Description

2000L stainless steel beer brewery line with three vessels steam heated brewhouse

The 2000L beer brewery line is made for a Sweden customer.The brewhouse is 3 vessels brewhouse(mash/lauter tank,boiling/whirlpool tank and hot water tank) with bottom agitator.The pumps,agitator,raker will be controlled by VFD.The componont of the control panel is Siemens,Omron,Schenider,and it is accord with TUV standard.All of the material is food grade stainless steel 304.

Specifications of 2000L beer brewery line:

SUS 304/SUS316/Copper clad,Inner Thickness=0.3mm,Outer thickness=0.2mm

Optional heating style of steam, electric and direct fire for brewhouse tanks

Internal 2B finishing, welds polishing to 0.4um

Cylindric and bottom with steam jacket–Max 3 bar pressure ensures 1°C/min heating speed.

PLC control panel with Siemens,Omron,Schenider element,and accord with EU standard

VFD controlled reducer and wort pump

Assembly sanitary rotary spray balls for cleaning

PU insulation,thickness:100mm

Temperature sensor(RTD) in a thermowell

Rake and mash agitator assembly with top/bottom reducer

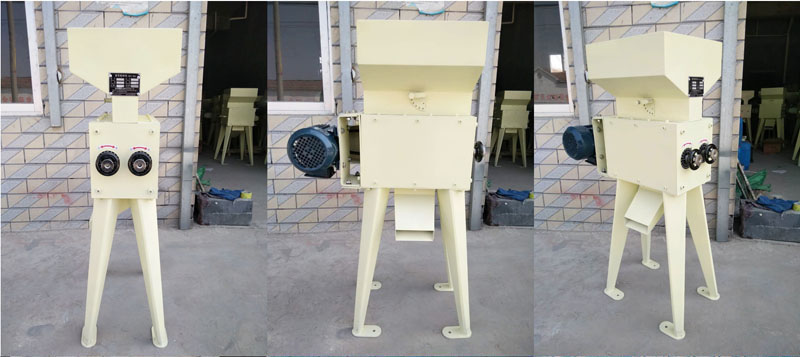

Mill System |

|||

|

Code |

Name |

Quantity |

Technical Parameter |

|

01 |

Mill Machine |

1 piece |

500Kg/h;

Breaker Roll Type; Adjustable mill degree; Power:2.2kw; Voltage:380V; Model:Fm-011; Faster Roller Speed: 700rpm Crushing Particle Size: Adjustable Ratio of Magnetic Metal Material:≤0.003g/kg Temperature of Rollers after Production:≤56℃ |

|

02 |

Malt screw auger |

1 piece |

Capacity:1000kg-3000kg/h;

Power:1.5Kw; |

Mash system |

|||

|

Code |

Name |

Size/ Volume/ Quantity |

Technical Parameter |

|

01 |

Mash/Lauter tank

Boiling/whirlpool tank hot water tank |

Double wall stainless steel

Gross capacity:2600L Useful capacity:2000L Outer :Ø1700 mm; Total height: 2600 mm; Top of tank manhole size:φ350 Filter board gap≤0.7mm Mix power:1.5KW Mixing ratio:1:43 |

Features: Grain mashing, Lautering and sparging

1.Material:Inner(SUS304),thickness:3.0mm; Out(SUS304),thinckness:2.0mm; 2. External-Jacket(SUS 304 thickness: 3.0mm; 3. Cylinder (sharp type, SUS304), thickness: 3.0mm. 4. Inner surface treatment: welds grinded to Ra 0.4µm without dead corner. 5. 100% TIG welding with pure argon gas shield 6. Insulation: Polyurethane-thickness 100 mm. 7. Dished top and conical bottom 8. Glass top manhole 9. Temperature way:Double metal thermometer 10. Outsourcing surface: Weld polishing processing 11. Jacket Pressure: design pressure 0.3 MPa, working pressure <0.2 MPa. 12. Top mounted 360° coverage CIP spraying ball and port TC Easy clean 13. Stainless steel laser cutting False Bottom/Filter 14. Thermo well for high accuracy temperature sensor 15. 4pcs completely SUS304 heavy duty legs with leveling

18.With sight light on top |

|

04 |

Wort pump VFD CONTROL; ABB MOTOR

|

– 2pcs

|

Capacity:5000L/h

Stainless steel 304 food deliver pump; Power:1.5KW, lift:38m, Rev:2880r/min The use of advanced inverter control of motors, energy-saving mute. The Motor speed can be controlled and adjusted by transducer. |

|

06 |

Detailed description of brewhouse pipeline | – 1set | 1.Hard pipings: Sanitary SUS304; Self-draining

Inline sight glass for checking wort clarity and color 2.12 meter sanitary reinforced brewery hose with TC adaptors 3. Pipe filter keeping hot break from heat exchanger 4.Complete valves, fittings and all parts 5.Every weld to a smooth sanitary finish |

|

07 |

Two stage plate heat exchanger | 1 pieces | Function: Wort cooling

1.Two stages for glycol water and city/cold water (single stage for optional) 2.Completely 304 SS Corrugated plates 3.Stainless steel back plates (Carbon steel cover for optional) 4.Full detachable for regular thorough cleaning 5.Effective Cooling Area: 30M2 6.Design Pressure: 1.0Mpa 7.Design Temperature: 170℃ 8.City water, glycol water, wort inlet and outlet 9.Size: 310*425*1010mm |

|

08 |

Operation platform | –1set | Platform frame is constructed entirely of stainless steel with a stainless diamond plate deck. A stainless watertight electronics enclosure is mounted to the back of the platform. Stairs are constructed of stainless steel diamond plate deck material. Safety rail is constructed of stainless steel tube |

|

09 |

External wort Grant | –1set | Features: Buffer tank avoiding negative pressure in

lauter tun 1. Total wort volume approx 50L 2. Hinged stainless steel cover 3. Sight levlel glass 4. Drain valve 5. 304 stainless steel 6. All 38 sanitary tri-clamp connections |

|

10 |

Wort aeration assembly | –1set | Features:

