Description

Here you will find a range of brewery fermenters with work capacities ranging from 100 to 10,000 barrels. We can also customize any fermenter to the size and specifications required by your brewery. A copper cladding can also be provided instead of a stainless steel cladding. Please call us at +86 18363007358 for a custom quote.

The 7bbl equipment is equipped with a hot and cold water tank, including a filter tank, a smashing bucket and a whirlpool, and it also uses an automatic waste detachable system.7 Barrel Brewhouse: Superior Small Batch Brewing

- 3-vessels:1000l lauter tank,1000l mash/kettle tank,1000l whirlpool tun(with 2000l hot liquid tank and 2000l cold water tank)

- steam heating method

- Inner thickness:3.0mm,outer thickness:2.0mm,jacket thickness:1.5mm

- insulation:polyurethane,thickness:100mm

- Useful capacity:1400L,total capacity:1000L

- Heavy duty false botton with pillar support system

- Fully insulated vessel

- SS CIP High-flow rotary spray ball with 360 degree of coverage

- Interior light

- Sparge ring assembly

- Top mahway(tempered glass)

- Side manway for spent grain out

- Gap of the sieve is 0.7mm

- automatic spent grain removable system

The whole system contains

Mill system:

- mill machine mill the malt to meet the standard that broken but not crushing.

- use the malt liftingmachine to transfer it to mash tanks.

Mashing system:

- mashing is a process of leaching wort.Maintain a certain time at a certain temperature to reach biggest activity of different enzymes,and improve the malt’s utilization rate as soon as possible.

Fermentation system:

- the fermentation process is converting the wort to alcohol.It is very important to control the fermentation temperature.Because it could be produce many by-product that influence beer’s flavour.

Cooling system:

- The one function of cooling system is to cool fermentation tank and maintain a certain temperature degree.The other function is to provide ice water for plate heat exchanger

Control system:

- The control system control the whole process of beer brewing,and it is semi-auto control system.

Cleaning system:

- The cleaning system contains alkali tank,sterilization tank and cleaning pump.Cleaning process contains advanced cleaning mash and after brewing cleaning.The after cleaning

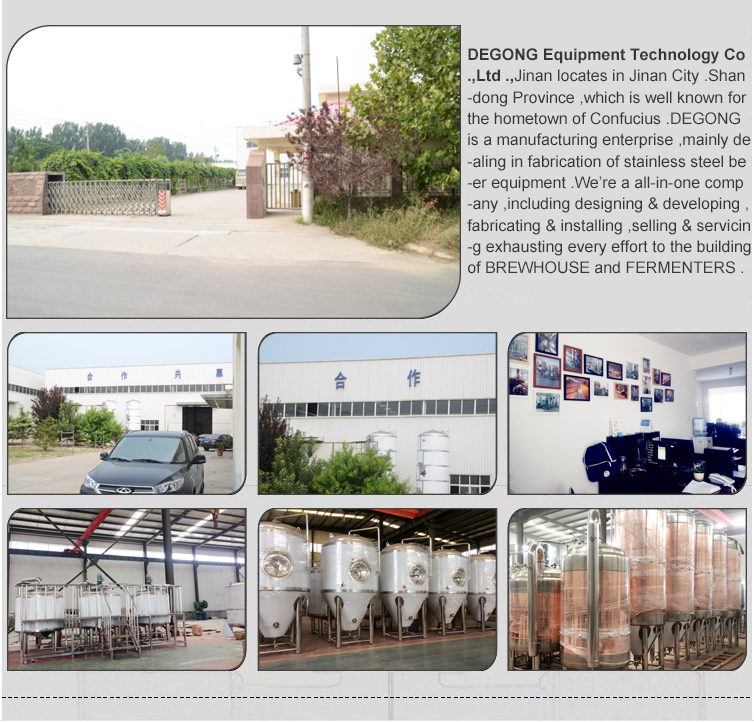

Our factory

Application

Packing&Logistic

We have obtained TUV ceritification,which is issued by Germany institution

Guarantees:

All the materials touching with beer directly are all top quality food grade stainless steel

We use the first class valves and manhole for our equipments

All the materials I use is nonmagnetic.

The thickness of the material exact fit in with what shown in our quotation sheet

Most importantly,Our staff is always available for your needs and questions.

After-sale services:

Within the warranty period, any malfunctions caused by the quality issues or material issue, Degong will be responsible to it.

After delivering the equipments to our customers, Degong will arrange special worker to do the track service,because we set up the marketing department for specially dealing with the feedback of customers for providing the satisfied service. Once Degong gets the feedback from customers, we will do our best to deal with it for you.

For the malfunctions beyond the warranty period, Degong will also be responsible to it, but the seller should take in charge of the expenses.

Degong can dispatch technicians to install the equipments for you, but the seller should take charge of the expenses.