Description

| Brewing equipment Product Description |

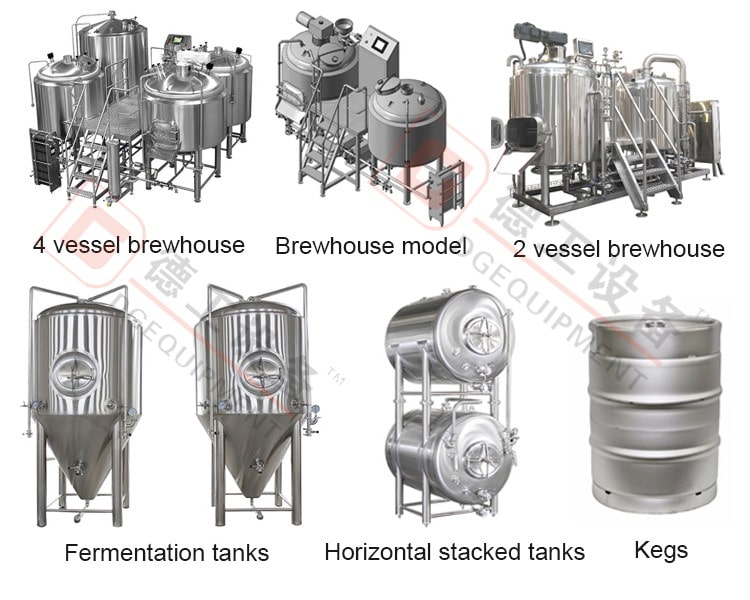

2000L beer brewery system produced by us is a set of technological equipment for the production of “live” and filtered beer, which includes miller-brewhosue(mash/lauter/kettle/whirlpool tun)-fermenter-bright beer tank-filter-glycol chilling unit-CIP-control panel -keg filler and rinser etc.

Brew master make their beer attractive to consumers by unique brewing process and distinctive beer taste. If desired, these beer brewingplant can be placed directly in places of consumption of beer: restaurants,brewpub, bars, hotels, tourist and shopping centers. Interpreter may be faced with polished brass, copper besides stainless steel.

Grist case top brewhouse,with grant

Brewery brewhouse tanks during the brewing process

A typical four-vessel brewhouse will include a Mash tun, Lauter Tun, Kettle and Whirlpool. Each of these tanks is dedicated to performing a single process, and is designed differently than similar vessel used for performing multiple processes.

Four-vessel brewhouse systems

Four brewhouse offer the highest throughput and the most versatility. With proper vessel sizing, well laid out hard piping, and well-designed controls these brewhouses can extremely large and only require one person to operate it. The ability to make more beer with less labor input, paired with gains in efficiency and quality control make the four-vessel brewhouse a worth while investment for breweries that intend to produce a lot of beer.

The alternative to a four-vessel production based brewhouse with dedicated process tanks, is two and three vessel systems with tanks that preform multiple processes. These combination tanks can be a more affordable way to start a brewery, they take up less floor space, and depending on your production goals, they might be able to last your business a very long time.

Two-vesssel brewhouse systems

Combination Mash Lauter Tuns are the first combination vessel in these smaller brewhouses line ups. Vessel size favor the Lauter operation, and have the mechanics for mixing mash and graining out.

Next inline is the combination of the Kettle and Whirlpool tanks. This combination vessel we designed and sized for being primarily a kettle, but is equipped with a tangential fitting for whirlpooling.

A three-vessel brewhouse

Three vessel brewhouse is hybrid system that incorporates at least one combination vessel and two dedicated process vessels. For example, a medium sized brewery with a focus on heavily hopped beers might choose to go with a combination Mash Lauter Tun, a dedicated Kettle, and a dedicated Whirlpool. Whereas, someone focusing on lagers or feeding a distilling operation might go with a dedicated Mash Tun, dedicated Lauter Tun, and a combination Kettle/Whirlpool. Three-vessel systems don’t have the same output and versatility as four-vessel systems, but they will still out perform a two-vessel system and provide increased efficiency.

| Main items | Main machine |

| Malt milling system | Double rollers malt miller machine |

| Saccharifying system |

Mash tun/lauter tun,brew kettle/whirlpool tun,wort pump, Mirror polishing Mechanical agitation:Stirring moter adopts variable frequency stepless speed control, improve wort preparation time. |

| Fermenting system |

Fermentation tank,inner tank adopts international standard food grade SUS304 All welding us double-sided welding argon gas protection,double-sided forming can improve the weld ability if under pressure. Mirror polishing |

| Heating system | Electric heating/ steam heating/ direct fire heating |

| Control system | Control cabinet, touch screen. Siemens PLC control |

| Chiller system | Ice water tank, cold water tank and pumps, plate heat exchanger, chiller |

| Filter system | Membrane filtration or plate filter machine or Diatomite filter |

| Storage system | Beer bright tank, beer storage tank |

| Cleaning system | CIP cleaning system, include alkali tank and disinfection tank,cleaning pump.Cleaning ball: internal comprehensive cleaning,improve the quality of internal cleaning. |

| Filling system | Manual and automatic bottle filling line, keg filler and washer machine |

| Selling system | beer selling tower, Beer selling tank, keg or bottle beer. |

Food grade construction fermenters double size of brewhouse

Fermentation tanks are where the magic happens. It’s important to have a precisely built vessel to condition your beer as it ferments.DEGONG offers fermentation tanks with ultra-precise welding and polishing, complete traceability, and material exactness to meet all international safety standards. From small, pub-size fermenters to towering outdoor tanks.

We have the manufacturing capability and expertise to custom-build fermentation tanks of all sizes.

- Function: Use for keep wort fermentation or maturation.

- Component:Shadowless manhole, Mechnical relief valve, Aseptic valve, Pressure gage, Rotate racking arm, Butterfly valve, Solenoid valve and etc.

- Glycol jacket: Dimpled plate on cone side, cooling media: glycol water.

- Cooling method: dimple plate or glycol cooling jacket around tank.

- Cooling media: glycol water.

Brewhouse and fermenting tanks shows:

Lauter tun spent grain hatch

Plate heat exchanger and wort pumps

Breather valve,pressure gauge;Aseptic sampling valve;discharge outlet.

CIP cleaning system

Grain miller

| Contact Alice today |

Talk to us about your requirements and we will design a brewing system to work for you and your company. wlcome to consult brewery to get a perfect quotation.