Description

| 1000l Brewing System for craft beer |

The importance of malt in brewing

Malt provides:

- enzymes and starch for the production of alcohol and carbon dioxide;

- organoleptic compounds that determine the beer’s flavor profile;

- color, based on the intensity of the chemical reaction during kilning;

- and proteins, which boost yeast activity and provide body.

Brewhouse tanks with double size hot water tank brewing system

Bright beer fermentation tanks brewing system

Fermentation tanks, or more commonly fermenters, are key components in beer and kombucha brewing. Fermenters are specialized tanks designed to precisely control temperature and maintain the optimal conditions for fermentation, which occurs once the wort has been transferred from the brewhouse to the fermenter; a conical-bottom design is highly recommended for fermenters allowing for easier yeast harvesting.

Fermentation Tanks provide the brewer with several key advantages:

Every fermenter with a ultimate drain and 60 degree conical bottom for rapid and easy yeast harvest and clean-out

Precision laser welded dimple jacket with integrated baffling, reduces glycol demand and increases tank efficiency by 25%

A worldwide reputation for industry leading design, engineering, and fabrication

Insulated vessels add efficiency, minimize heat-loading, and reduce safety hazards

Made of 100% non-reactive, sanitary-finished, 304 food-grade stainless steel

Innovative design registers zero stress on the internal structure of the tank

Integrated Clean in Place (CIP) systems allow rapid and convenient cleaning

Manufactured process maintains the highest standards of quality throughout fabrication

Every fermenter is equipped with:

- racking arm

- pressure relief valve

- blow-off/ clean-in-place (CIP) tube

- CIP spray ball

- sample valve

- butterfly valves

- TC clamps, gaskets and clamps

- 90-degree elbows

Fermentation tanks brewing system model

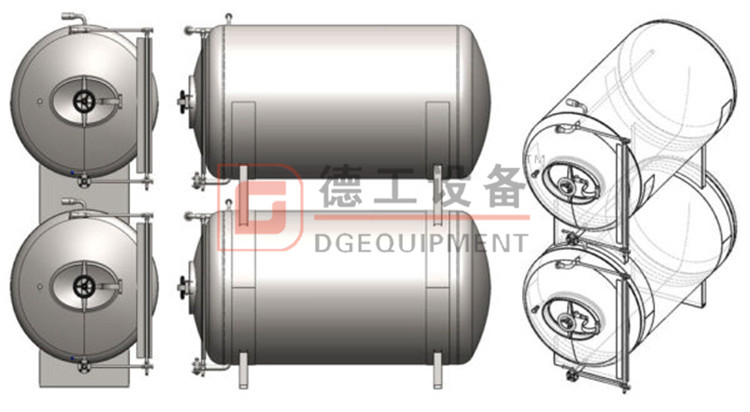

Horizontal beer brewing system maturation tanks

Basic configuration:

● Grain handling: hand or electric malt mill

● Brewhouse: Two or three vessels, gas, electric or steam heating

● Cellar: Fermenter/unitanks or BBTs(Optional), pre assembled piping line on platform

● Cooling: Chiller with glycol reservoir or connected with existing big brewery

● CIP: movable pump for either tank cleaning or beer transfer

Features:

● Simple but perfect solution to guarantee stable beer quality

● Easy to move and assembly

● Compact system or being installed on platform

● Well pre assembled system for easy installation and transportation

● Well suits the local authority regulation

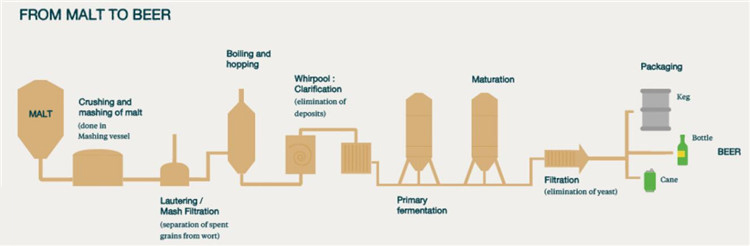

From malt to beer

| Contact Alice today |

Talk to us about your requirements and we will design a brewing system to work for you and your company. wlcome to consult brewery to get a perfect quotation.