Description

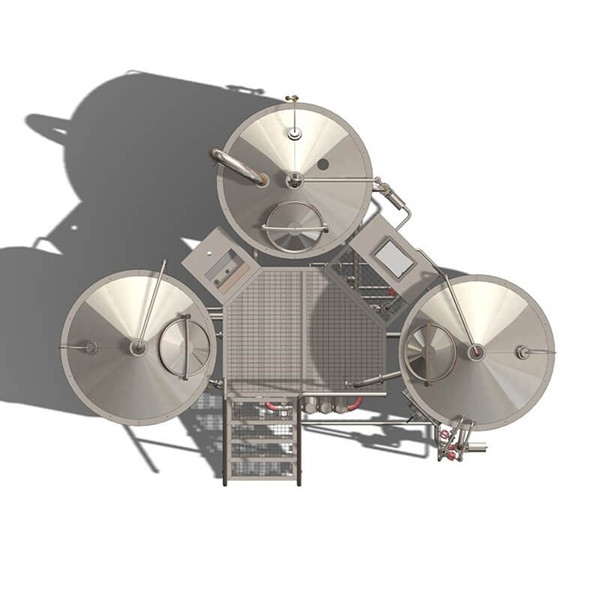

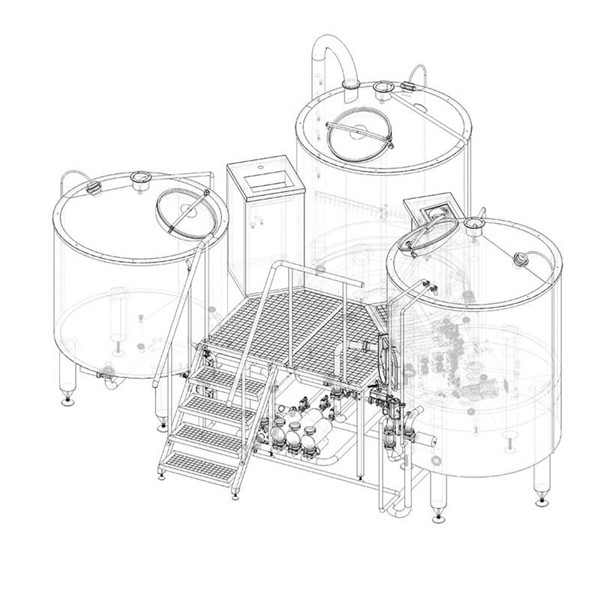

500L stainless steel customized pub brewery equipment for sale

Our experienced team of engineers work to design every brewhouse.

We meticulously focus on the details, like pump and valve placement, aiming to maximize brewhouse efficiency and ease of use.

2-vessel brewhouse:

2-vessel brewhouse configuration offer brewers a simple and cost effective solution. Through combining mash tun & lauter tun, and kettle & whirlpool into a 2-vessel solution, it will help you on space and cost saving without compromising brewing quality and control.

3-vessel brewhouse:

3-vessel brewhouse configurations offer brewers a more efficient and faster brewing solution and achieve multi temp. control for step mash. It can be comprised by mash/lauter, kettle/whirlpool, and hot water tank.

4-vessel brewhouse:

4-vessel brewhouse configuration offer brewers a professional and higher performance brewing solution for multi batches brew per day. It is comprised by mash, lauter, kettle, whirlpool. DG’s 4-vessel brewing system offer you options of semi-auto or automation controlling and overall flexibility.

Technical parameters(pub brewery equipment)

– All tanks are made of food grade stainless steel 304.

– Adopting advanced world famous brand components in electric parts and operation parts.

– ABB motor for wort pump

– ABB/Siemens motor for raker and blender

– PLC automatic control method

– The structure of brewhouse: 2-vessel, 3-vessel or 4-vessel (Optional)

– Thickness: inner 3.0mm; out 2.0mm; jacket: 1.5mm

– Insulation: Polyurethane thickness: 100mm

– Working pressure: 1.5-2.0 bar Design pressure: 3.0 bar

– Inner surface treatment: welds grinded to Ra0.4µm without dead corner

– Outsourcing surface: weld polishing processing

– Heating method: steam; electric; direct fire (Optional)

Pub brewery equipment details

Pub brewery equipment features:

–easy view all-glass wort grant

— mash agitators & lauter rake/plow systems

–food grade sanitary pumps

–stainless steel pump motors

–grist hydrator for pre-soaking during mash-in

–lauter floors

–single or dual-stage Thermaline plate heat exchanger

–glass top manways

–stainless steel brew platform

Optional:

–available from 50L to 20000L

–steam, direct-fire, & electric heating options

–two or three vessel arrangements

About us