Description

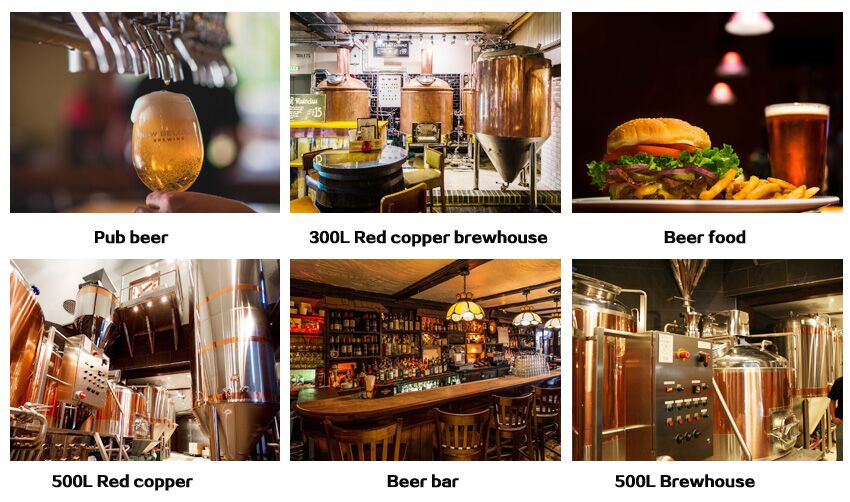

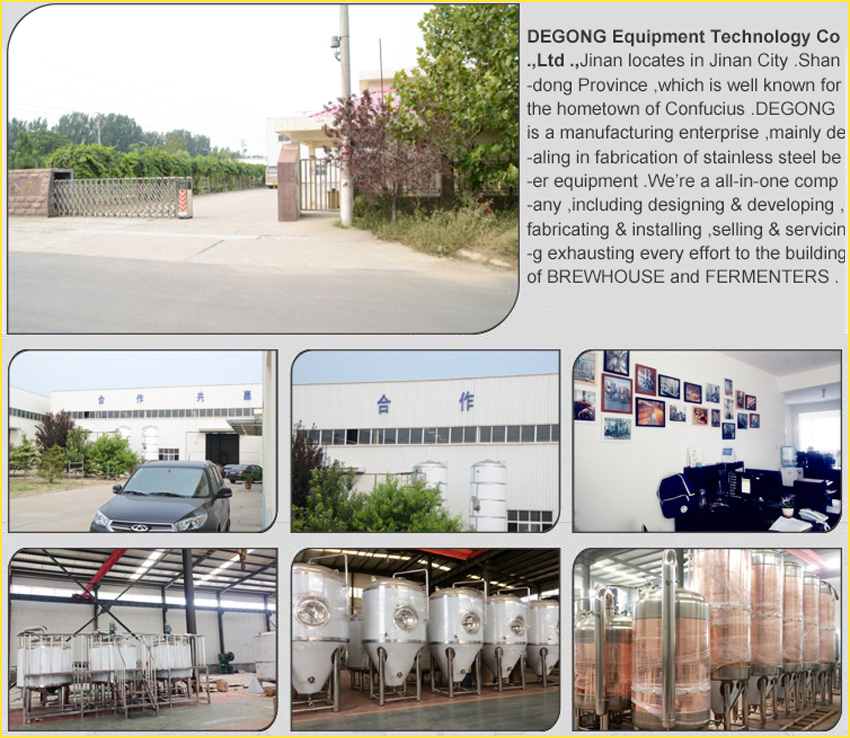

Beer fermenter/Unitank is for brewing beer. Conical beer fermenter has the cone-shaped bottom that is for allowing the yeast slipping down easily. Different customers have different requirements on the design of fermenters. So we are open for your thoughts before manufacturing. The warranty period is 2 years, we will in charge of every natural malfunction occurred within this period. We’ve got many sales agent around the world for you as the customers reference. We always take the state of the art workmanship to build the equipments according to your requests. The capacity varies from 50L to 20000L. We aim for your success!

Industrial jacketed beer fermentation tank/Unitank

- Design pressure: 3bar (45 psi)

- Working pressure: 1.5-2bar (21-29 psi)

- 4 stainless steel feet with leveling feet

- Inner shell: stainless steel 304 Thickness:3.0mm

- Outer shell: same as above 2.0mm

- Jacket: same as above 1.5mm

- Mirror polishing interior; Welds are ground to Ra0.6μm

- Dished head top and bottom, 25% head space

- With side manway

- Dual cooling zone at the cylinder and bottom

- Insulation: polyurethane(PU) Thickness: 100mm

- Spraying ball and CIP arm

- Perlick style sample valve

- Carbonation stone port(optional)

- Temperature probe and pressure gauge

- All necessary components are included, such as valves, lifting lugs, mechanical regulation valve, etc.. (Solenoid valve can be purchased as your desire)

- Certificated sanitary food grade SS304

- High quality valves & components

- Dual cooling areas which is easy to operate and good for saving energy

- At least 25 years using life

- Easy to maintain, operate. Saving time and labor

- All fermentation tanks should pass the tank leakage test before leaving our factory

- Carbonation stone port for special use

- With dry hopping at the top

- Fine welding seams treatment

- More economical and competitive

- Completely customizable as requested

- CE, ISO, TUV approval

- With tubular level meter for special use

- Novel structure and attractive appearance

- More humanized design

- All the materials touching the beer directly are all top quality food grade stainless steel.

- We use the first rate valves and manholes for all our equipments.

- I am here to guarantee all our customers that the materials are nonmagnetic.

- The thickness of the material exactly fit in with what showed in the specification sheet.

- If you are a new comer to the beer making field, Don’t worry, I will give you our professional recommendations. And the equipment must be top quality engineered.

- Engineer is always available to make the relative 2D and 3D drawings for you for your reference.

If you want more info of the equipment, contact me directly via:

WhatsApp/Tel:+86 15863177821

Skype:swift05

Email: [email protected]