Description

Description of 1000L 2/3/4 vessel beer brewery equipment for sale

1000L stainless steel beer brewery equipment

1000L high quality beer brewery equipment, as one of the best selling brewery equipment in my company, has been sold to every corner of the world by far, including Ireland, UK, Switzerland, Sweden, Germany, Belgium, Chile, USA, etc… What we provide is not only high quality beer brewery equipment, but also passion and techniques for beer brewing. We are more than happy to help you througout the process from design of beer brewery equipment to delivery. What’s more, our brewery equipment can be made according to customers’ specific requirements.

Main components of 1000L beer brewery equipment

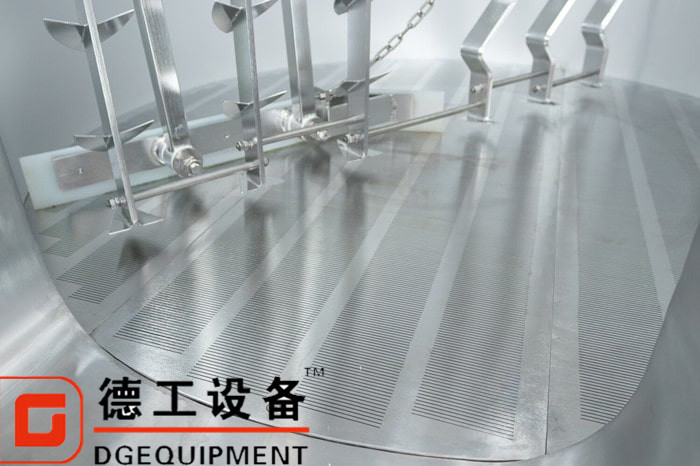

Mash/Lauter tun:

- Stainless steel grist hydrator

- Upper and lower jackets (Just for steam heated system)

- CIP spray nozzles under false bottom

- Fully insulated tank

- Stainless steel material

- SS CIP high low rotary spray ball with 360 of coverage

- Interior light

- Sparge ring assembly

- Tempered glass top manhole

- Side manhole for automatic spent grain out process

- Automatic variable speed rake system and spent grain plow

- SEW motor for rake system

- Laser-cut falst bottom

- Thickness: inner=3mm; outer=2mm; jacket=1.5mm

Kettle/Whirlpool tank:

- Upper and lower steam jackets

- Tangential wort inlet

- Fully insulated vessel

- Stainless steel material

- SS CIP high low rotary spray ball with 360 of coverage

- Interior light

- Tempered glass top manhole

- Thickness: inner=3mm; outer=2mm; jacket=1.5mm

- Thermowell assembled with RTD for sensoring the temperature inside the tank

Wort pump:

- VFD speed control

- Stainless steel sanitary pump

- 3ton/hour

Control cabinet:

- Control the temperature of each brewhouse tank

- Control on/off of the motors of raker and blender

- Control on/off of steam solenoid valves

Working paltform:

- Made out of stainless steel

- In accordance with European standard

Heating exchanger:

- 1 stage or 2-stage type

- Connected with sight glass, Venturi pipes, etc…

Beer fermentation tank of 1000L brewery system

- 100% TIG welded with sanitary polished

- 4 pcs of heavy duty stainless steel legs with leveling footpads

- Thickness: inner=3mm; outer=2mm; jacket=1.5mm

- Design pressure: 0.3MPa

- Working pressure: 0.15-0.2MPa

- Dual zone cooling jackets

- Interior (2B) and exterior finish bright polish, sanitary surface

- Tri clamp sanitary fittings

- Pressure relief & vacuum valve

- Dry hopping hole

- Pressure gauge

- Pressure bunging device

- Side manhole

- Temperature sensor

- Thermowell with RTD sensor

- Sample valve

- Racking arm

- Drain with butterfly valves

Certificate

Our company has obtained CE ISO TUV certificate for our beer brewery equipment

Why choose us

- Our company’s advantages

We have a modernized standard factory and employ more than 100 employees. Our company is a high-tech enterprise which combines design, developing, selling and after-sale service as a whole.

- Our company’s quality certification

We have got CE, PED, UL,ISO9001 (2008) and SGS certificates. If necessary, we can offer electronic record’s certificates but the original document must be kept in the company.

- Our company’s customer

Our customer segmentation is mainly focused on the Euramerican developed countries such as the USA, Canada, the United Kingdom, Australia and Russia, etc.

- Choose us and get more benefits

Deliver innovative products in the market at a faster pace;Enhance the reliability of product’s quality;Decrease the total cost of the product effectively; Improve research personnel’s ability of creative design.

Customers reference:

Where you can use the 1000L beer brewery equipment: