Description

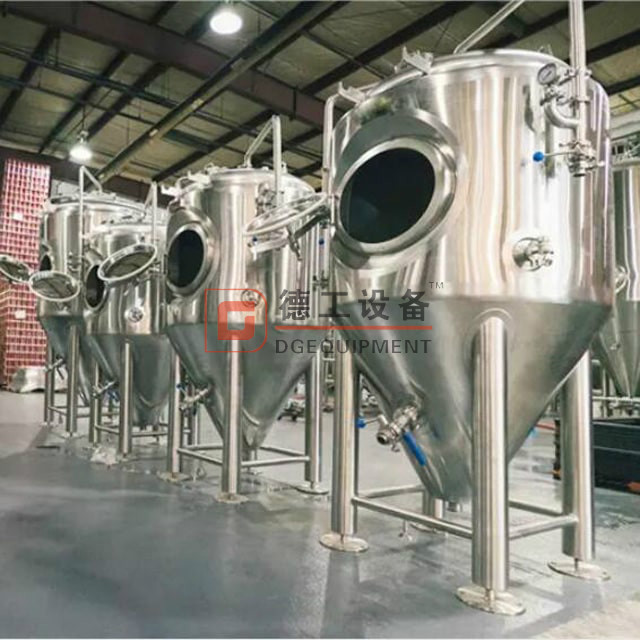

| Fermenting vessels introduction |

Fermentation is the process by which yeast converts the glucose in the wort to ethyl alcohol and carbon dioxide gas — giving the beer both its alcohol content and its carbonation.

Product features:

1)Our Fermentation tanks/tun available from 100L to 20000L (1 gallon to 20 gallon) and average 25% Head Space.

2) All tanks have a Dish top,

3)Cylinder body & 60° Cone Bottom.

4)Certified stainless steel(304,316) material for all tanks, with 100% TIG welded joints and seams with sanitary interior polish.

5) Dimple Plate jacket for Glycol cooling & high efficient Polyurethane foam insulated.

6)All tanks use Tri-clamp connections, are designed for testing at 3 bar.

7) We can customize fabricate any tank to meet your brewery’s space and height restrictions.

Side manway fermenting vessel in brewery

| Product description | ||

Installated fermenting vessel

60 degree conical;welding..

Our services:

Pre-sales Service:

1)Help the clients to confirm the configuration list

2)Supplying different beer craft specification

3)Designing the drawing according to the client’s floor plan and your requirement

4)Showing the detailed diagram of the tanks

After-sales Service:

1)We provide turnkey system, onsite installation service for brewery projects.

2)It’s available for us to send engineers to guide install

3)Life time guarantee

4)Online technology consult

| Contact Alice today |

Talk to us about your requirements and we will design a system to work for you and your company. wlcome to consult brewery to get a perfect quotation.