Description

| Customized brewery beer tanks |

DEGONG Micro brewhouse is a compact, universal stainless steel system for brewing all types of beer, from light to lager.

The brewhouse assembly consists of six main vessels,a frame, staircase, service platform, railing, control panel, wort cooler as well as mash, wort, cold and hot water pumps. Different technological parts of the brewhouse are linked by stainless steel piping and all the necessary valves, flow meters, sight glasses, lighting, etc. The system enables both infusion and decoction brewing methods; it is intended for demanding customers and for industrial beer making.

Copper brewhouse system made in manufacturer China

6-vessel Brewhouse consist of :

Brewhouse – Mash tun

For mash mixing and mashing processes supported by mash stirrer.

Brewhouse – Lauter tun

For the gravitational lautering of mash and malt wort extraction. The tun is equipped with rake arms with speed adjustment and reverse running features.

Brewhouse – Kettle

For the wort boiling process.

Brewhouse – Whirlpool

For separation of sediments from wort.

Brewhouse – Hot water tank

For the preparation of hot water for the boiling process and collection of heated water from the wort cooler.

Brewhouse – Cold water tank

For the preparation of cold water for the wort cooling process preceding wort conveyance to fermentation tanks.

Brewhouse system and its components,likesight glass,rakers;false bottom;pumps

Put the hops in the boiling tank/kettle

Each brewing unit is unique in its own way and optimally designed with the technical solution of the required beer brewing technology in accordance with ideas of the customer respecting all hygienic and safety regulations as well as standards at the country of destination. Installation of the equipment at the customer’s site includes commissioning based on beer wort test brew followed by inoculation in the fermentation tank; and training of staff for smooth operation of the brewing unit to be handed over.

We are perfectly familiar with technological requirements of beer brewing, and so we can provide our customers with reliable equipment that will enable them to obtain a quality end product – beer with top quality body and full flavor.

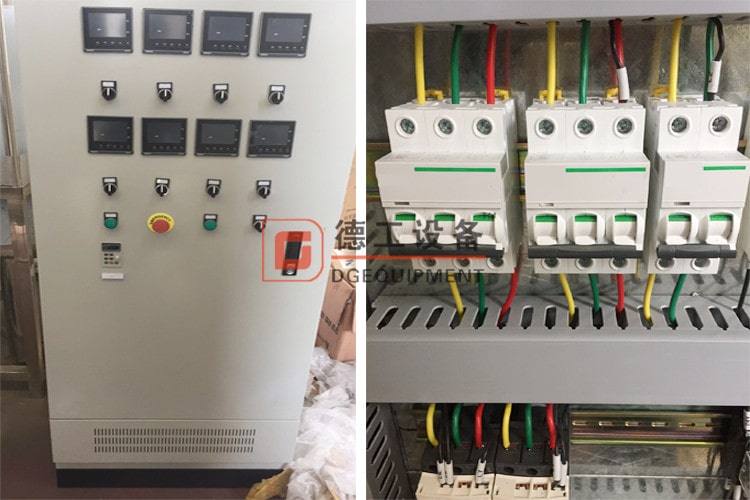

Semi-automatic control panel for brewhouse and fermenting

Control panel

It includes a control panel and an electrical box assembly.The system is semi-automatic.

- Variable speed drives

- Grist conveyor control

- Variable mash and wort pump speed

- Variable mash agitator and rake arm speed

- Brewhouse lighting controls

- Kettle and hot water tank heating controls

- Brewhouse tank temperature controls

- An emergency shutdown switch

Brewhouse apply to restaurant,brewpub,hotel

| Contact Alice today |

Talk to us about your requirements and we will design a system to work for you and your company.