Description

Brewing system China available for small, medium and large

| Brewhouse equipment features: |

Breweries have classic packaging arrange consisting of brewing kettle,fermentation vessels and additional equipment.The brewery equipped with semiautomatic control panel.Staff training occurs during installation of equipment and test brews.

2 vessel brewhouse stainless steel beer brewing system with a hot liquor tank

Why use a DGET Brewhouse for Brewing?

- DGET brewhouses offer thoughtfully designed equipment that make brewing easier. Our commercial line of kettles are designed for high efficiency and and our commercial line of mash tanks are loaded with features which simplify maintenance and are designed for ease of use.

- Each of our brewhouses includes control system, brewing platform, water blending, pumps, heat exchanger, and all piping.

- Customizations are easily possible, and we make every effort to make sure the systems conform to any unique processes you might have in your production.

Stainless steel beer brewing system

False bottom & wort pump & stainless steel platform & sight glass

1- Mash / Lauter Tun

Used to combine grist and hot water. A false bottom is then used to extract the clear wort from the malted barley. The spent grains left over can be used for animal feed.

2-Brew kettle / Whirlpool

The wort is boiled to a desired specific gravity and hops are added for flavor and bitterness. After boiling the wort is whirlpooled to collect soluble proteins in the center of the kettle. The clear wort is then pumped through the heat exchanger and into the fermenter.

3-Hot Liquor Tank

Used to recover energy and heat the water (liquor) needed for recirculation and sparging water onto the grain bed to convert starches to sugar.

4-Transfer Pumps

Pumps transfer liquid flow from the mash / lauter tun to the kettle and then onto the fermenters. Designed with one person ease of use and cleaning in mind.

5-Heat Exchanger

Using city water and/or cold glycol as cooling mediums the wort is cooled to acceptable fermentation temperature,before it goes to the fermenter.

| Brewery plant brew house unit | |

| Mash/Lauter Tun | Grain rake for uniform mashingGrain out door with grain chute

Laser cutting false bottom Grist hydrator for optional Steam jacket for optional |

| Kettle/Whirlpool Tun | Steam, electric, or direct-fired for heating optionalSteam condenser

Tangential whirlpool inlet Insulation layer 100mm |

| Hot Liquor Tank | With dimple jacket |

| Brewhouse Ancillary Equipment | Malt millerHeat exchangerWork platform and more |

Stainless steel beer brewing system

Sight glass;raker;spent grains hatch with chute

| Fermentation system features: |

Beer fermentation tank or CCT, fermenters will profuce beer for fermentation and maturation. We design, manufacture all variety fermenters from 100L to 30000L . With all the necessary valves, connections, microbrewery fermenters are the CE certification.

2000L stainless steel beer brewing system fermentation tanks display

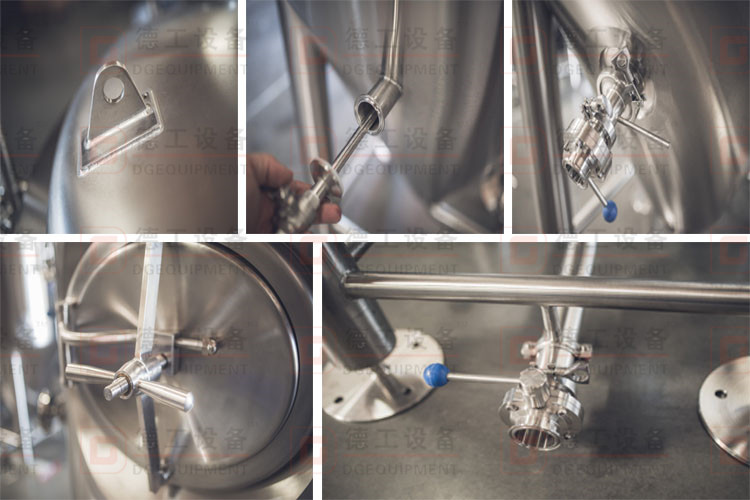

Cylindro-conical tank Features:

