Description

Description of 1000L commercial micro beer brewing equipment |

A complete set of 1000L micro beer brewing equipment

1000L micro beer brewing equipmet is consisted of 6 main systems which are respectively malt milling system, brewhouse system, fermentation system, cooling system, CIP system and control system. Our micro beer brewing equipment is custom built based on customers’ specific requirements to fit their different needs. Brewhouse system and fermentation system are customers’ most concerned two points. So I am going to introduce the brewhouse system and fermentation system here.

Brewhouse system of 1000L micro beer brewing equipment |

Brewhouse system can be 2-vessel, 3-vessel or 4-vessel which depends on customer’s expected beer output. For 1000L beer brewhouse system, 3-vessel is the most used one as it can not only meet the need of brewing 2 batches per day but also is a relatively economic option for beginners. 3-vessel brewhouse refers to mash/lauter; kettle/whirlpool; hot water tank. Anyway, it is not fixed, customers is allowed to change the structure.

Mash/Lauter of micro beer brewing equipment:

- Stainless steel material

- VFD raker system

- Laser cut false bottom

- Thickness of inner shell: 3.0mm; outer shell: 2.0mm; Jacket: 1.5mm

- ABB/ Siemens motor

- Side manhole for discharnging spent grain automatically

- Tempered glass top manhole

- 4 pcs of heavy duty stainless steel legs with leveling footpads

- CIP arm with spraying ball of 360 coverage

- Backwater flushing system

- Insulation: Polyurethane

Kettle/Whirlpool of micro beer brewing equipment:

- Stainless steel material

- VFD Blender system

- Tangential wort inlet

- Thickness of inner shell: 3.0mm; outer shell: 2.0mm; Jacket: 1.5mm

- Steam jackets on cone and body

- Tempered glass top manhole

- 4 pcs of heavy duty stainless steel legs with leveling footpads

- CIP arm with spraying ball of 360 coverage

- Insulation: Polyurethane

Hot water tank of micro beer brewing equipment:

- Stainless steel material

- Thickness of inner shell: 3.0mm; outer shell: 2.0mm; Jacket: 1.5mm

- Steam jackets on cone and body

- 4 pcs of heavy duty stainless steel legs with leveling footpads

- CIP arm with spraying ball of 360 coverage

- Insulation: Polyurethane

Fermentation system of 1000L micro beer brewing equipment |

Fermentation tank is where fermentation process occurs. There generally are two reactions when fermentation is happening. First is aerobic respiration, followed by anaerobic respiration. The beer after the fermentaion process is drinkable.

Fermentation tank of micro beer brewing equipment:

- Stainless steel construction

- 100% TIG welded with argon gas protection

- Thicness of inner shell: 3.0mm; outer shell:2.0mm; jacket:1.5mm

- Design pressure: 0.3MPa

- Working pressure: 0.15-0.2MPa

- Insulation: Polyurethane

- 4 pcs of heavy duty stainless steel legs with leveling footpads

- Side manhole

- CIP arm with spraying ball of 360 coverage

- Glycol jackets on cone and body

Components:

- Pressure relief valve & vacuum valve

- Dry hopping hole

- Pressure gauge

- Pressure bunging device

- Side manhole

- Sample valve

- Temperature sensor

- Thermowell

- Themometer

- Racking arm

- Drain with valves

- Glycol jackets with inlets and outlets

Certificate of our micro beer brewing equipment |

Our beer brewing equipment is approved by UL, CE, ISO, TUV.

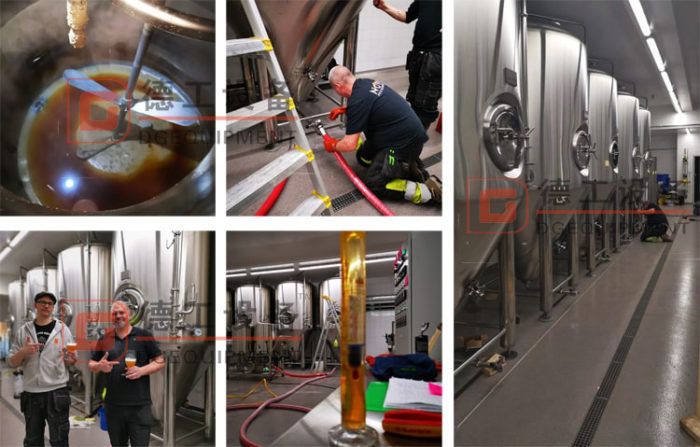

Customers reference |

Why choose us |

-

Our company’s advantages

We have a modernized standard factory and employ more than 100 employees. Our company is a high-tech enterprise which combines design, developing, selling and after-sale service as a whole.

-

Our company’s quality certification

We have got CE, PED, UL,ISO9001 (2008) and SGS certificates for our micro beer brewing equipment. If necessary, we can offer electronic record’s certificates but the original document must be kept in the company.

-

Our company’s customer

Our customer segmentation is mainly focused on the Euramerican developed countries such as the USA, Canada, the United Kingdom, Australia and Russia, etc.

-

Choose us and get more benefits

Deliver innovative products in the market at a faster pace;Enhance the reliability of product’s quality;Decrease the total cost of the product effectively; Improve research personnel’s ability of creative design.

Contact us |