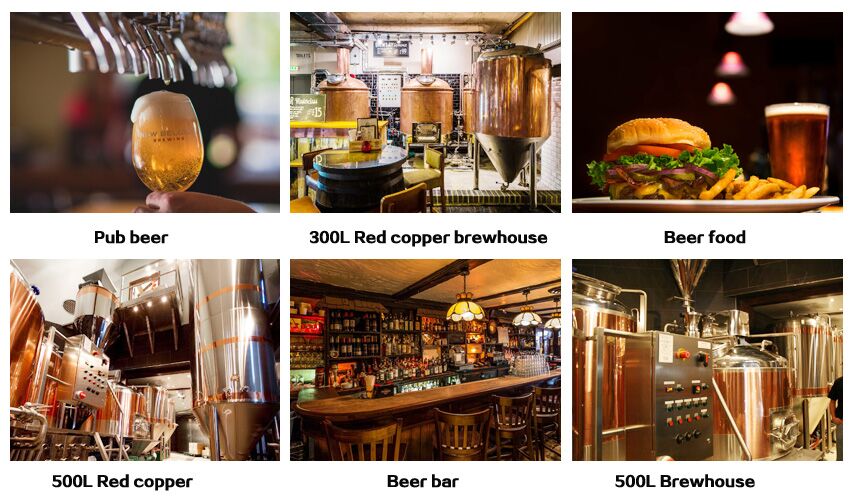

Description

Red copper beer brewery equipment is mainly used in beer pub, hotel, restaurant for the better appearance. All materials are sanitary food grade. Also the brand of motor for rake and blender is ABB or Siemens. The brewhouse will be built turnkey. Staff of my company will work together with you to fit every customer’s needs, from the design of drawing to the manufacturing of the equipment, our staff will build the equipment strictly according to the confirmed drawing. We design for best.

Red copper 500L beer brewhouse

- Customized red copper beer brewhouse ( can be combined type which is based on customer’s requests)

- Heating method: Gas, electric or steam heating method

- 150 degree or flat bottom, with 25% head space

- Stainless steel or copper operating platform(optional)

- Glass manhole which depends on customer’s request

- With all hard connecting pipes and valves, wort grant, sight glass

- With shadowless manhole

- ABB variable frequency wort pump

- Dual stage plate heating exchanger

- Red copper condensation pipe

- Interior mirror polishing & exterior 2B finish- cold-rolled, annealed, pickled

- Design pressure: 3 bar Working pressure: 1.5-2 bar

- ABB, Siemens motor for the rake and blender

- With internal CIP pipe

- Auto grain out system

- LED light

- Automatic or semi automatic control system

- This set of equipment is for micro brewery, especially for pub, restaurant, hotel, etc…

- Novel structure and attractive appearance

- More competitive price and better quality

- CE, ISO, TUV approved equipment

- More humanized design which allow you to operate easily

- Compact design saving your space

- All the materials touching the beer directly are all top quality food grade stainless steel.

- We use the first rate valves and manholes for all our equipments.

- I am here to guarantee all our customers that the materials are nonmagnetic.

- The thickness of the material exactly fit in with what showed in the specification sheet.

- If you are a new comer to the beer making field, Don’t worry, I will give you our professional recommendations. And the equipment must be top quality engineered.

- Engineer is always available to make the relative 2D and 3D drawings for you for your reference.

Our services:

– From 100L up to 100HL we plan custom made fully functional breweries incl. everything you need from malt mill to bottle filler. With more than 10 years of experience all over the world we are at your side from the first sketch making sure that you can start to brew according to your schedule.

– After importing and delivering all parts our engineering team will setup and install the brewery at your site. We only work with licensed specialists under the supervision of our technical department.

– With your successful brewery growing we provide you with customized solutions to expand your production volume. Brewhouse modifications, additional tanks, professional bottle filling lines what ever you need to make more customers happy we are at your service.

– In addition to specialized spare part supplies our team offers maintenance and repair service for brewhouse, tanks and filling lines. Making sure that your brewery always performs at its best. We can also relocate brewery equipment worldwide.

– Our service includes training your staff to use brewhouse and additional equipment. We also supervise quality control in order to guarantee premium beers with every batch. Courses on raw materials and glassware will broaden your team’s understanding for the joy of beer from the hop garden to the pub counter.

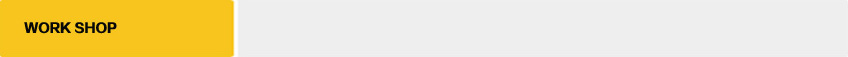

Contact us:

If you are interested in our brewery equipment, feel free to let me know.