Description

| To install a set of microbrewery equipment |

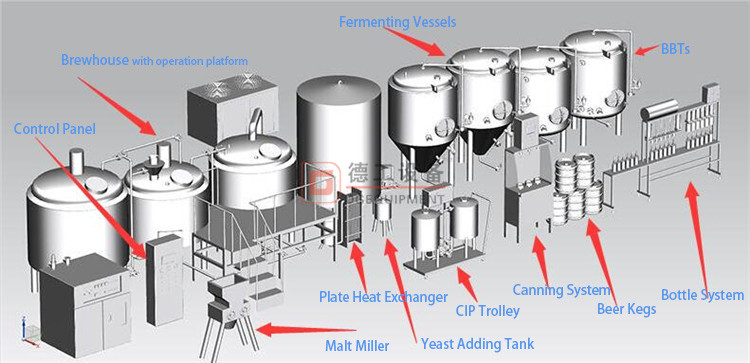

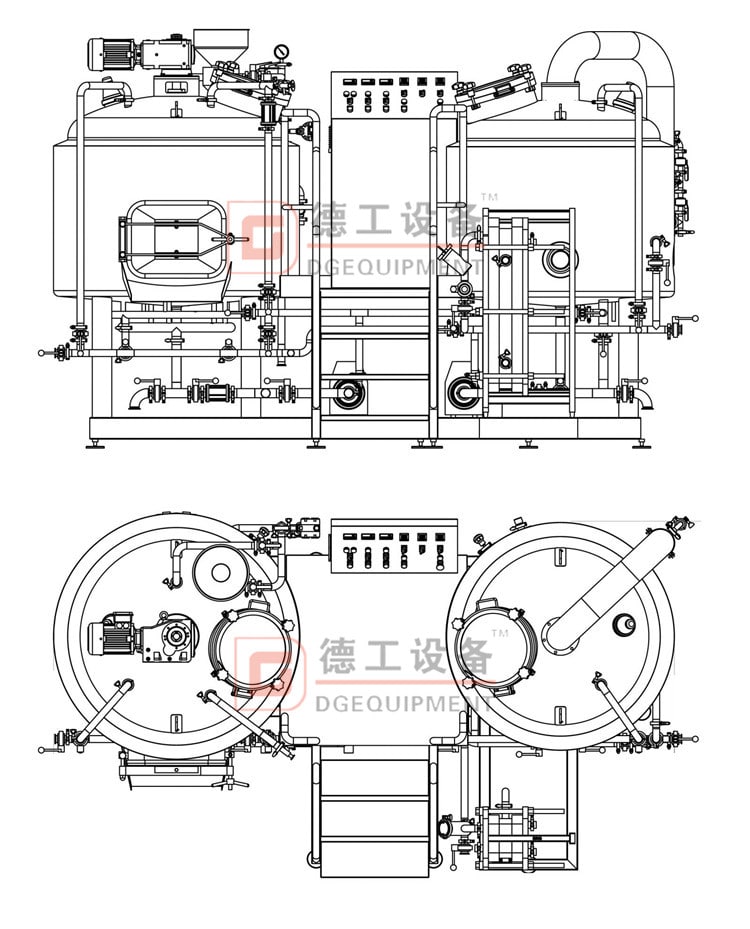

1.A mash-lauter system

A mash/ lauter tun (tank or vessel) is your primary piece.

Microbrewery(mash/lauter & kettle/whirlpool & hot liquor tank)

In it, you mash your malt and extract your sugar from the raw grain.

It will also serve as your lauter (lauter is to wash).

After the mash, run a specified amount of water through the mash to bring the volume of the wort up to capacity.

There will be an electric stainless-steel pump for transfer. You will fire the kettle with gas or a steam boiler.

The kettle is just this, a big pot for boiling. It is vented through the ceiling and will be direct fire with a gas burner or have steam jackets wrapping it. Steam is more efficient.

Turnkey brewery equipment

Of course, you also need a grain mill, which is a good choice for dual-rollers

You can buy pre-milled malt or crack your own for freshness and cost-savings.

A hot-liquor tank is for bulk hot water heating. You can live without it but not recommended. Its primary role is to heat water for mashing.

A cold liquor tank is useful.You keep cold water solely for cooling the wort after boiling.

Your brewhouse pump will transfer your raw wort through a heat exchanger. The heat exchanger is a tall block-shaped device made of layered plates. 200° wort goes in one side, 40° (or ambient) water goes in the other. This counterflow process cools your wort in 30-40 minutes. A cold liquor tank really comes in handy.

2-VESSEL Brewhouse system according to your needs

2.Fermentation systems

Fermenters are the vessels in which raw wort transforms into beer.

As seen in the photo, they are cylindroconical. They have a 60° cone that facilitates the drop out of solids once fermentation is complete: dead yeast, proteins, hops, and the healthy yeast too.

This is to effectively clarify the beer.

This is one of the time-consuming aspects of brewing.

Fermentation will last 7-14 days for ales and 21-35 days for lagers.

You will need to have ample fermentation equipment set up and ready to store and monitor the progress of your beer.

Brite tanks are beer tanks used for storage, conditioning, carbonation, and packaging. 1.They will have dish bottoms and sight glasses (a thin glass tube running the vertical height of the tank). 2.They will also have ports for a carbonation stone and sample cocks (small spigots) for measuring CO2 volumes.

3.They are cheaper than fermenters as the dish bottoms are single-walled and easier to make than cones.

Brewpubs will serve beer from brite tanks. In this case, you pay taxes based on the volume in the tank. Production brewers will pay taxes based on what makes it onto the pallet and into the walk-in, whether steel, bottle, or glass package.

They are cheaper than fermenters as the dish bottoms are single-walled and easier to make than cones.

Cellar tanks Fermentation tanks unitanks 500L

3.Cooling sytems

The wort is cooled down in order to bring it at the right temperature for fermentation. After the cooling, fermentation begins as yeats is put in the wort, taking place in a specific container called Fermentation Vessel. The equipment used in this step must be chosen carefully, as this is the most delicate process as far as hygiene is concerned.

4.Control systems

You will need to have temperature controls set up for your beer tanks.

The brewhouse (production area) switches can all be thrown manually. It depends on your budget and priorities for your brewery that determine what kind of switch system you have.

Controllers can also be viewed as safety measures you can use to halt production and prevent accidents in your facility.

5.Cleaning CIP system

You will need a portable CIP (clean-in-pace) tank that you can use for housing your sanitation solution, caustic (alkaline cleaner for organics) wash, and acid washes (largely for mineral build-up). It may have a built-in circulation pump, or can be paired with a portable pump.

| Contact Alice today |

Microbrewing, craft brewing or commercial large brewhouses, we have the equipment, supplies & install engineers. Looking to find bottling lines and tanks for sale we have that covered. If you want to more information for brewing process or buy beer equipment,please contact me.