Description

1000L-SUS304 stainless steel brewing system

The 1000L beer fermenter future:stainless steel, vertical, double-walled, insulated, 60 degree cone bottom, dished head, beer fermentation tank.Cylindrical and conical parts have independent glycol cooling zones controlled by temperature sensor.

Suitable for brewpubs / restaurants and craft breweries / beer production. Includes malt plants, heating, control, installation, training and beer recipes. You can produce excellent rich beer. Beginners will find it easy to brew using this fairly automated device.

beer fermenter

1000L beer fermenter

- Stainless steel 304 sanitary construction

- 100% TIG welded and sanitary polished

- Design pressure is 0.3MPa,using pressure is 0.15MPa

- 4 heavy duty stainless steel legs with adjustable height and leveling footpads

- Interior:stainless steel 304,thickness 3mm

- Interior treatment:Mirror polishing

- Outerior:stainless steem 304,thickness 2mm

- Jacket:stainless steel 304,thickess 1.5mm

- Insulation:80mm Polyurethane

- 60 degree conical bottom

- Heat exchanger area:5.89m2

- Side mahole

- Lifting ear

- Temperature sensor

- Pressure guage

- Machinery regulator

- Breathing valve

- Hops adding hole

- Simple valve

- Raking arm

- Valves&fittings

- Add carbonation stone

Packing&Logistic

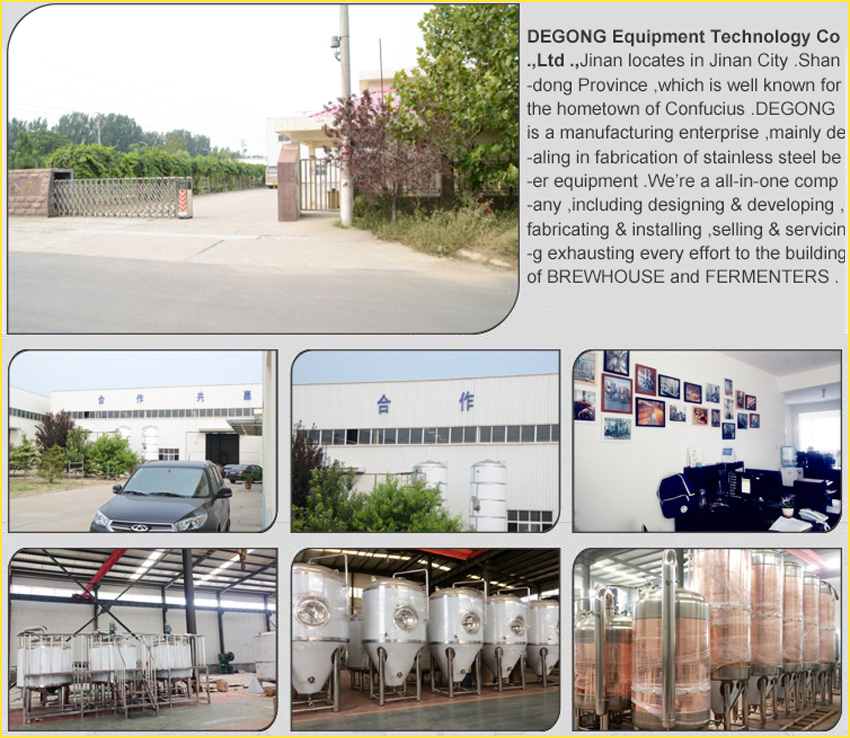

Our engineer go to Visit customer’s brewery and explore brewing technology

We have obtained TUV ceritification,which is issued by Germany institution

Guarantees:

- All the materials touching with beer directly are all top quality food grade stainless steel

- We use the first class valves and manhole for our equipments

- All the materials I use is nonmagnetic.

- The thickness of the material exact fit in with what shown in our quotation sheet

- Most importantly,Our staff is always available for your needs and questions.

After-sale services:

- Within the warranty period, any malfunctions caused by the quality issues or material issue, Degong will be responsible to it.

- After delivering the equipments to our customers, Degong will arrange special worker to do the track service,because we set up the marketing department for specially dealing with the feedback of customers for providing the satisfied service. Once Degong gets the feedback from customers, we will do our best to deal with it for you.

- For the malfunctions beyond the warranty period, Degong will also be responsible to it, but the seller should take in charge of the expenses.

- Degong can dispatch technicians to install the equipments for you, but the seller should take charge of the expenses.

If you have interest to know more details,please get in touch wiht me freely.