Description

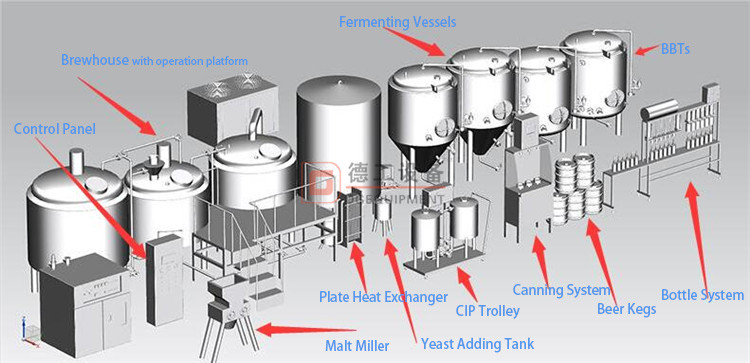

Industrial breweries and microbreweries plants that produced by DEGONG equipment technology Co.,Ltd.These breweries performed in 5 HL/batch – 50 HL/batch in turnkey solution according to customer location and special project planning.Industrial breweries configurations designed for multi process operations, ensures a wide range of beer types manufacturing by using all brew technology types, that makes the breweries universally useful.

You also can order any brewery capacity as 1500L, 2000L, 3000L, 3500L, 4000L, 4500L,5000L and etc. according to your needs.

1500L stainless steel customized food grade beer brewing equipment for sale

Two-vessel brewhouse is most widely commercial-used and with high performance-price ratio.The system can be heated by steam,electricity or gas;and controlled by manual,semi-automatic or full automatic.

Standard configuration for 2-vessel brewhouse system includes 2 brewhouse vessels:mash/lauter tun and kettle/whirlpool combined vessel,work platform,and stainless steel sanitary piping and control system.

Mash/lauter tun combined vessel typical features:

Top manway,CIP spray ball,top sparging system,port for grist hydrator,vapor vent port,gear drive and rake system.False bottom removal slot,thermowell port,rectangular side manway .Wort out collector,false bottom,spent grain-out port.

Kettle/whirlpool combined vessel typical features:

Top manway,CIP spray ball,top sparging system,vapor vent port on the top; Tangential whirling port,side steam jackets;thermowell port,wort out port;bottom steam jackets;or gas burning room for gas kettle

Piping system includes all internal connected pipes for the brewhouse,i.e.:wort piping,sparging piping and CIP piping;also includes the necessary functional assemblies,such like liquor blending system with flow meter,and wort aeration with sterile air filter;and the auxiliary equipment,such like wort pump(s)and heat exchanger;and all fitting,valves and devices in the pipes.Brewhouse pipes material is 304 sanitary stainless steel.

| Dimension | Brewhouse | Fermentation tank | Beer bright tank | Glycol tank |

| 500L | 1060*1900 | 960*2200 | 960*1850 | 860*1700 |

| 1000L | 1400*2500 | 1300*2550 | 1300*2100 | 1260*1900 |

| 1500L | 1600*2550 | 1400*2900 | 1400*2300 | 1500*2000 |

| 2000L | 1600*2900 | 1500*3300 | 1500*2550 | 15000*2450 |

| 4000L | 2100*3100 | 1800*3950 | 1900*3100 | 1900*2750 |

beer brewing brewery equipment details

beer brewing brewery equipment details

Fermentation tanks main features:

Material:SUS304

Interior thickness:3mm,Exterior thickness:2mm,Insulation:polyurethane 100mm

Cylinder and cone 60 degree

Top or side manhole

Working pressure: 1.5-2.0 bar

Design pressure: 3.0 bar

With electromagnetic valve, mechanical regulating valve,breathing valve,sample valve,temperature sensor, pressure gauge,hops add hole,carbonation stone,adjustable leg,cooling jacket

Our exhibition

If you would like to a quotation,please contact me at any time.