- All connections are fully welded Tri Clamp fittings

- 0.12 -0.15Mpa operating pressure; 0.3Mpa design pressure

- Pressure gauge

- Versitile port for dry hopping, CIP, and the pressure relief valve

- Sampling valve

- Thermowell for thermometer

- Carbanation stone

- Blow off cane,ball valve

- Polyurethane insulation jacket 100mm

- Custom ss butterfly valves with racking arm

- Stainless lower shelf

- Adjustable feet

- Made from 304 stainless steel

Fermentation tank Racking arm;side manhole;drain outlet

Control cabinet for mashing,fermenting

| DGET introduction: |

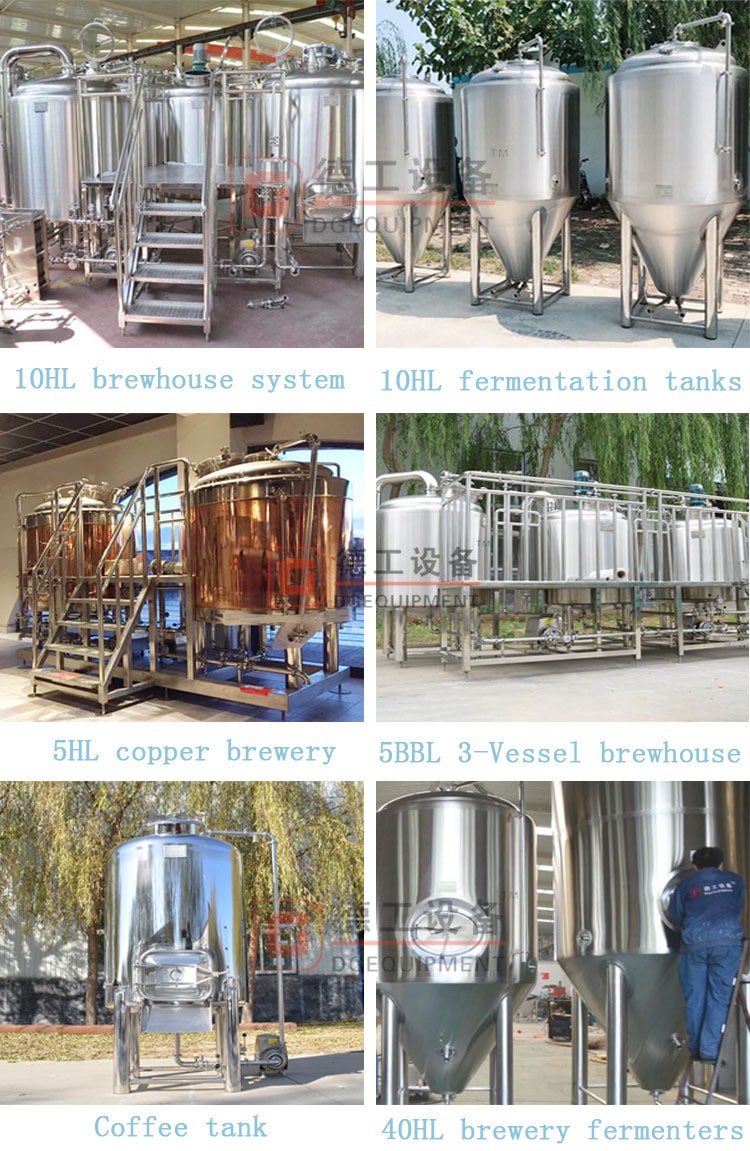

Related Products display:

Our services:

- Design: DG engineers is providing various types of brewing design services according to cutomers’ requirements.

- Testing and Maintenance: professional equipment and application product testing and maintenance services according to actuall working conditions.

- Project Evaluation: this assessment includes all the elements of in mind project including advantage, technology, efficiency, quality control etc.

- Continuous Service: actively provide pre-sales, sales, after-sales service and value-added services to help customers enhance value.

| Contact information: |

Talk to us about your requirements and we will design a system to work for you and your company.