Description

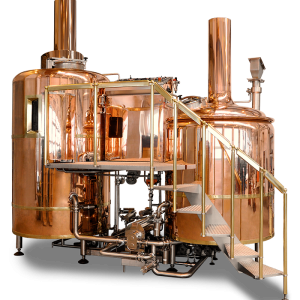

1000L stainless steel industrial beer making machine customized brewhouse equipment

|

2-vessel brewhouse |

2-vessel brewhouse configuration offer brewers a simple and cost effective solution. Through combining mash tun & lauter tun, and kettle & whirlpool into a 2-vessel solution, it will help you on space and cost saving without compromising brewing quality and control. |

|

3-vessel brewhouse |

3-vessel brewhouse configurations offer brewers a more efficient and faster brewing solution and achieve multi temp. control for step mash. It can be comprised by mash/lauter, kettle/whirlpool, and hot water tank. |

|

4-vessel brewhouse |

4-vessel brewhouse configuration offer brewers a professional and higher performance brewing solution for multi batches brew per day. It is comprised by mash, lauter, kettle, whirlpool. DG’s 4-vessel brewing system offer you options of semi-auto or automation controlling and overall flexibility. |

Features:(brewhouse equipment)

a.inner thickness:sus 304,3mm

b.outer thickness: sus 304,2mm

c.jacket:sus 304,1.5mm

d.insulation:polyurethane 100mm

e.inner sueface treatment:welds grinded to Ra 0.6um

f.outsourcing surface:weld polishing processing

g.jacket pressure:design pressure:0.3Mpa,working pressure:0.12-0.15Mpa

Our survice:

1.Design: DG engineers is providing various types of brewing design services according to cutomers’ requirements.

2.Testing and Maintenance: professional equipment and application product testing and maintenance services according to actuall working conditions.

3.Directed: transforms demand into the latest solutions and products with our advanced technology to help clients build core competitiveness.

4.Project Evaluation: this assessment includes all the elements of in mind project including advantage, technology, efficiency, quality control etc.

5.Continuous Service: actively provide pre-sales, sales, after-sales service and value-added services to help customers enhance value.

6.Training and Improvement: carries on the thorough training to the user, in order to maximize the equipment and the product functions.

Quality control:

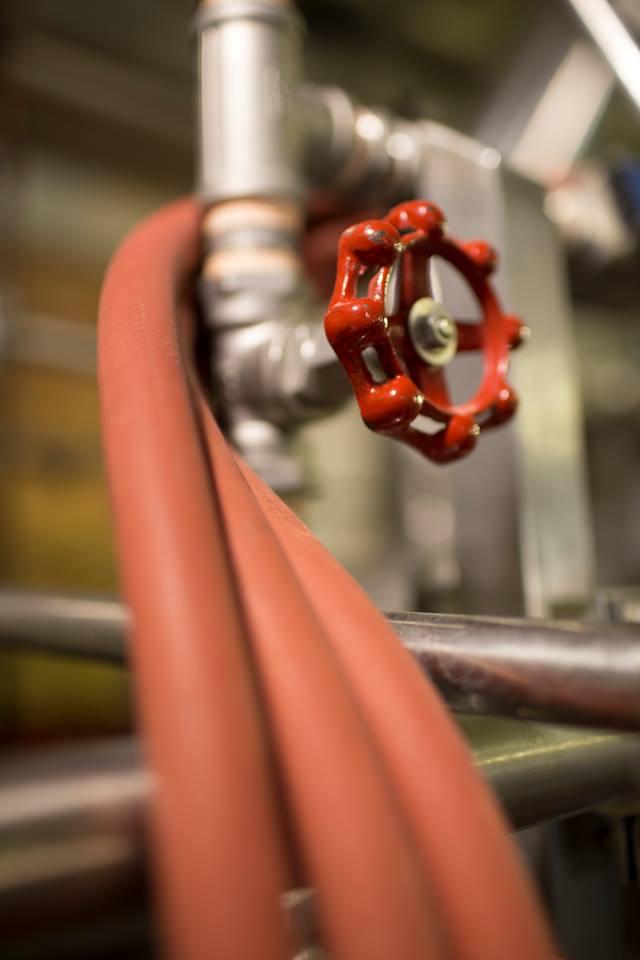

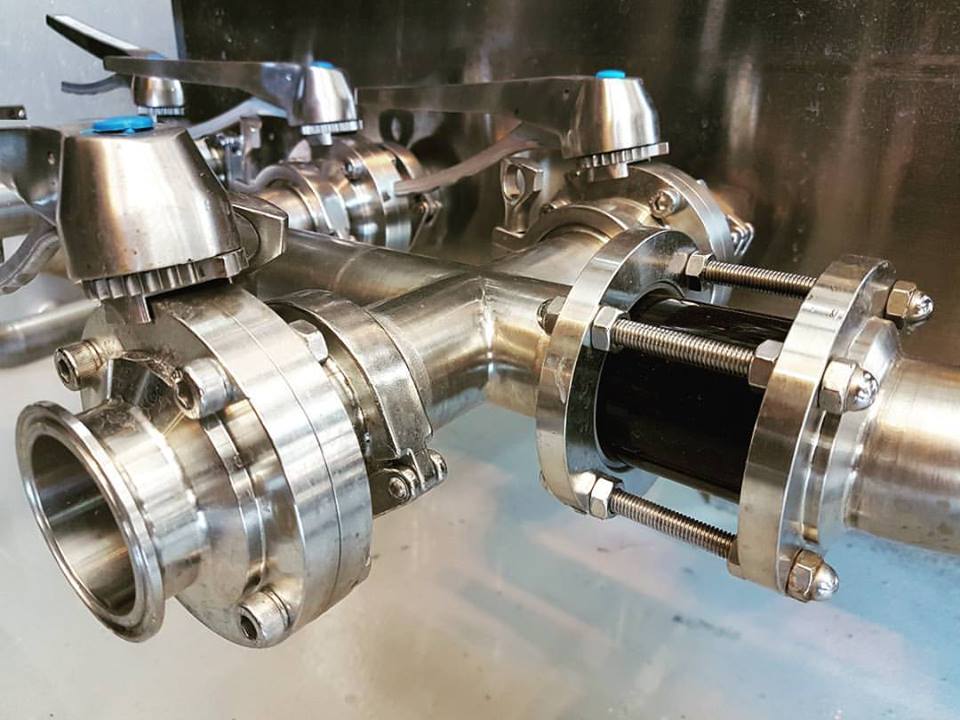

1. Construction by high quality SUS 304 food grade stainless steel, all pipes are SUS 304.

2. All tanks will be tested and detected in the NDT room after finished, to ensure no leakage.

3. All jackets will do water and pressure testing, design pressure: 3bar, working pressure: 1.5-2bar;

4. All tanks will be pressure protection 48 hours before leaving from factory;

5. All the welds are TIG full welded, dimpled jacket by using water to weld to make sure uniform to be long life.

6. All tanks are mirror polishing inside without dead corner, welds grinded to Ra 0.4um.

7. All the manholes and clamps gaskets will be sanitary.

Our factory:

Application:

Contact information: