Description

Microbrewery setup 500L

- Malt mill – grinder

A mill for malt – with production capacity from 150 to 200 kg per hour, for preparation of malt grist.

A powerful electrical mill for preparation of malt grist from malted grains. Extremely wide cylinders ensure the required access to endosperm without any damage of external parts of grains, that are important for later easy filtration of wort through a grains layer during a wort processing. We recommend model of mill for the medium microbreweries (with a volume of the brewhouse up to 600 liters.)

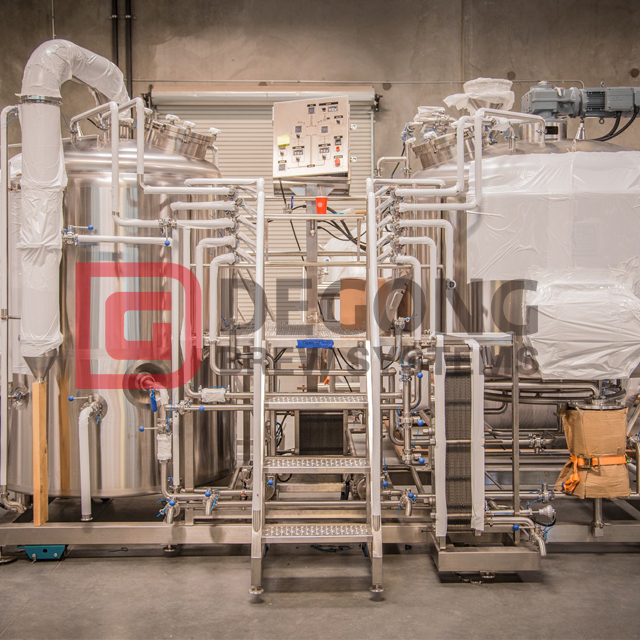

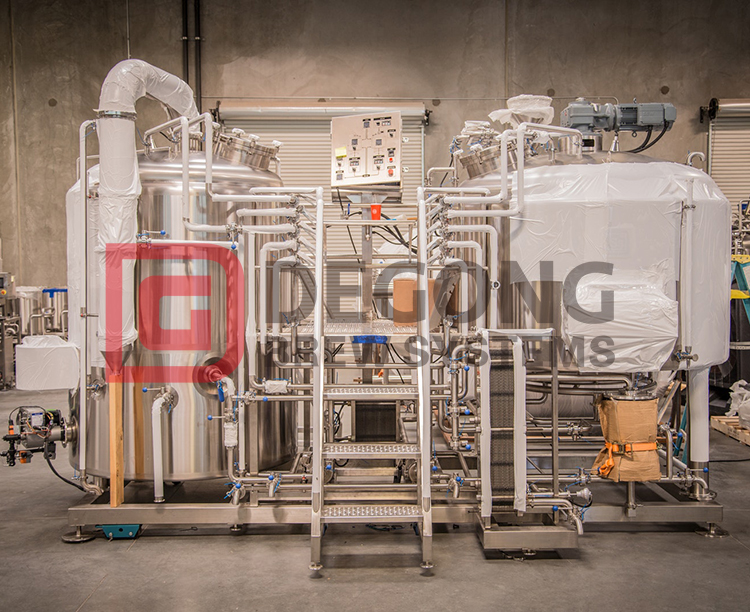

- Compact brewing module

Brew machine for the production of hopped wort. The most important technical step in the beer production process is the brewing of the wort. Milled malt or malt extract is mixed with water an then is boiled with the hops to produce the final product – wort. This module includes the main machine in the brewery. The equipment includes the wort boil tank with the steam heating system, filtration tank for separation of solid parts from wort, whirlpool tank to separation of hops from wort, all necessary pumps, pipes, control system, service platform, laboratory washbasin for chilling of wort samples, electric cabinet with central computer, main frame with adjustable feet.

Compact brewing module 500L Microbrewery

Compact brewing module 500L Microbrewery

2vessel brew tank

A typical two-vessel Combination Mash Lauter Tuns are the first combination vessel in these brewhouses line ups. Next inline is the combination of the Kettle and Whirlpool tanks.

3vessel brew tank

A three-vessel brewhouse is hybrid system that incorporates at least one combination vessel and two dedicated process vessels.

4-Vessel brew tank

A typical four-vessel brewhouse will include a Mash tun, Lauter Tun, Kettle and Whirlpool. Each of these tanks is dedicated to performing a single process, and is designed differently than similar vessel used for performing multiple processes.

Microbrewery brew machine wort making tank

Classic 500/600 Wort brew machine – the brewhouse

Classic 500/600 is a compact wort machine which includes all necessary equipment to produce 590-708 liters of wort (needed for production approximately 500-600 liters of beer) in one brew batch from malt (or malt extract or wort concentrate), hops and water. The wort brew machine is the main part of the Classic 500/600 modular breweries.

The wort is an intermediate product in the beer production process. The next phase of the production cycle is fermentation and maturation of wort.

We delivery the Classic 500/600 wort brew machine fully assembled on the basic stainless steel frame with all fittings needed to connection with other parts of the brewery using special hoses. Therefore there is not needed to install the brew machine by our technical specialists on the place. The installation is provided by customer – this way we save his costs.

Build yourself your own microbrewery from prefabricated modules within a few hours in a normal restaurant kitchen. The unique and inexpensive solution allows the gradual expansion of the brewery without a large investment, without designing, assembly team and special workers.

Microbrewery fermenters

Production capacity – daily :

500 liters of beer wort per day→one batch within 12 hours→source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

1000 liters of beer wort per day→two batches within 24 hours, source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

1500 liters of beer wort per day→three batches within 24 hours