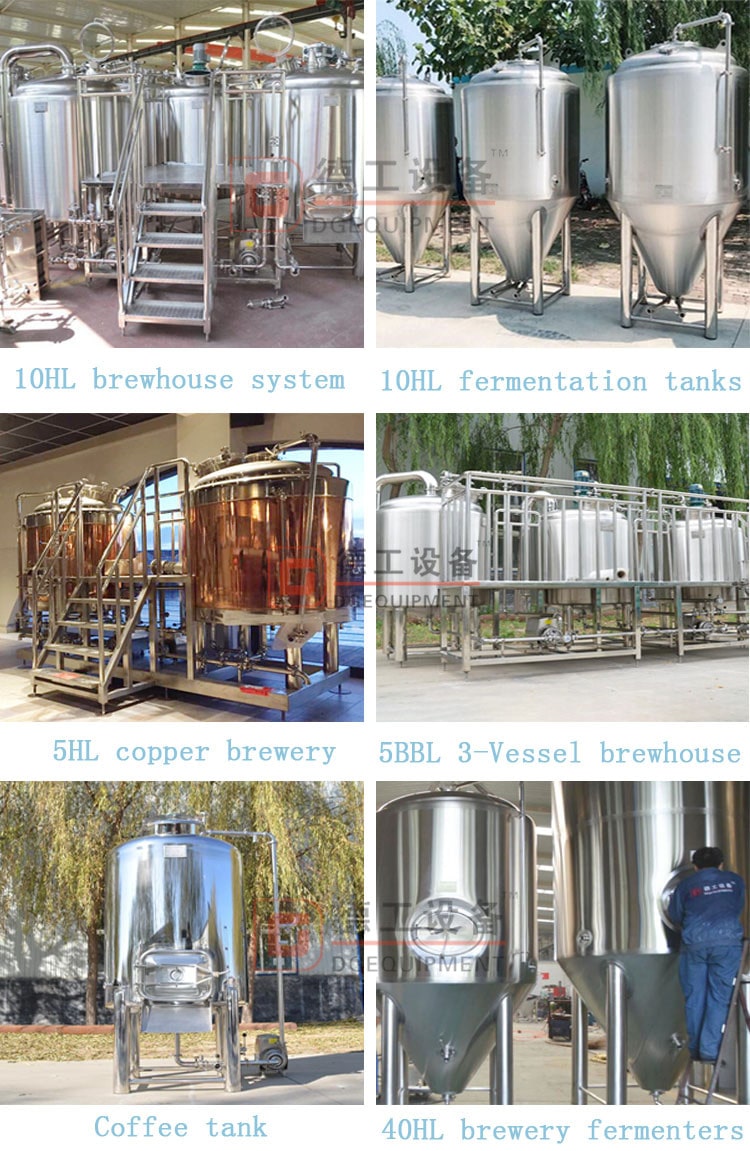

We are proud to offer brew houses, tanks and small parts to brewers across the country. Brew houses and fermenters from 3 BBL, ancillary components including steam boilers and chillers, stainless Tri-Clamp parts, yeast brinks and keg washers. We have some of the quickest lead times in the industry along with a huge inventory of tanks between 3-90 BBL in stock.

Our Brewhouses allow you to choose from various heating options (electric, steam, and direct fired), and select controls consistent with your style of brewing (including basic or advanced touch-screen panels), variable-speed pumps, Reduction Gear, platform and many more option available!

The brewhouses come in multi-vessel configurations brew kettle, hot liquor tank and mash/lauter tun included. We offer larger free standing 2 bbl to 30 bbl brewhouses.

Turnkey beer equipment breweries and neccessary tanks

Configuration

Grain miller for beer equipment equipped

2. Brewhouse Unit

Mash tun, Lauter tun, BrewKettle, Whirlpool tun in various combination

Hot water tank and cold water tank for optional in special

Infusion or decoction brewing methods are designed exactly

Stainless steel or copper cladding are popular

Two stages heat exchanger for wort cooling

Completely stainless steel integrated work platform

Sanitary and efficiency wort pump

All pipings and fittings

10bbl two vessel beer equipment brewhouse system

3. Cellar tanks

Fermentation tank

Standard stainless steel conical cylindrical fermentation tanks

size as brewhouse in restaurant

We can exactly calculate tanks quantity by fermentation cycle for various beers

Including all manhole, valves, pressure gauges, fittings etc

Bright tank

Standard stainless steel bright tanks for beer maturation, conditioning, service, carbonation

The same size or double as fermenter in restaurant or bar

Including all manhole, valves, stone, gauges, fittings etc

Strong fermentation tanks beer equipment

Technical Notes:

1.All Construction is from SUS 304 food grade stainless steel, all pipes are SUS304

2.All signs & wording in English

3.All tanks with Manufacturing Plates

4.All tanks will be tested and inspected in the NDT room after construction & Quality Control Checks

5.All jackets will be tested using water pressure testing, testing pressure: 0.3Mpa (3 Bar) & working pressure:0.2Mpa (2Bar)

6.All tanks to test for 48hours before leaving the factory;

7.All the welds are full TIG welded by water spray method to ensure uniform weld pattern with full pickling & passivation

8.All tanks are mirror polishing inside, to be Ra 0.4um.

DEGONG provided warranty

We provide 3 years warranty on tanks sold without manufacturing defects from the factory. but we does not cover damage to tanks from unloading of tanks at customer site, damage resulting from improper use of tanks for products other than beer or appropriate beverage, damage from exceeding designed tanks pressure.

| Contact Alice today |

Talk to us about your requirements and we will design a system to work for you and your company. wlcome to consult brewery to get a perfect quotation.