1. Stainless steel pipe assembly 2. Aeration stone 3. O2 10mm NPT ball valve O2 disconnect 4. 38 Sanitary tri-clamp connections 5. Built in sight glass |

|

11 |

Hops filter | –1set | Features:

1.Superior SUS 304 2.The hops can be fully filtered out 3.Filter Precision is 80-200um 4.Type:DN25-DN100 |

Fermentation system |

|||

|

Code |

Name |

Size/ Quantity |

Technical Parameter |

|

01 |

Fermentation tank | -5pcs

Double wall stainless steel tank; Gross capacity:2500L Useful capacity:2000L Outer :Ø1500mm; Total height: 3300 mm; |

1. Material Inner (SUS304)thickness: 3.0mm; Outer(SUS304)thickness:2.0mm

2. External-Jacket(SUS304) thickness: 1.5mm; 3. Oval head cone bottom, thickness: 3.0mm. 4. Heat exchange area:5.1㎡ 5. Equipment with : cone 60°resist compression design,dripping 6. 100% TIG welding with pure argon gas shield 7. Interior Finish: Sanitary 2B finish, Pickled and Passivity; (8K Mirror finish optional) 8. Exterior Finish: Oil brushed finish(2B, 8K Mirror finish optional) 9. Interior full polished to 0.2~0.4 μm without dead corner 10. Insulated with high density Polyurethane foam 100mm 11. Glycol Jacket: Dimpled plate on cone and side 12. Stringent tank leakage test by water and pressured gas 13. Stringent Jacket leakage test by water and pressured gas 14. Sanitary side mounted manway with pressured door 15. TC connected CIP arm with 360° coverage spraying ball 16. CO2 blow-off arm with butterfly valve 17.Full sanitary metallic sealed sampling valve 18.Mechanical safe valve PVRV 2 bar on top 19.Hydraulic shock pressure gauge on CIP arm 20.Rotating racking arm and port on cone with butterfly valve 21.Tri clamp discharge arm with butterfly valve 22.Thermowell for high accuracy temperature sensor 23.4pcs completely SUS304 heavy duty legs with leveling pad and legs support 24.Complete valves, fittings and all parts 25.Dry hopping port 4” TC with solid end cap 26.Sanitary level tube and valves TC for special request 27.Pressure gauge Thermometer gauge Sample valve Dry Hop Port |

Cleaning system |

|||

|

01 |

Washing pump | 3000l/h

– 1pc |

SS anticorrosion pump, Power:0.75KW lift:18m Rev:2880r/min |

|

02 |

Alkali tank | Useful capacity:200L

– 1pc |

Stainless steel304, double wall with insulation Inner surface treatment: welds grinded to Ra 0.6µm. Material all adopt the international standard of 304 stainless steel, all welding are argon protection single-sided, double-sided forming.

|

|

03 |

Sterilization tank | Useful capacity:200L

– 1pc |

Stainless steel304, double wall with insulation Stainless steel304, thickness: 2mm Inner surface treatment: welds grinded to Ra 0.6µm. Material all adopt the international standard of 304 stainless steel, all welding are argon protection single-sided, double-sided forming.

|

|

04 |

Control box | – 1pc | Cabinet Material: Anti-power Plastic painting

Assembling Style: Wall mounted Type Electrical Components: World wide brand CE certificated CIP pump on/off Heating elecment on/off Temperature controller for special request Auto on/off Timer for heating for special request VFD control for CIP pump for special request |

Control system |

|||

| 01 | Mashing control | Manual operate

Instrument Semi-Auto-control German TUV Certification Control Cabinet European standard Siemens,Schneider,Omron component 1 set |

Mixing, rotation, wort pump |

| 02 | Fermentign control | Temperature, pressure, lamp | |

| 03 | Cooling control | Machine unit, pump, temperature | |

| 04 | Cleaning control | Cleaning pump | |

| 05 | Hot water control | ||

| 06 | Glycol water tank control | ||

FAQ

1.Electric power:It can be customized according to customer’s local condition.Such as 220V,230V,380V,430V; 50HZ or 60HZ;3 phases or single phase.

2.Price:Every customer has different requirement,so we need to confirm your requirement first,then give you price.Such as some customer require steam heating,some customer require electric heating;Some customer require 2 vessels brewhouse and some customer require 3 vessels brewhouse;Some customer require top manhole for fermentation tank and some customer require side manhole.So even both 1000L equipment,there price are different.So we need to confirm your detailed requirement first.

3.How to see if your company is trust?

We have sold many equipment to EURO.We can give you our customer’s contact information,you can listen to their advice or visit their brewery.

4.How should we do if we don’t know how to brew beer and install equipment?

We will dispatch engineer to install equipment and teach you how to brew beer freely.

If you have interest,please get in touch with me freely.