Description

200L Mini Microbrewery is a set of technical equipment used to produce “fresh” and filtered beer. The brewing master makes beer attractive to consumers through unique brewing technology and unique beer taste. Many customers ask about home breweries, but they are not sure about the required capacity. The 200-liter beer brewing equipment is low cost and small in size. Suitable for brewing beer at home. In addition to stainless steel, interpreters may also face polished brass and copper. Similarly, if you want to put it in a brewery, so that visitors can observe the beer brewing process. This is an excellent internal design solution and a powerful marketing tool.

500L beer brewhouse equipment(3 vessel)

500L beer brewhouse equipment(3 vessel)

200L Mini Microbrewery brewhouse more information

- Material:Inner(SUS304),thickness:3.0mm

- External-Jacket(SUS304),thickness:3.0mm

- Cylinder(sharp type,SUS304),thickness:3.0mm

- Inner surface treatment :weld grindede to Ra 0.6μm

- Insulation: Polyurethane-thickness 100mm

- Temperature way: Double metal thermometer

- Outsourcing surface: Weld polishing processing

- Jacket Pressure:design pressure 0.3 MPa,working pressure <0.2MPa

- CIP 360 degrees Omni bearing cleaning

- Wort pump:Stainless steel 304 food

- Plate Heat exchanger:Completely 304SS corrugated plates

- Operation platform: Platform frame is constructed entirely of stainless steel with a stainless steel diamond plate deck.A stainless waterright electronics enclosure is mounted to the back of the platform.Stairs are constructed of stainless steel diamond plate deck material.

- Brewhouse details: side manhole, spent grain hatch, ABB motor, butterfly valves, PT-100, sight glass, raker, food grade pipe, leg and adjustable foot.

200L Mini Microbrewery brewhouse details

200L Mini Microbrewery brewhouse details

200L Mini Microbrewery fermentation tank more information

- Interior Shell: SUS304 full welded; TH=3mm

- Exterior Shell:SUS304 full welded; TH=2mm

- 100% TIG welding with pure argon gas shield

- Interior Finish: Overall polishing to 0.6 μm without dead corner

- Glycol Jacket: Dimpled plate on cone and side

- Stringent tank leakage test by water and pressured gas

- Stringent Jacket leakage test by water and pressured gas

- Dished head and 60 degree cone bottom

- Sanitary top mounted manway

- CIP arm with 360° coverage CIP spraying ball

- Full sanitary sampling valve

- Mechanical relief valve 2 bar on CIP arm

- Shockproof pressure gauge on CIP arm

- Rotating racking arm and port on cone with butterfly valve

- Tri clamp discharge arm with butterfly valve

- Thermowell for high accuracy temperature sensor

- 3pcs completely SUS304 heavy duty legs with leveling pad and legs support

- Complete valves, fittings and all parts

- Level tube for special request

- Carbonation port and stone for special request

200L Mini Microbrewery fermentation tank details

200L Mini Microbrewery fermentation tank details

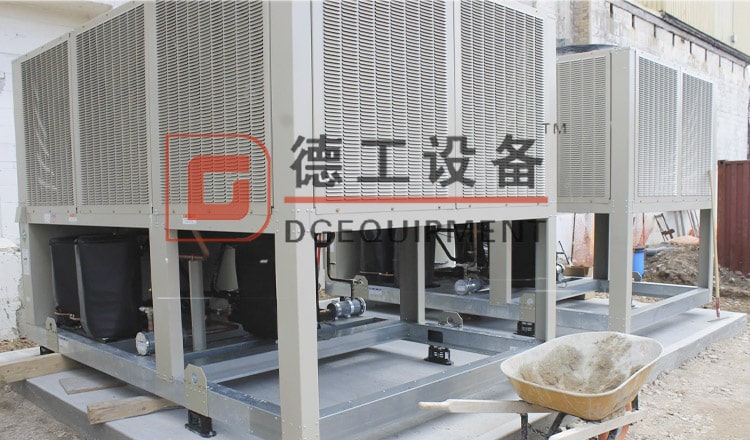

Chiller(refrigeration unit)

Chiller(refrigeration unit)

Bright beer tank front view and back view

Bright beer tank front view and back view

DEGONG advantage

If you want to order beer brewery equipment, please contact me now! Thanks.